PDF Publication Title:

Text from PDF Page: 008

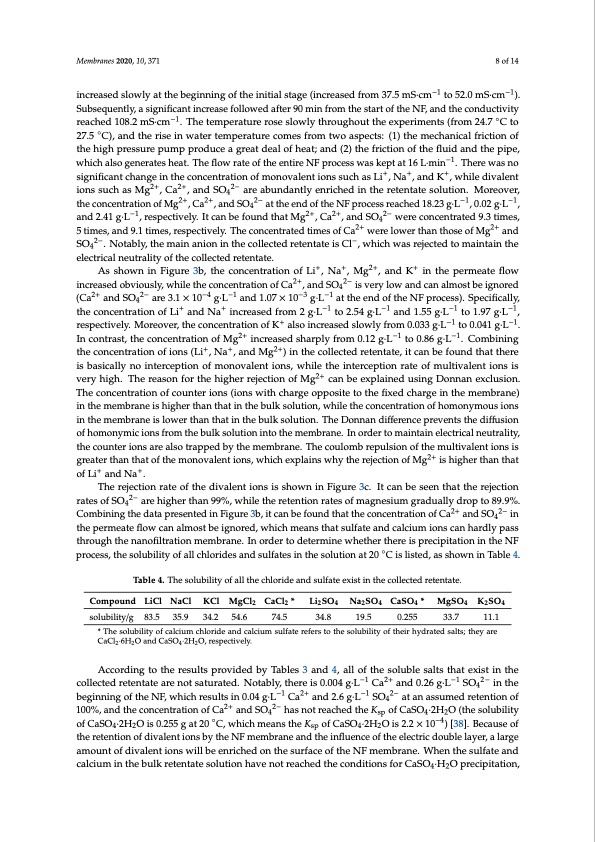

Membranes 2020, 10, 371 8 of 14 increased slowly at the beginning of the initial stage (increased from 37.5 mS·cm−1 to 52.0 mS·cm−1). Subsequently, a significant increase followed after 90 min from the start of the NF, and the conductivity reached 108.2 mS·cm−1. The temperature rose slowly throughout the experiments (from 24.7 ◦C to 27.5 ◦C), and the rise in water temperature comes from two aspects: (1) the mechanical friction of the high pressure pump produce a great deal of heat; and (2) the friction of the fluid and the pipe, which also generates heat. The flow rate of the entire NF process was kept at 16 L·min−1. There was no significant change in the concentration of monovalent ions such as Li+, Na+, and K+, while divalent ions such as Mg2+, Ca2+, and SO42− are abundantly enriched in the retentate solution. Moreover, the concentration of Mg2+, Ca2+, and SO42− at the end of the NF process reached 18.23 g·L−1, 0.02 g·L−1, and 2.41 g·L−1, respectively. It can be found that Mg2+, Ca2+, and SO42− were concentrated 9.3 times, 5 times, and 9.1 times, respectively. The concentrated times of Ca2+ were lower than those of Mg2+ and SO42−. Notably, the main anion in the collected retentate is Cl−, which was rejected to maintain the electrical neutrality of the collected retentate. As shown in Figure 3b, the concentration of Li+, Na+, Mg2+, and K+ in the permeate flow increased obviously, while the concentration of Ca2+, and SO42− is very low and can almost be ignored (Ca2+ and SO42− are 3.1 × 10−4 g·L−1 and 1.07 × 10−3 g·L−1 at the end of the NF process). Specifically, the concentration of Li+ and Na+ increased from 2 g·L−1 to 2.54 g·L−1 and 1.55 g·L−1 to 1.97 g·L−1, respectively. Moreover, the concentration of K+ also increased slowly from 0.033 g·L−1 to 0.041 g·L−1. In contrast, the concentration of Mg2+ increased sharply from 0.12 g·L−1 to 0.86 g·L−1. Combining the concentration of ions (Li+, Na+, and Mg2+) in the collected retentate, it can be found that there is basically no interception of monovalent ions, while the interception rate of multivalent ions is very high. The reason for the higher rejection of Mg2+ can be explained using Donnan exclusion. The concentration of counter ions (ions with charge opposite to the fixed charge in the membrane) in the membrane is higher than that in the bulk solution, while the concentration of homonymous ions in the membrane is lower than that in the bulk solution. The Donnan difference prevents the diffusion of homonymic ions from the bulk solution into the membrane. In order to maintain electrical neutrality, the counter ions are also trapped by the membrane. The coulomb repulsion of the multivalent ions is greater than that of the monovalent ions, which explains why the rejection of Mg2+ is higher than that of Li+ and Na+. The rejection rate of the divalent ions is shown in Figure 3c. It can be seen that the rejection rates of SO42− are higher than 99%, while the retention rates of magnesium gradually drop to 89.9%. Combining the data presented in Figure 3b, it can be found that the concentration of Ca2+ and SO42− in the permeate flow can almost be ignored, which means that sulfate and calcium ions can hardly pass through the nanofiltration membrane. In order to determine whether there is precipitation in the NF process, the solubility of all chlorides and sulfates in the solution at 20 ◦C is listed, as shown in Table 4. Table 4. The solubility of all the chloride and sulfate exist in the collected retentate. Compound LiCl NaCl KCl MgCl2 CaCl2 * Li2SO4 Na2SO4 CaSO4 * MgSO4 K2SO4 solubility/g 83.5 35.9 34.2 54.6 74.5 34.8 19.5 0.255 33.7 11.1 * The solubility of calcium chloride and calcium sulfate refers to the solubility of their hydrated salts; they are CaCl2·6H2O and CaSO4·2H2O, respectively. According to the results provided by Tables 3 and 4, all of the soluble salts that exist in the collected retentate are not saturated. Notably, there is 0.004 g·L−1 Ca2+ and 0.26 g·L−1 SO42− in the beginning of the NF, which results in 0.04 g·L−1 Ca2+ and 2.6 g·L−1 SO42− at an assumed retention of 100%, and the concentration of Ca2+ and SO42− has not reached the Ksp of CaSO4·2H2O (the solubility of CaSO4·2H2O is 0.255 g at 20 ◦C, which means the Ksp of CaSO4·2H2O is 2.2 × 10−4) [38]. Because of the retention of divalent ions by the NF membrane and the influence of the electric double layer, a large amount of divalent ions will be enriched on the surface of the NF membrane. When the sulfate and calcium in the bulk retentate solution have not reached the conditions for CaSO4·H2O precipitation,PDF Image | Membrane Process for Preparing Lithium Carbonate

PDF Search Title:

Membrane Process for Preparing Lithium CarbonateOriginal File Name Searched:

membranes-10-00371.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |