PDF Publication Title:

Text from PDF Page: 005

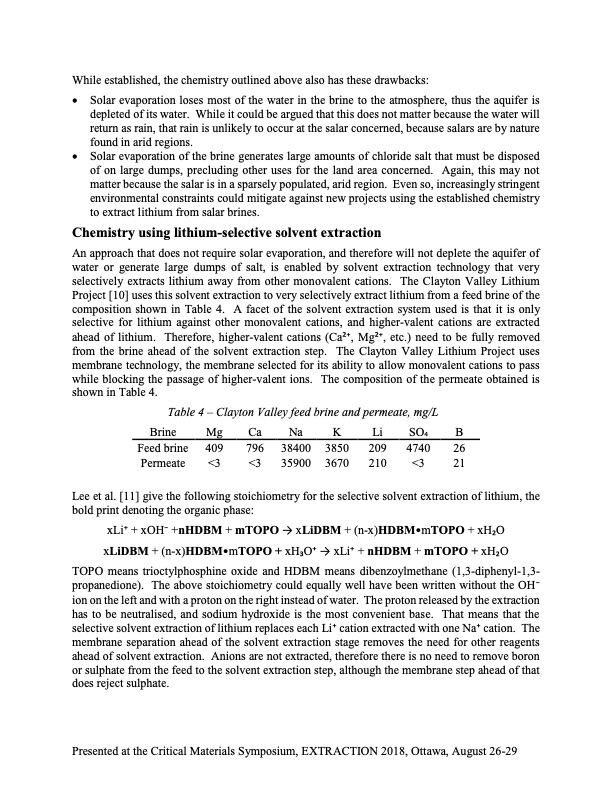

While established, the chemistry outlined above also has these drawbacks: • Solar evaporation loses most of the water in the brine to the atmosphere, thus the aquifer is depleted of its water. While it could be argued that this does not matter because the water will return as rain, that rain is unlikely to occur at the salar concerned, because salars are by nature found in arid regions. • Solar evaporation of the brine generates large amounts of chloride salt that must be disposed of on large dumps, precluding other uses for the land area concerned. Again, this may not matter because the salar is in a sparsely populated, arid region. Even so, increasingly stringent environmental constraints could mitigate against new projects using the established chemistry to extract lithium from salar brines. Chemistry using lithium-selective solvent extraction An approach that does not require solar evaporation, and therefore will not deplete the aquifer of water or generate large dumps of salt, is enabled by solvent extraction technology that very selectively extracts lithium away from other monovalent cations. The Clayton Valley Lithium Project [10] uses this solvent extraction to very selectively extract lithium from a feed brine of the composition shown in Table 4. A facet of the solvent extraction system used is that it is only selective for lithium against other monovalent cations, and higher-valent cations are extracted ahead of lithium. Therefore, higher-valent cations (Ca2+, Mg2+, etc.) need to be fully removed from the brine ahead of the solvent extraction step. The Clayton Valley Lithium Project uses membrane technology, the membrane selected for its ability to allow monovalent cations to pass while blocking the passage of higher-valent ions. The composition of the permeate obtained is shown in Table 4. Table 4 – Clayton Valley feed brine and permeate, mg/L Brine Mg Ca Na K Li SO4 B Feed brine 409 796 38400 3850 209 4740 26 Permeate <3 <3 35900 3670 210 <3 21 Lee et al. [11] give the following stoichiometry for the selective solvent extraction of lithium, the bold print denoting the organic phase: xLi+ + xOH− +nHDBM + mTOPO → xLiDBM + (n-x)HDBM•mTOPO + xH2O xLiDBM + (n-x)HDBM•mTOPO + xH3O+ → xLi+ + nHDBM + mTOPO + xH2O TOPO means trioctylphosphine oxide and HDBM means dibenzoylmethane (1,3-diphenyl-1,3- propanedione). The above stoichiometry could equally well have been written without the OH− ion on the left and with a proton on the right instead of water. The proton released by the extraction has to be neutralised, and sodium hydroxide is the most convenient base. That means that the selective solvent extraction of lithium replaces each Li+ cation extracted with one Na+ cation. The membrane separation ahead of the solvent extraction stage removes the need for other reagents ahead of solvent extraction. Anions are not extracted, therefore there is no need to remove boron or sulphate from the feed to the solvent extraction step, although the membrane step ahead of that does reject sulphate. Presented at the Critical Materials Symposium, EXTRACTION 2018, Ottawa, August 26-29PDF Image | Extraction of Lithium from Brine Chemistry

PDF Search Title:

Extraction of Lithium from Brine ChemistryOriginal File Name Searched:

Extraction of Lithium from Brine 13 Old and New Chemistry.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |