PDF Publication Title:

Text from PDF Page: 004

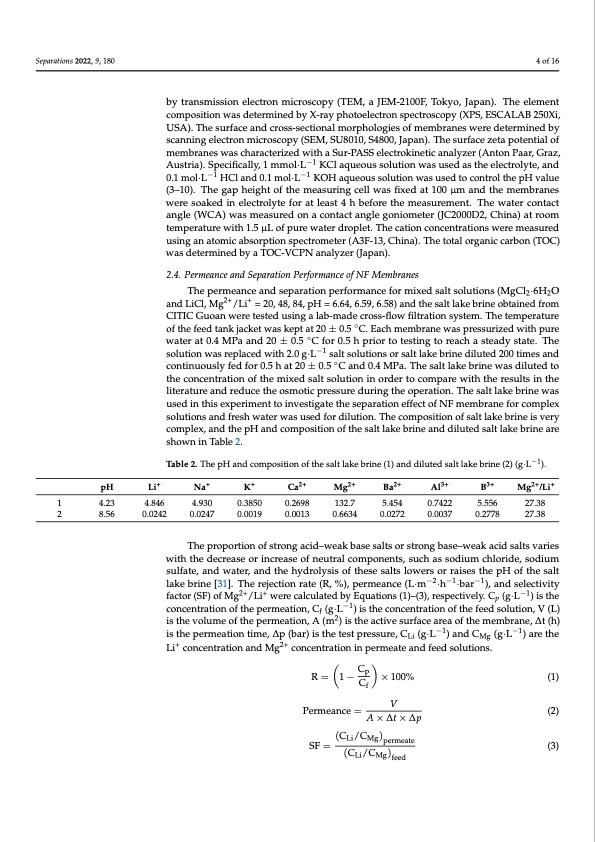

Separations 2022, 9, 180 4 of 16 by transmission electron microscopy (TEM, a JEM-2100F, Tokyo, Japan). The element composition was determined by X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi, USA). The surface and cross-sectional morphologies of membranes were determined by scanning electron microscopy (SEM, SU8010, S4800, Japan). The surface zeta potential of membranes was characterized with a Sur-PASS electrokinetic analyzer (Anton Paar, Graz, Austria). Specifically, 1 mmol·L−1 KCl aqueous solution was used as the electrolyte, and 0.1 mol·L−1 HCl and 0.1 mol·L−1 KOH aqueous solution was used to control the pH value (3–10). The gap height of the measuring cell was fixed at 100 μm and the membranes were soaked in electrolyte for at least 4 h before the measurement. The water contact angle (WCA) was measured on a contact angle goniometer (JC2000D2, China) at room temperature with 1.5 μL of pure water droplet. The cation concentrations were measured using an atomic absorption spectrometer (A3F-13, China). The total organic carbon (TOC) was determined by a TOC-VCPN analyzer (Japan). 2.4. Permeance and Separation Performance of NF Membranes The permeance and separation performance for mixed salt solutions (MgCl2·6H2O and LiCl, Mg2+/Li+ = 20, 48, 84, pH = 6.64, 6.59, 6.58) and the salt lake brine obtained from CITIC Guoan were tested using a lab-made cross-flow filtration system. The temperature of the feed tank jacket was kept at 20 ± 0.5 ◦C. Each membrane was pressurized with pure water at 0.4 MPa and 20 ± 0.5 ◦C for 0.5 h prior to testing to reach a steady state. The solution was replaced with 2.0 g·L−1 salt solutions or salt lake brine diluted 200 times and continuously fed for 0.5 h at 20 ± 0.5 ◦C and 0.4 MPa. The salt lake brine was diluted to the concentration of the mixed salt solution in order to compare with the results in the literature and reduce the osmotic pressure during the operation. The salt lake brine was used in this experiment to investigate the separation effect of NF membrane for complex solutions and fresh water was used for dilution. The composition of salt lake brine is very complex, and the pH and composition of the salt lake brine and diluted salt lake brine are shown in Table 2. Table 2. The pH and composition of the salt lake brine (1) and diluted salt lake brine (2) (g·L−1). pH 1 4.23 2 8.56 Li+ 4.846 0.0242 Na+ 4.930 0.0247 K+ 0.3850 0.0019 Ca2+ 0.2698 0.0013 Mg2+ 132.7 0.6634 Ba2+ 5.454 0.0272 Al3+ 0.7422 0.0037 B3+ 5.556 0.2778 Mg2+/Li+ 27.38 27.38 The proportion of strong acid–weak base salts or strong base–weak acid salts varies with the decrease or increase of neutral components, such as sodium chloride, sodium sulfate, and water, and the hydrolysis of these salts lowers or raises the pH of the salt lake brine [31]. The rejection rate (R, %), permeance (L·m−2·h−1·bar−1), and selectivity factor (SF) of Mg2+/Li+ were calculated by Equations (1)–(3), respectively. Cp (g·L−1) is the concentration of the permeation, Cf (g·L−1) is the concentration of the feed solution, V (L) is the volume of the permeation, A (m2) is the active surface area of the membrane, ∆t (h) is the permeation time, ∆p (bar) is the test pressure, CLi (g·L−1) and CMg (g·L−1) are the Li+ concentration and Mg2+ concentration in permeate and feed solutions. Cp R= 1−C ×100% (1) f Permeance = V (2) (3) (CLi /CMg )permeate SF = (CLi/CMg) A×∆t×∆p feedPDF Image | Nanofiltration Membrane Using Polydopamine Carbon Nitride

PDF Search Title:

Nanofiltration Membrane Using Polydopamine Carbon NitrideOriginal File Name Searched:

separations-09-00180.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |