PDF Publication Title:

Text from PDF Page: 008

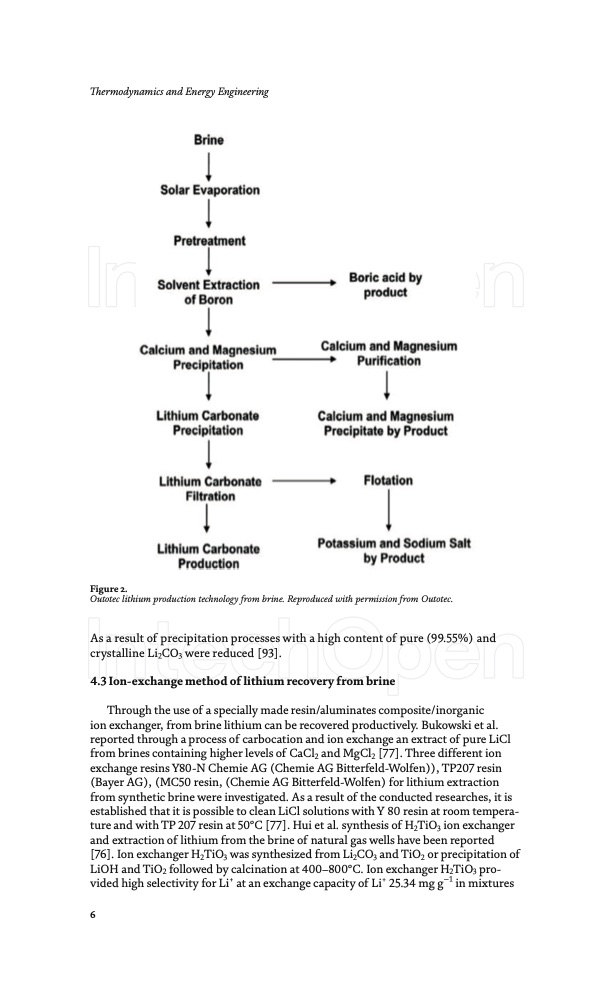

Thermodynamics and Energy Engineering Figure 2. Outotec lithium production technology from brine. Reproduced with permission from Outotec. As a result of precipitation processes with a high content of pure (99.55%) and crystalline Li2CO3 were reduced [93]. 4.3 Ion-exchange method of lithium recovery from brine Through the use of a specially made resin/aluminates composite/inorganic ion exchanger, from brine lithium can be recovered productively. Bukowski et al. reported through a process of carbocation and ion exchange an extract of pure LiCl from brines containing higher levels of CaCl2 and MgCl2 [77]. Three different ion exchange resins Y80-N Chemie AG (Chemie AG Bitterfeld-Wolfen)), TP207 resin (Bayer AG), (MC50 resin, (Chemie AG Bitterfeld-Wolfen) for lithium extraction from synthetic brine were investigated. As a result of the conducted researches, it is established that it is possible to clean LiCl solutions with Y 80 resin at room tempera- ture and with TP 207 resin at 50°C [77]. Hui et al. synthesis of H2TiO3 ion exchanger and extraction of lithium from the brine of natural gas wells have been reported [76]. Ion exchanger H2TiO3 was synthesized from Li2CO3 and TiO2 or precipitation of LiOH and TiO2 followed by calcination at 400–800°C. Ion exchanger H2TiO3 pro- vided high selectivity for Li+ at an exchange capacity of Li+ 25.34 mg g−1 in mixtures 6PDF Image | Lithium Recovery from Seawater Salt Lake Brine

PDF Search Title:

Lithium Recovery from Seawater Salt Lake BrineOriginal File Name Searched:

IntechOpenSamadiyBookchapter.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |