PDF Publication Title:

Text from PDF Page: 003

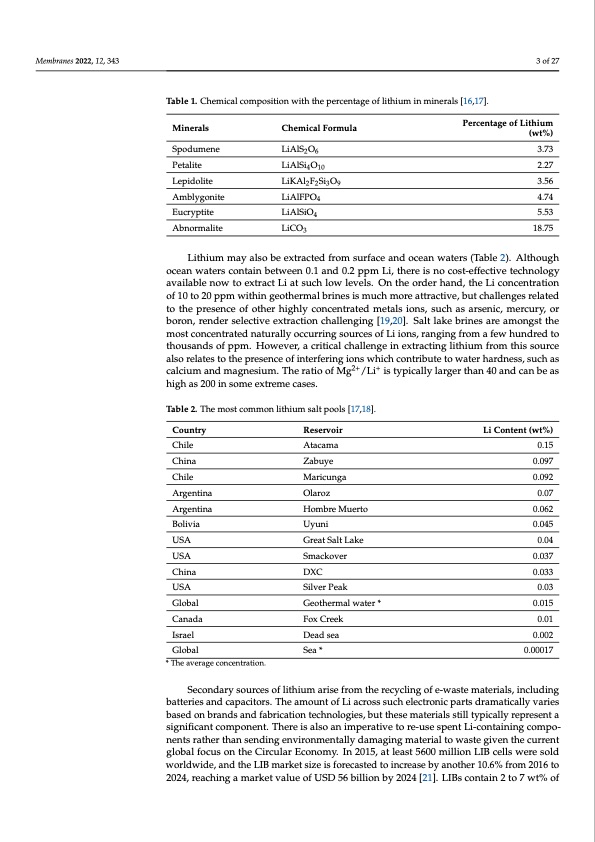

Membranes 2022, 12, 343 3 of 27 Table 1. Chemical composition with the percentage of lithium in minerals [16,17]. Minerals Spodumene Petalite Lepidolite Amblygonite Eucryptite Abnormalite Chemical Formula Percentage of Lithium (wt%) LiAlS2 O6 3.73 LiAlSi4 O10 2.27 LiKAl2 F2 Si3 O9 3.56 LiAlFPO4 4.74 LiAlSiO4 5.53 LiCO3 18.75 Lithium may also be extracted from surface and ocean waters (Table 2). Although ocean waters contain between 0.1 and 0.2 ppm Li, there is no cost-effective technology available now to extract Li at such low levels. On the order hand, the Li concentration of 10 to 20 ppm within geothermal brines is much more attractive, but challenges related to the presence of other highly concentrated metals ions, such as arsenic, mercury, or boron, render selective extraction challenging [19,20]. Salt lake brines are amongst the most concentrated naturally occurring sources of Li ions, ranging from a few hundred to thousands of ppm. However, a critical challenge in extracting lithium from this source also relates to the presence of interfering ions which contribute to water hardness, such as calcium and magnesium. The ratio of Mg2+/Li+ is typically larger than 40 and can be as high as 200 in some extreme cases. Table 2. The most common lithium salt pools [17,18]. Country Chile China Chile Argentina Argentina Bolivia USA USA China USA Global Canada Israel Global * The average concentration. Reservoir Li Content (wt%) Atacama 0.15 Zabuye Maricunga Olaroz Hombre Muerto Uyuni Great Salt Lake Smackover DXC Silver Peak Geothermal water * Fox Creek Dead sea Sea * 0.097 0.092 0.07 0.062 0.045 0.04 0.037 0.033 0.03 0.015 0.01 0.002 0.00017 Secondary sources of lithium arise from the recycling of e-waste materials, including batteries and capacitors. The amount of Li across such electronic parts dramatically varies based on brands and fabrication technologies, but these materials still typically represent a significant component. There is also an imperative to re-use spent Li-containing compo- nents rather than sending environmentally damaging material to waste given the current global focus on the Circular Economy. In 2015, at least 5600 million LIB cells were sold worldwide, and the LIB market size is forecasted to increase by another 10.6% from 2016 to 2024, reaching a market value of USD 56 billion by 2024 [21]. LIBs contain 2 to 7 wt% ofPDF Image | Electro-Driven Materials and Processes for Lithium

PDF Search Title:

Electro-Driven Materials and Processes for LithiumOriginal File Name Searched:

membranes-12-00343-v3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |