PDF Publication Title:

Text from PDF Page: 008

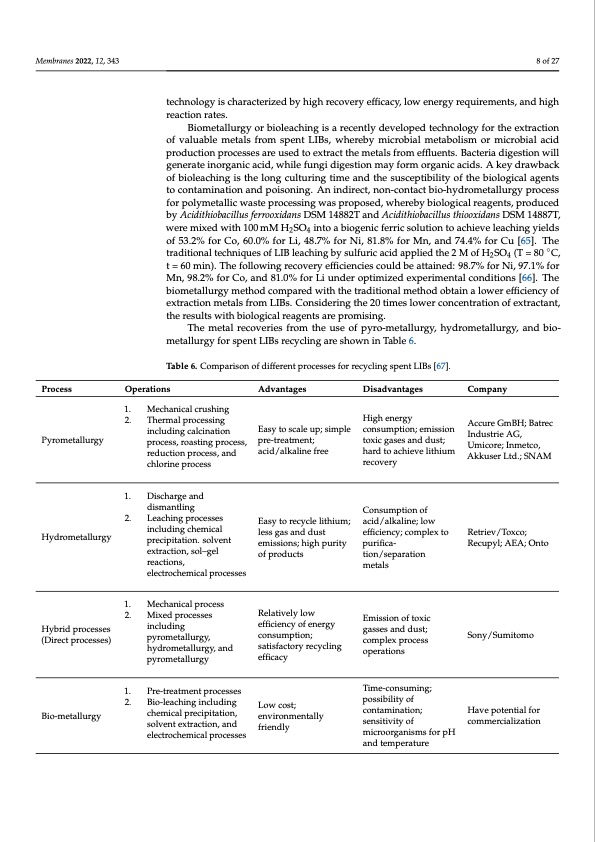

Membranes 2022, 12, 343 8 of 27 Process Pyrometallurgy Hydrometallurgy Hybrid processes (Direct processes) Bio-metallurgy Operations 1. Mechanical crushing 2. Thermal processing including calcination process, roasting process, reduction process, and chlorine process 1. Discharge and dismantling 2. Leaching processes including chemical precipitation. solvent extraction, sol–gel reactions, electrochemical processes 1. Mechanical process 2. Mixed processes including pyrometallurgy, hydrometallurgy, and pyrometallurgy 1. Pre-treatment processes 2. Bio-leaching including chemical precipitation, solvent extraction, and electrochemical processes Advantages Easy to scale up; simple pre-treatment; acid/alkaline free Easy to recycle lithium; less gas and dust emissions; high purity of products Relatively low efficiency of energy consumption; satisfactory recycling efficacy Low cost; environmentally friendly Disadvantages High energy consumption; emission toxic gases and dust; hard to achieve lithium recovery Consumption of acid/alkaline; low efficiency; complex to purifica- tion/separation metals Emission of toxic gasses and dust; complex process operations Time-consuming; possibility of contamination; sensitivity of microorganisms for pH and temperature Company Accure GmBH; Batrec Industrie AG, Umicore; Inmetco, Akkuser Ltd.; SNAM Retriev/Toxco; Recupyl; AEA; Onto Sony/Sumitomo Have potential for commercialization technology is characterized by high recovery efficacy, low energy requirements, and high reaction rates. Biometallurgy or bioleaching is a recently developed technology for the extraction of valuable metals from spent LIBs, whereby microbial metabolism or microbial acid production processes are used to extract the metals from effluents. Bacteria digestion will generate inorganic acid, while fungi digestion may form organic acids. A key drawback of bioleaching is the long culturing time and the susceptibility of the biological agents to contamination and poisoning. An indirect, non-contact bio-hydrometallurgy process for polymetallic waste processing was proposed, whereby biological reagents, produced by Acidithiobacillus ferrooxidans DSM 14882T and Acidithiobacillus thiooxidans DSM 14887T, were mixed with 100 mM H2SO4 into a biogenic ferric solution to achieve leaching yields of 53.2% for Co, 60.0% for Li, 48.7% for Ni, 81.8% for Mn, and 74.4% for Cu [65]. The traditional techniques of LIB leaching by sulfuric acid applied the 2 M of H2SO4 (T = 80 ◦C, t = 60 min). The following recovery efficiencies could be attained: 98.7% for Ni, 97.1% for Mn, 98.2% for Co, and 81.0% for Li under optimized experimental conditions [66]. The biometallurgy method compared with the traditional method obtain a lower efficiency of extraction metals from LIBs. Considering the 20 times lower concentration of extractant, the results with biological reagents are promising. The metal recoveries from the use of pyro-metallurgy, hydrometallurgy, and bio- metallurgy for spent LIBs recycling are shown in Table 6. Table 6. Comparison of different processes for recycling spent LIBs [67].PDF Image | Electro-Driven Materials and Processes for Lithium

PDF Search Title:

Electro-Driven Materials and Processes for LithiumOriginal File Name Searched:

membranes-12-00343-v3.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |