PDF Publication Title:

Text from PDF Page: 005

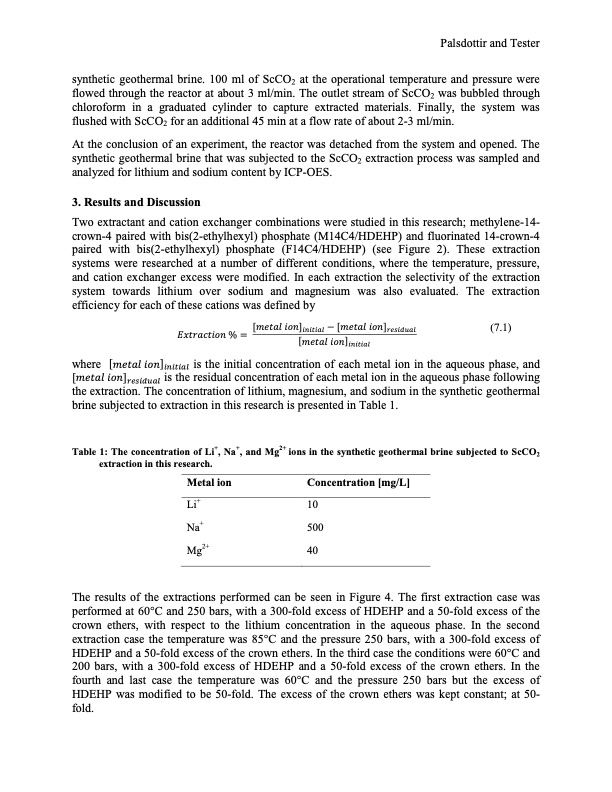

synthetic geothermal brine. 100 ml of ScCO2 at the operational temperature and pressure were flowed through the reactor at about 3 ml/min. The outlet stream of ScCO2 was bubbled through chloroform in a graduated cylinder to capture extracted materials. Finally, the system was flushed with ScCO2 for an additional 45 min at a flow rate of about 2-3 ml/min. At the conclusion of an experiment, the reactor was detached from the system and opened. The synthetic geothermal brine that was subjected to the ScCO2 extraction process was sampled and analyzed for lithium and sodium content by ICP-OES. 3. Results and Discussion Two extractant and cation exchanger combinations were studied in this research; methylene-14- crown-4 paired with bis(2-ethylhexyl) phosphate (M14C4/HDEHP) and fluorinated 14-crown-4 paired with bis(2-ethylhexyl) phosphate (F14C4/HDEHP) (see Figure 2). These extraction systems were researched at a number of different conditions, where the temperature, pressure, and cation exchanger excess were modified. In each extraction the selectivity of the extraction system towards lithium over sodium and magnesium was also evaluated. The extraction efficiency for each of these cations was defined by 𝐸𝑥𝑡𝑟𝑎𝑐𝑡𝑖𝑜𝑛 % = [𝑚𝑒𝑡𝑎𝑙 𝑖𝑜𝑛]𝑖𝑛𝑖𝑡𝑖𝑎𝑙 − [𝑚𝑒𝑡𝑎𝑙 𝑖𝑜𝑛]𝑟𝑒𝑠𝑖𝑑𝑢𝑎𝑙 (7.1) [𝑚𝑒𝑡𝑎𝑙 𝑖𝑜𝑛]𝑖𝑛𝑖𝑡𝑖𝑎𝑙 where [𝑚𝑒𝑡𝑎𝑙 𝑖𝑜𝑛]𝑖𝑛𝑖𝑡𝑖𝑎𝑙 is the initial concentration of each metal ion in the aqueous phase, and [𝑚𝑒𝑡𝑎𝑙 𝑖𝑜𝑛]𝑟𝑒𝑠𝑖𝑑𝑢𝑎𝑙 is the residual concentration of each metal ion in the aqueous phase following the extraction. The concentration of lithium, magnesium, and sodium in the synthetic geothermal brine subjected to extraction in this research is presented in Table 1. Palsdottir and Tester Table 1: The concentration of Li+, Na+, and Mg2+ ions in the synthetic geothermal brine subjected to ScCO2 extraction in this research. Metal ion Concentration [mg/L] Li+ 10 Na+ Mg2+ 500 40 The results of the extractions performed can be seen in Figure 4. The first extraction case was performed at 60°C and 250 bars, with a 300-fold excess of HDEHP and a 50-fold excess of the crown ethers, with respect to the lithium concentration in the aqueous phase. In the second extraction case the temperature was 85°C and the pressure 250 bars, with a 300-fold excess of HDEHP and a 50-fold excess of the crown ethers. In the third case the conditions were 60°C and 200 bars, with a 300-fold excess of HDEHP and a 50-fold excess of the crown ethers. In the fourth and last case the temperature was 60°C and the pressure 250 bars but the excess of HDEHP was modified to be 50-fold. The excess of the crown ethers was kept constant; at 50- fold.PDF Image | Mining the Future Lithium

PDF Search Title:

Mining the Future LithiumOriginal File Name Searched:

1034174.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |