PDF Publication Title:

Text from PDF Page: 008

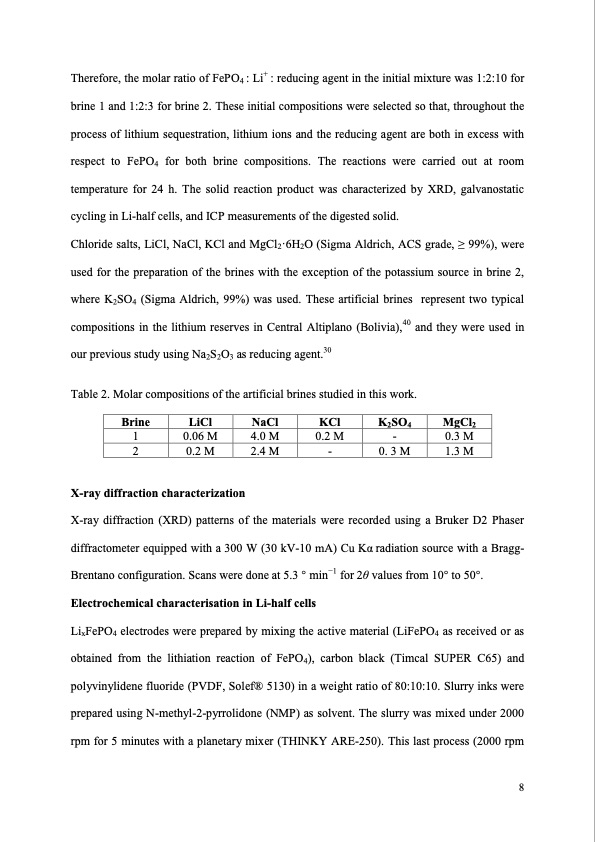

Therefore, the molar ratio of FePO4 : Li+ : reducing agent in the initial mixture was 1:2:10 for brine 1 and 1:2:3 for brine 2. These initial compositions were selected so that, throughout the process of lithium sequestration, lithium ions and the reducing agent are both in excess with respect to FePO4 for both brine compositions. The reactions were carried out at room temperature for 24 h. The solid reaction product was characterized by XRD, galvanostatic cycling in Li-half cells, and ICP measurements of the digested solid. Chloride salts, LiCl, NaCl, KCl and MgCl2·6H2O (Sigma Aldrich, ACS grade, ≥ 99%), were used for the preparation of the brines with the exception of the potassium source in brine 2, where K2SO4 (Sigma Aldrich, 99%) was used. These artificial brines represent two typical compositions in the lithium reserves in Central Altiplano (Bolivia),40 and they were used in our previous study using Na2S2O3 as reducing agent.30 Table 2. Molar compositions of the artificial brines studied in this work. Brine 1 2 LiCl 0.06 M 0.2 M NaCl 4.0 M 2.4 M KCl 0.2 M - K2SO4 - 0. 3 M MgCl2 0.3 M 1.3 M X-ray diffraction characterization X-ray diffraction (XRD) patterns of the materials were recorded using a Bruker D2 Phaser diffractometer equipped with a 300 W (30 kV-10 mA) Cu Kα radiation source with a Bragg- Brentano configuration. Scans were done at 5.3 ° min−1 for 2θ values from 10° to 50°. Electrochemical characterisation in Li-half cells LixFePO4 electrodes were prepared by mixing the active material (LiFePO4 as received or as obtained from the lithiation reaction of FePO4), carbon black (Timcal SUPER C65) and polyvinylidene fluoride (PVDF, Solef® 5130) in a weight ratio of 80:10:10. Slurry inks were prepared using N-methyl-2-pyrrolidone (NMP) as solvent. The slurry was mixed under 2000 rpm for 5 minutes with a planetary mixer (THINKY ARE-250). This last process (2000 rpm 8PDF Image | Novel method of lithium production from brines

PDF Search Title:

Novel method of lithium production from brinesOriginal File Name Searched:

MS_v9_ref.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |