PDF Publication Title:

Text from PDF Page: 012

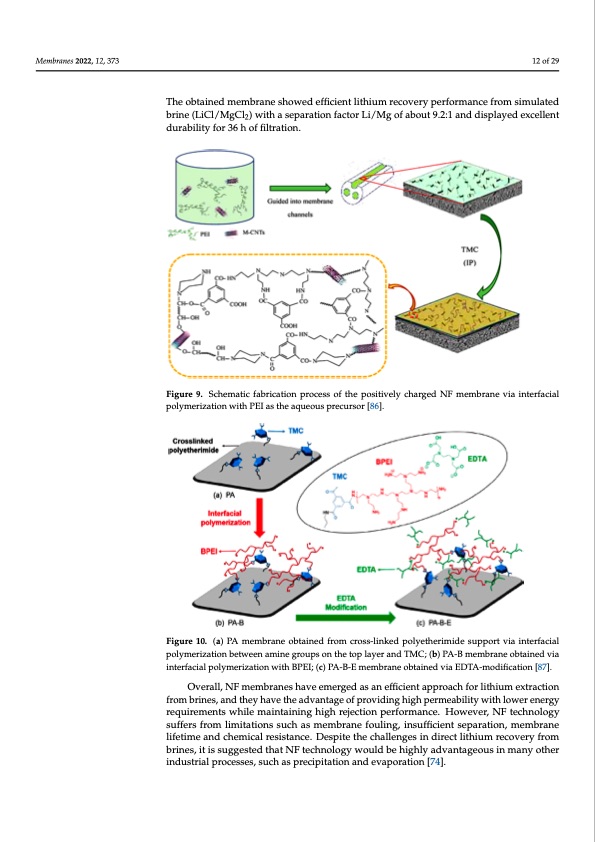

Zhang et al. fabricated a positively charged NF membrane through interfacial and sulfonated poly-phenyl ether ketone (SPPESK) in the synthesis of hydrophilic na- Membranes 2022, 12, 373 polymerization—with a polyethersulfone (PES) three-channel capillary UF membrane as the substrate and polyethyleneimine (PEI) as the aqueous precursor (Figure 9) [86]. The membrane exhibited long durability and good separation performance for Mg2+ and Li+ when applied to separate mixed salts solution simulating the composition of salt lake 12 of 29 via interfacial polymerization between branched poly (ethylene imine) (BPEI) and tri- mesoyl chloride (TMC) with crosslinked polyetherimide as the support (Figure 10) [87]. Membranes 2022, 12, x Figure 9. Schematic fabrication process of the positively charged NF membrane via int1e3rfaocfia2l9 Figure 9. Schematic fabrication process of the positively charged NF membrane via interfacial brine. Li et al. synthesized a composite NF membrane with a positively charged skin layer The obtained membrane showed efficient lithium recovery performance from simulated The obtained membrane showed efficient lithium recovery performance from simulated brine (LiCl/MgCl2) with a separation factor Li/Mg of about 9.2:1 and displayed excellent brine (LiCl/MgCl2) with a separation factor Li/Mg of about 9.2:1 and displayed excellent durability for 36 h of filtration. durability for 36 h of filtration. polymerization with PEI as the aqueous precursor [86]. polymerization with PEI as the aqueous precursor [86]. Overall, NF membranes have emerged as an efficient approach for lithium extraction from brines, and they have the advantage of providing high permeability with lower en- ergy requirements while maintaining high rejection performance. However, NF technol- ogy suffers from limitations such as membrane fouling, insufficient separation, membrane lifetime and chemical resistance. Despite the challenges in direct lithium recovery from brines, it is suggested that NF technology would be highly advantageous in many other industrial processes, such as precipitation and evaporation [74]. Figure 10. (a) PA membrane obtained from cross-linked polyetherimide support via interfacial Figure 10. (a) PA membrane obtained from cross-linked polyetherimide support via interfacial polymerization between amine groups on the top layer and TMC; (b) PA-B membrane obtained via polymerization between amine groups on the top layer and TMC; (b) PA-B membrane obtained via interfacial polymerization with BPEI; (c) PA-B-E membrane obtained via EDTA-modification [87]. interfacial polymerization with BPEI; (c) PA-B-E membrane obtained via EDTA-modification [87]. 3.2.2. Membrane Solvent Extraction Overall, NF membranes have emerged as an efficient approach for lithium extraction Owing to the promising performance shown in solvent extraction (see Section 3.1.2 from brines, and they have the advantage of providing high permeability with lower energy solvent extraction for more details), recent attention has been drawn to the fabrication of requirements while maintaining high rejection performance. However, NF technology membranes which support such extractions. The membranes are used to promote the sol- suffers from limitations such as membrane fouling, insufficient separation, membrane vents ability to extract the desire materials, and hence reduce the volume of waste typi- lifetime and chemical resistance. Despite the challenges in direct lithium recovery from cally produced by solvent extraction alone. Creating a homogeneous interface, these op- brines, it is suggested that NF technology would be highly advantageous in many other erations use supported liquid membranes (SLMs) which have previously demonstrated industrial processes, such as precipitation and evaporation [74]. high selectivity and low energy utilization [88,89]. SLMs have been the subject of many recent investigations for the separation of metal ions from industrial waste effluents using a variety of extractants. For example, they could act as ion exchange membranes for the lithium ions whilst blocking the organic solvent from passage to an aqueous solution [88]. In a recent study, successful lithium separation via SLMs has been achieved by complex- ation or binding with specific chemical species. Song et al. studied polyethersulfone (PES)PDF Image | Lithium Harvesting using Membranes

PDF Search Title:

Lithium Harvesting using MembranesOriginal File Name Searched:

membranes-12-00373-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |