PDF Publication Title:

Text from PDF Page: 007

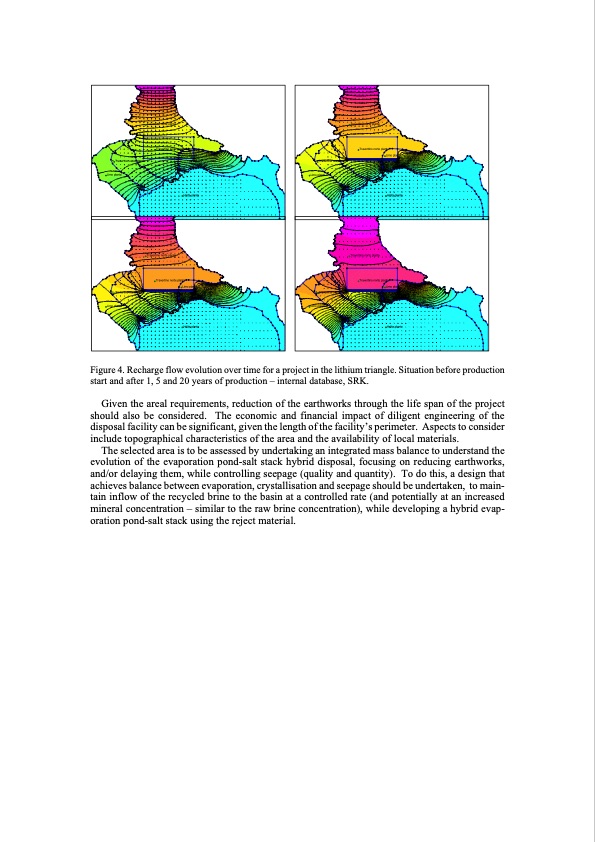

Travertino oeste planta Limo planta Travertino norte planta Travertino norte planta Limo planta Halita planta Limo planta Travertino oeste planta Limo planta Travertino norte planta Travertino norte planta Limo planta Halita planta Limo planta Travertino oeste planta Limo planta Travertino norte planta Travertino norte planta Limo planta Halita planta Limo planta Travertino oeste planta Limo planta Travertino norte planta Travertino norte planta Limo planta Halita planta Limo planta Figure 4. Recharge flow evolution over time for a project in the lithium triangle. Situation before production start and after 1, 5 and 20 years of production – internal database, SRK. Given the areal requirements, reduction of the earthworks through the life span of the project should also be considered. The economic and financial impact of diligent engineering of the disposal facility can be significant, given the length of the facility’s perimeter. Aspects to consider include topographical characteristics of the area and the availability of local materials. The selected area is to be assessed by undertaking an integrated mass balance to understand the evolution of the evaporation pond-salt stack hybrid disposal, focusing on reducing earthworks, and/or delaying them, while controlling seepage (quality and quantity). To do this, a design that achieves balance between evaporation, crystallisation and seepage should be undertaken, to main- tain inflow of the recycled brine to the basin at a controlled rate (and potentially at an increased mineral concentration – similar to the raw brine concentration), while developing a hybrid evap- oration pond-salt stack using the reject material.PDF Image | Direct extraction lithium processes

PDF Search Title:

Direct extraction lithium processesOriginal File Name Searched:

Ezama-Hoyos-Cortegoso-Braun-Spent_Brine_Disposal-TMW_Paper20191128190251287.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |