PDF Publication Title:

Text from PDF Page: 008

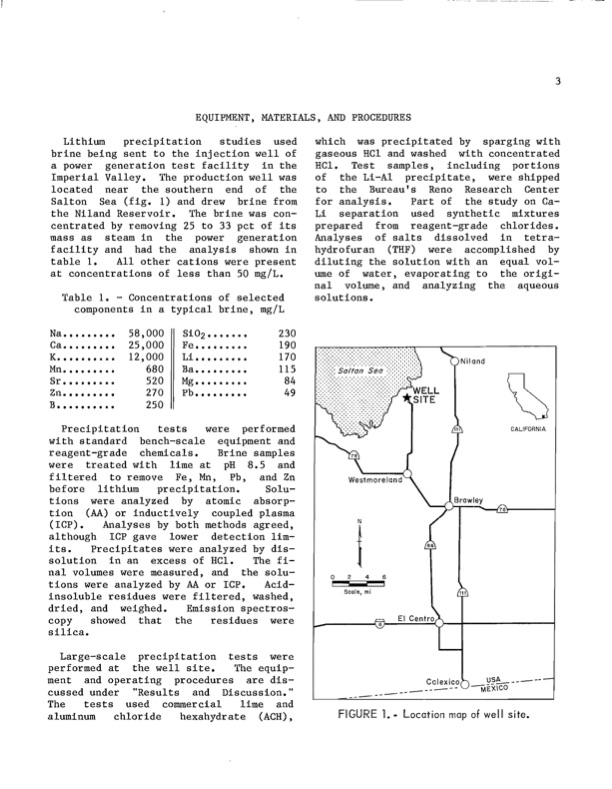

3 EQUIPMENT, MATERIALS, AND PROCEDURES Lithium precipitation studies used which was precipitated by sparging with brine being sent to the injection well of a power generation test facility in the Imperial Valley. The production well was located near the southern end of the Salton Sea (fig. 1) and drew brine from for analysis. Part of the study on Ca- the Niland Reservoir. The brine was con- Li separation used synthetic mixtures centrated by removing 25 to 33 pet of its prepared from reagent-grade chlorides. mass as steam in the power generation Analyses of salts dissolved in tetra- facility and had the analysis shown in hydrofuran (THF) were accomplished by table 1. All other cations were present diluting the solution with an equal vol- at concentrations of less than 50 mg/L. Table 1. - Concentrations of selected components in a typical brine, mg/L ume of water, evaporating to the origi- nal volume, and analyzing the aqueous solutions. Na••••••••• 58,000 Ca•• til _ • • • • • 25,000 K•••••••••• 12,000 Mn••••••••• 680 Sr ••••••.•• 520 Zn••••••••• 270 B•••••••••• 250 Si02 ••••••• 230 Fe ••••••••• 190 Li..••••••. 170 Ba••••••••• 115 Mg••••••••• 84 ph••••••••• 49 Precipitation tests were performed with standard bench-scale equipment and reagent-grade chemicals. Brine samples were treated with lime at pH 8.5 and filtered to remove Fe, Mn, Pb, and Zn before lithium precipitation. Solu- tions were analyzed by atomic absorp- tion (AA) or inductively coupled plasma (ICP). Analyses by both methods agreed, although ICP gave lower detection lim- its. Precipitates were analyzed by dis- solution in an excess of HCl. The fi- nal volumes were measured, and the solu- tions were analyzed by AA or ICP. Acid- insoluble residues were filtered, washed, dried, and weighed. Emission spectros- copy showed that the residues were silica. Large-scale precipitation tests were performed at the well site. The equip- ment and operating procedures are dis- cussed under "Results and Discussion." The tests used commercial lime and aluminum chloride hexahydrate (ACH), CALIFORNIA gaseous HCl and washed with concentrated HCI. Test samples, including portions of the Li-Al precipitate, were shipped to the Bureau's Reno Research Center o46 ii scote, mi FIGURE 1. ~ Location map of well site. y~~---- MEXICOPDF Image | Recovering Lithium Chloride From a Geothermal Brine 1984

PDF Search Title:

Recovering Lithium Chloride From a Geothermal Brine 1984Original File Name Searched:

cdc_10654_DS1.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |