PDF Publication Title:

Text from PDF Page: 012

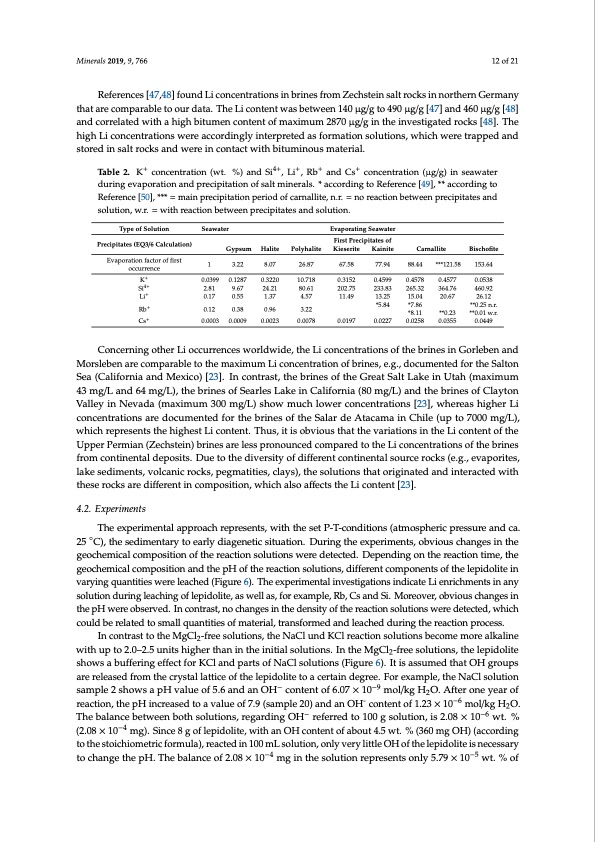

Minerals 2019, 9, 766 12 of 21 References [47,48] found Li concentrations in brines from Zechstein salt rocks in northern Germany that are comparable to our data. The Li content was between 140 μg/g to 490 μg/g [47] and 460 μg/g [48] and correlated with a high bitumen content of maximum 2870 μg/g in the investigated rocks [48]. The high Li concentrations were accordingly interpreted as formation solutions, which were trapped and stored in salt rocks and were in contact with bituminous material. Table 2. K+ concentration (wt. %) and Si4+, Li+, Rb+ and Cs+ concentration (μg/g) in seawater during evaporation and precipitation of salt minerals. * according to Reference [49], ** according to Reference [50], *** = main precipitation period of carnallite, n.r. = no reaction between precipitates and solution, w.r. = with reaction between precipitates and solution. Type of Solution Precipitates (EQ3/6 Calculation) Evaporation factor of first occurrence K+ Si4+ Li+ Rb+ Cs+ Seawater Gypsum 1 3.22 0.0399 0.1287 2.81 9.67 0.17 0.55 0.12 0.38 0.0003 0.0009 Evaporating Seawater First Precipitates of Halite 8.07 0.3220 24.21 1.37 0.96 0.0023 Polyhalite 26.87 10.718 80.61 4.57 3.22 0.0078 Kieserite 67.58 0.3152 202.75 11.49 0.0197 Kainite Carnallite Bischofite 153.64 0.0538 460.92 26.12 **0.25 n.r. **0.01 w.r. 0.0449 77.94 88.44 0.4599 0.4578 233.83 265.32 13.25 15.04 *5.84 *7.86 *8.11 0.0227 0.0258 ***121.58 0.4577 364.76 20.67 **0.23 0.0355 Concerning other Li occurrences worldwide, the Li concentrations of the brines in Gorleben and Morsleben are comparable to the maximum Li concentration of brines, e.g., documented for the Salton Sea (California and Mexico) [23]. In contrast, the brines of the Great Salt Lake in Utah (maximum 43 mg/L and 64 mg/L), the brines of Searles Lake in California (80 mg/L) and the brines of Clayton Valley in Nevada (maximum 300 mg/L) show much lower concentrations [23], whereas higher Li concentrations are documented for the brines of the Salar de Atacama in Chile (up to 7000 mg/L), which represents the highest Li content. Thus, it is obvious that the variations in the Li content of the Upper Permian (Zechstein) brines are less pronounced compared to the Li concentrations of the brines from continental deposits. Due to the diversity of different continental source rocks (e.g., evaporites, lake sediments, volcanic rocks, pegmatities, clays), the solutions that originated and interacted with these rocks are different in composition, which also affects the Li content [23]. 4.2. Experiments The experimental approach represents, with the set P-T-conditions (atmospheric pressure and ca. 25 ◦C), the sedimentary to early diagenetic situation. During the experiments, obvious changes in the geochemical composition of the reaction solutions were detected. Depending on the reaction time, the geochemical composition and the pH of the reaction solutions, different components of the lepidolite in varying quantities were leached (Figure 6). The experimental investigations indicate Li enrichments in any solution during leaching of lepidolite, as well as, for example, Rb, Cs and Si. Moreover, obvious changes in the pH were observed. In contrast, no changes in the density of the reaction solutions were detected, which could be related to small quantities of material, transformed and leached during the reaction process. In contrast to the MgCl2-free solutions, the NaCl und KCl reaction solutions become more alkaline with up to 2.0–2.5 units higher than in the initial solutions. In the MgCl2-free solutions, the lepidolite shows a buffering effect for KCl and parts of NaCl solutions (Figure 6). It is assumed that OH groups are released from the crystal lattice of the lepidolite to a certain degree. For example, the NaCl solution sample 2 shows a pH value of 5.6 and an OH− content of 6.07 × 10−9 mol/kg H2O. After one year of reaction, the pH increased to a value of 7.9 (sample 20) and an OH- content of 1.23 × 10−6 mol/kg H2O. The balance between both solutions, regarding OH− referred to 100 g solution, is 2.08 × 10−6 wt. % (2.08 × 10−4 mg). Since 8 g of lepidolite, with an OH content of about 4.5 wt. % (360 mg OH) (according to the stoichiometric formula), reacted in 100 mL solution, only very little OH of the lepidolite is necessary to change the pH. The balance of 2.08 × 10−4 mg in the solution represents only 5.79 × 10−5 wt. % ofPDF Image | Lithium Occurrences in Brines from Two German Salt Deposits

PDF Search Title:

Lithium Occurrences in Brines from Two German Salt DepositsOriginal File Name Searched:

minerals-09-00766-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |