PDF Publication Title:

Text from PDF Page: 006

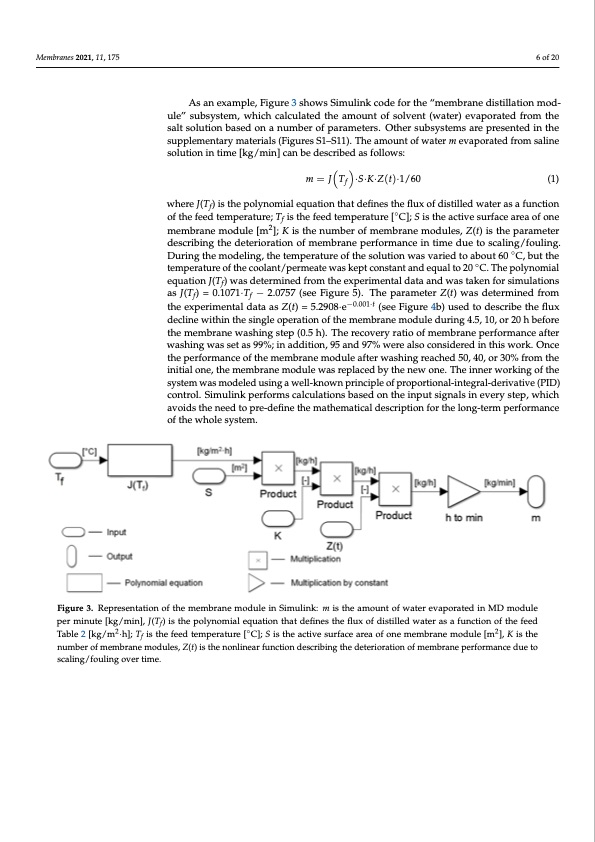

Membranes 2021, 11, 175 6 of 20 Membranes 2021, 11, 175 As an example, Figure 3 shows Simulink code for the “membrane distillation mod- ule” subsystem, which calculated the amount of solvent (water) evaporated from the salt solution based on a number of parameters. Other subsystems are presented in the supplementary materials (Figures S1–S11). The amount of water m evaporated from saline solution in time [kg/min] can be described as follows: m = JT ·S·K·Z(t)·1/60 (1) f where J(Tf) is the polynomial equation that defines the flux of distilled water as a function of the feed temperature; Tf is the feed temperature [◦C]; S is the active surface area of one membrane module [m2]; K is the number of membrane modules, Z(t) is the parameter describing the deterioration of membrane performance in time due to scaling/fouling. During the modeling, the temperature of the solution was varied to about 60 ◦C, but the temperature of the coolant/permeate was kept constant and equal to 20 ◦C. The polynomial equation J(Tf) was determined from the experimental data and was taken for simulations as J(Tf) = 0.1071·Tf − 2.0757 (see Figure 5). The parameter Z(t) was determined from the experimental data as Z(t) = 5.2908·e−0.001·t (see Figure 4b) used to describe the flux decline within the single operation of the membrane module during 4.5, 10, or 20 h before the membrane washing step (0.5 h). The recovery ratio of membrane performance after washing was set as 99%; in addition, 95 and 97% were also considered in this work. Once the performance of the membrane module after washing reached 50, 40, or 30% from the initial one, the membrane module was replaced by the new one. The inner working of the system was modeled using a well-known principle of proportional-integral-derivative (PID) 7 of 21 control. Simulink performs calculations based on the input signals in every step, which avoids the need to pre-define the mathematical description for the long-term performance of the whole system. FiFgiugurere3.3R. eRperperseesenntatatitoionoofftthemembranemodulleiinSiimulilninkk::miissttheeamoouunnttooffwaatetrerevevapaoproartaedtedininMMDDmmodoudleule pepremr mininuutete[k[kgg/m/minin],],J(JT(Tf)f)isisththeeppoolylynnoomiiallequationthatdefifineesstthheeflfuluxxooffddisitsitlilleldedwwataetrearsaasafufnucnticotnioonfothfethfeefdeed 2◦22 TaTbablele22.[hk]g;/Tmf is·ht]h;eTffeisetdhetefmeepdetreamtupreera[t°uCre];[SCi]s;Sthiestahcetiavcetivsuersfuarcfeacaeraeraeaofofoonneemembranemoodduulele[m[m],]K,Kisitshethe nunmumbbeerrof membbrraanneemmodoudleusl,eZs(,t)Zi(st)thiesntohnelineoanrlfiunnecatriofnudnecstciorinbindgesthcreibdeintegriothraetidonetoefrimoermatbioranneofpemrfeomrmbarnacneedpuertfoor- msacnalciengd/ufeoutloinsgcaolvinergt/ifmoue.ling over time. 6 5 4 3 2 1 0 membrane washing 0 50 100 150 200 250 300 350 400 450 Permeate flux, kg/m2∙h Time, min aPDF Image | Process of Lithium Recovery from Geothermal Brine

PDF Search Title:

Process of Lithium Recovery from Geothermal BrineOriginal File Name Searched:

membranes-11-00175-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |