PDF Publication Title:

Text from PDF Page: 005

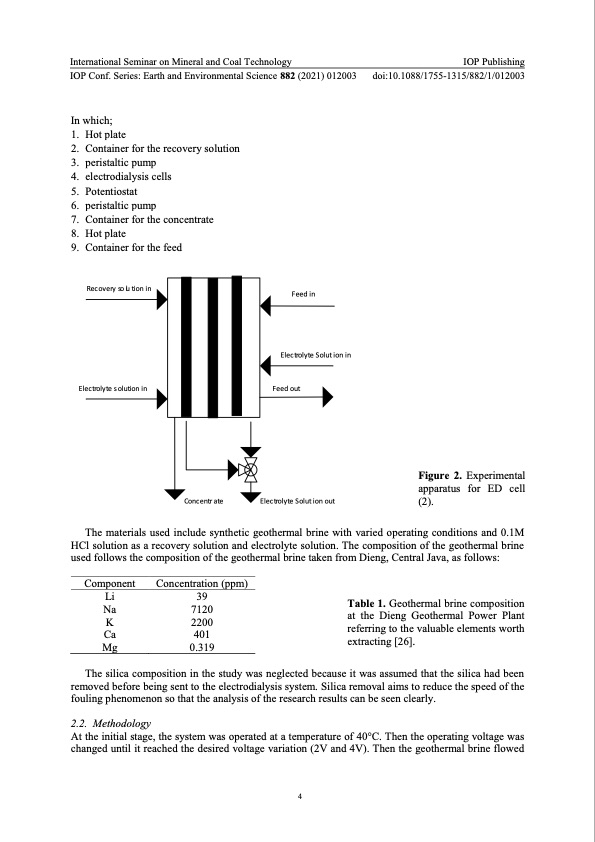

International Seminar on Mineral and Coal Technology IOP Conf. Series: Earth and Environmental Science 882 (2021) 012003 IOP Publishing doi:10.1088/1755-1315/882/1/012003 In which; 1. Hot plate 2. Container for the recovery solution 3. peristaltic pump 4. electrodialysis cells 5. Potentiostat 6. peristaltic pump 7. Container for the concentrate 8. Hot plate 9. Container for the feed Recovery so lu tion in Electrolyte solution in Feed in Electrolyte Solut ion in Feed out Electrolyte Solut ion out Concentr ate Figure 2. Experimental apparatus for ED cell (2). The materials used include synthetic geothermal brine with varied operating conditions and 0.1M HCl solution as a recovery solution and electrolyte solution. The composition of the geothermal brine used follows the composition of the geothermal brine taken from Dieng, Central Java, as follows: Component Li Na K Ca Mg Concentration (ppm) 39 7120 2200 401 0.319 Table 1. Geothermal brine composition at the Dieng Geothermal Power Plant referring to the valuable elements worth extracting [26]. The silica composition in the study was neglected because it was assumed that the silica had been removed before being sent to the electrodialysis system. Silica removal aims to reduce the speed of the fouling phenomenon so that the analysis of the research results can be seen clearly. 2.2. Methodology At the initial stage, the system was operated at a temperature of 40°C. Then the operating voltage was changed until it reached the desired voltage variation (2V and 4V). Then the geothermal brine flowed 4PDF Image | Lithium recovery synthetic geothermal brine electrodialysis

PDF Search Title:

Lithium recovery synthetic geothermal brine electrodialysisOriginal File Name Searched:

lithium-from-brine-geothermal.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |