PDF Publication Title:

Text from PDF Page: 012

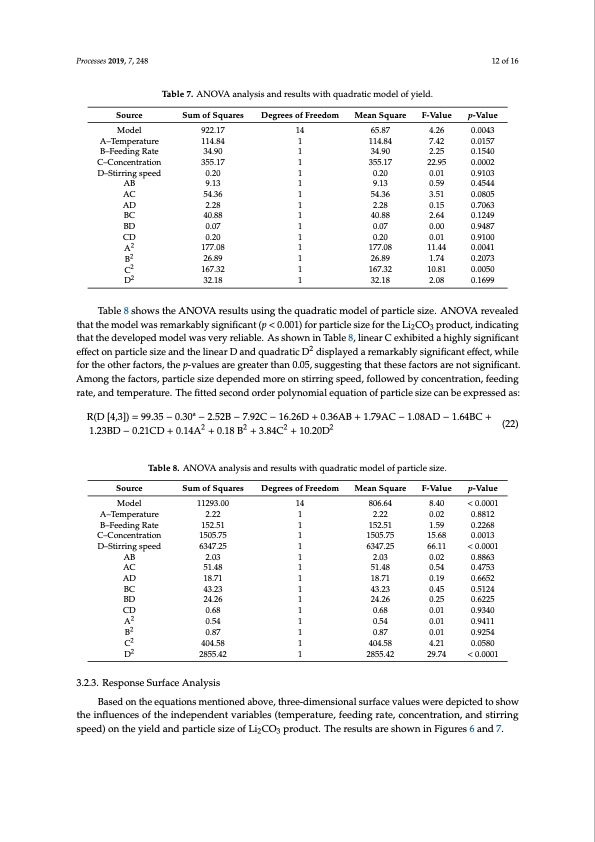

Processes 2019, 7, 248 12 of 16 Table 7. ANOVA analysis and results with quadratic model of yield. Source Model A–Temperature B–Feeding Rate C–Concentration D–Stirring speed AB AC AD BC BD CD A2 B2 C2 D2 Sum of Squares 922.17 114.84 34.90 355.17 0.20 9.13 54.36 2.28 40.88 0.07 0.20 177.08 26.89 167.32 32.18 Degrees of Freedom 14 1 1 1 1 1 1 1 1 1 1 1 1 1 Mean Square F-Value 65.87 4.26 114.84 7.42 34.90 2.25 355.17 22.95 0.20 0.01 9.13 0.59 54.36 3.51 2.28 0.15 40.88 2.64 0.07 0.00 0.20 0.01 177.08 11.44 26.89 1.74 167.32 10.81 p-Value 0.0043 0.0157 0.1540 0.0002 0.9103 0.4544 0.0805 0.7063 0.1249 0.9487 0.9100 0.0041 0.2073 0.0050 0.1699 Table 8. ANOVA analysis and results with quadratic model of particle size. 1 32.18 2.08 Table 8 shows the ANOVA results using the quadratic model of particle size. ANOVA revealed that the model was remarkably significant (p < 0.001) for particle size for the Li2CO3 product, indicating that the developed model was very reliable. As shown in Table 8, linear C exhibited a highly significant effect on particle size and the linear D and quadratic D2 displayed a remarkably significant effect, while for the other factors, the p-values are greater than 0.05, suggesting that these factors are not significant. Among the factors, particle size depended more on stirring speed, followed by concentration, feeding rate, and temperature. The fitted second order polynomial equation of particle size can be expressed as: R(D [4,3]) = 99.35 − 0.30a − 2.52B − 7.92C − 16.26D + 0.36AB + 1.79AC − 1.08AD − 1.64BC + 1.23BD − 0.21CD + 0.14A2 + 0.18 B2 + 3.84C2 + 10.20D2 (22) Source Model A–Temperature B–Feeding Rate C–Concentration D–Stirring speed AB AC AD BC BD CD A2 B2 C2 D2 Sum of Squares 11293.00 2.22 152.51 1505.75 6347.25 2.03 51.48 18.71 43.23 24.26 0.68 0.54 0.87 404.58 2855.42 Degrees of Freedom 14 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Mean Square F-Value 806.64 8.40 2.22 0.02 152.51 1.59 1505.75 15.68 6347.25 66.11 2.03 0.02 51.48 0.54 18.71 0.19 43.23 0.45 24.26 0.25 0.68 0.01 0.54 0.01 0.87 0.01 404.58 4.21 2855.42 29.74 p-Value < 0.0001 0.8812 0.2268 0.0013 < 0.0001 0.8863 0.4753 0.6652 0.5124 0.6225 0.9340 0.9411 0.9254 0.0580 < 0.0001 3.2.3. Response Surface Analysis Based on the equations mentioned above, three-dimensional surface values were depicted to show the influences of the independent variables (temperature, feeding rate, concentration, and stirring speed) on the yield and particle size of Li2CO3 product. The results are shown in Figures 6 and 7.PDF Image | Reactive Crystallization Process of Lithium Carbonate

PDF Search Title:

Reactive Crystallization Process of Lithium CarbonateOriginal File Name Searched:

processes-07-00248-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |