PDF Publication Title:

Text from PDF Page: 003

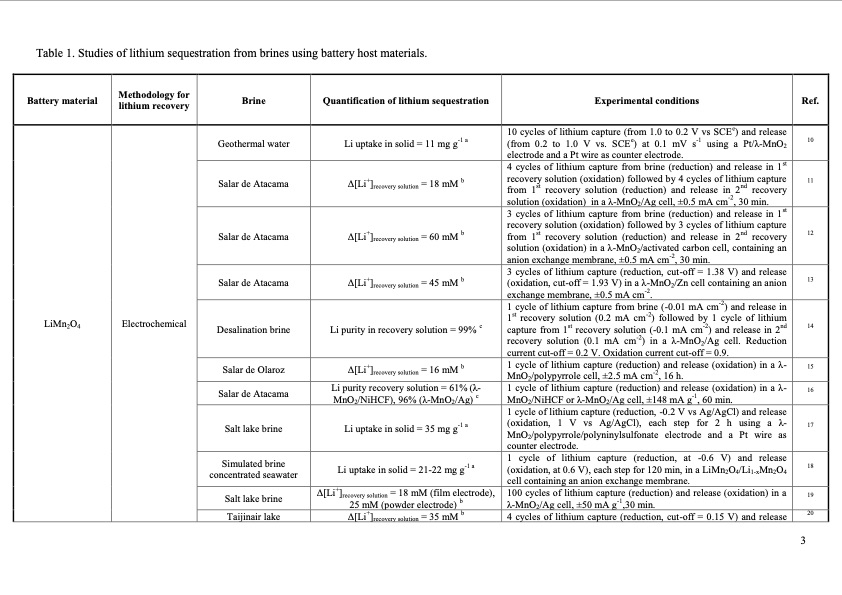

Table 1. Studies of lithium sequestration from brines using battery host materials. Battery material Methodology for lithium recovery Brine Quantification of lithium sequestration Experimental conditions 10 cycles of lithium capture (from 1.0 to 0.2 V vs SCEe) and release (from 0.2 to 1.0 V vs. SCEe) at 0.1 mV s-1 using a Pt/λ-MnO2 electrode and a Pt wire as counter electrode. Geothermal water Li uptake in solid = 11 mg g-1 a 4 cycles of lithium capture from brine (reduction) and release in 1st recovery solution (oxidation) followed by 4 cycles of lithium capture from 1st recovery solution (reduction) and release in 2nd recovery solution (oxidation) in a λ-MnO2/Ag cell, ±0.5 mA cm-2, 30 min. Salar de Atacama Δ[Li+]recovery solution = 18 mM b 3 cycles of lithium capture from brine (reduction) and release in 1st recovery solution (oxidation) followed by 3 cycles of lithium capture from 1st recovery solution (reduction) and release in 2nd recovery solution (oxidation) in a λ-MnO2/activated carbon cell, containing an anion exchange membrane, ±0.5 mA cm-2, 30 min. Salar de Atacama Δ[Li+]recovery solution = 60 mM b Salar de Atacama Δ[Li+]recovery solution = 45 mM b 3 cycles of lithium capture (reduction, cut-off = 1.38 V) and release (oxidation, cut-off = 1.93 V) in a λ-MnO2/Zn cell containing an anion exchange membrane, ±0.5 mA cm-2. 1 cycle of lithium capture from brine (-0.01 mA cm-2) and release in 1st recovery solution (0.2 mA cm-2) followed by 1 cycle of lithium capture from 1st recovery solution (-0.1 mA cm-2) and release in 2nd recovery solution (0.1 mA cm-2) in a λ-MnO2/Ag cell. Reduction current cut-off = 0.2 V. Oxidation current cut-off = 0.9. Desalination brine Li purity in recovery solution = 99% c LiMn2O4 Electrochemical Ref. 10 11 12 13 14 15 16 17 18 19 20 Salar de Olaroz Salar de Atacama Δ[Li+] recovery solution = 16 mM b 1 cycle of lithium capture (reduction) and release (oxidation) in a λ- MnO2/polypyrrole cell, ±2.5 mA cm-2, 16 h. 1 cycle of lithium capture (reduction) and release (oxidation) in a λ- MnO2/NiHCF or λ-MnO2/Ag cell, ±148 mA g-1, 60 min. 100 cycles of lithium capture (reduction) and release (oxidation) in a λ-MnO2/Ag cell, ±50 mA g-1,30 min. 4 cycles of lithium capture (reduction, cut-off = 0.15 V) and release Salt lake brine Li uptake in solid = 35 mg g-1 a 1 cycle of lithium capture (reduction, -0.2 V vs Ag/AgCl) and release (oxidation, 1 V vs Ag/AgCl), each step for 2 h using a λ- MnO2/polypyrrole/polyninylsulfonate electrode and a Pt wire as counter electrode. Simulated brine concentrated seawater Li uptake in solid = 21-22 mg g-1 a 1 cycle of lithium capture (reduction, at -0.6 V) and release (oxidation, at 0.6 V), each step for 120 min, in a LiMn2O4/Li1-xMn2O4 cell containing an anion exchange membrane. Salt lake brine Taijinair lake Li purity recovery solution = 61% (λ- MnO2/NiHCF), 96% (λ-MnO2/Ag) c Δ[Li+]recovery solution = 18 mM (film electrode), 25 mM (powder electrode) b Δ[Li+]recovery solution = 35 mM b 3PDF Image | Novel method of lithium production from brines

PDF Search Title:

Novel method of lithium production from brinesOriginal File Name Searched:

MS_v9_ref.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |