PDF Publication Title:

Text from PDF Page: 009

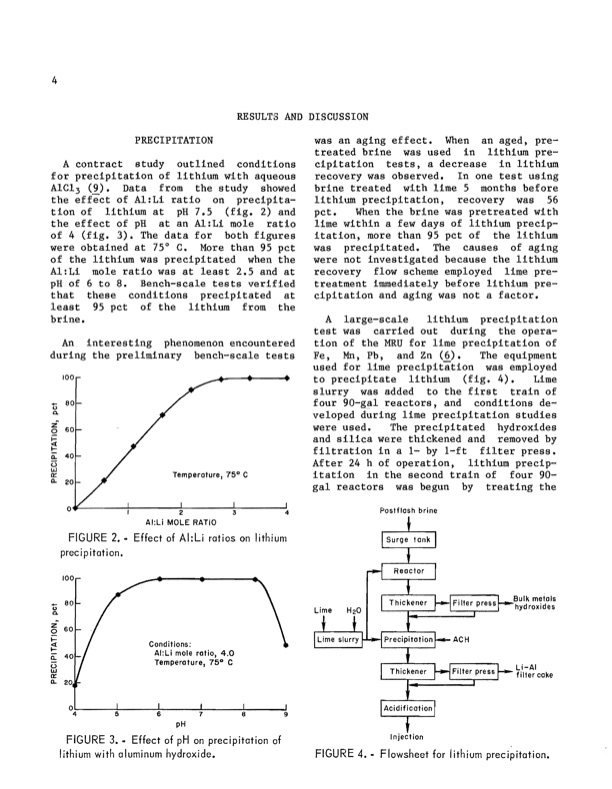

4 +- 80 0 a. Z 0 60 t= ~ a.. 40 (3 w a:: a.. 20 0 Temperature, 75° C 2 AI:Li MOLE RATIO used for lime precipitation was employed to precipitate lithium (fig. 4). Lime slurry was added to the first train of four 90-g~l reactors~ and conditions de- veloped during lime precipitation studies were used. The precipitated hydroxides and silica were thickened and removed by filtration in a 1- by I-ft filter press. After 24 h of operation, lithium precip- itation in the second train of four 90- gal reactors was begun by treating the FIGURE 2. - Effect of AI:Li ratios on lithium precipitation. 100 +- 80 o a. ~ 60 i= ~ a.. fd a:: a.. Conditions: AI:Li mole ratio, 4.0 Temperature, 75° C Bulk metals hydroxides Li-AI filler cake 2 0 ~~----~----~~----~------~----~ pH FIGURE 3. - Effect of pH on precipitation of lithium with aluminum hydroxide. Injection RESULTS AND DISCUSSION PRECIPITATION was an aging effect. When an aged, pre- treated brine was used in lithium pre- A contract study outlined conditions cipitation tests, a decrease in lithium for precipitation of lithium with aqueous recovery was observed. In one test using AlCl3 (9). Data from the study showed brine treated with lime 5 months before the effect of Al:Li ratio on precipita- lithium precipitation, recovery was 56 tion of lithium at pH 7.5 (fig. 2) and pet. When the brine was pretreated with the effect of pH at an Al:Li mole ratio of 4 (fig. 3). The data for both figures were obtained at 75° C. More than 95 pet of the lithium was precipitated when the Al:Li mole ratio was at least 2.5 and at pH of 6 to 8. Bench-scale tests verified that these conditions precipitated at least 95 pet of the lithium from the brine. lime within a few days of lithium precip- itation, more than 95 pet of the lithium was precipitated. The causes of aging were not investigated because the lithium recovery flow scheme employed lime pre- treatment immediately before lithium pre- cipitation and aging was not a factor. A large-scale lithium precipitation test was carried out during the opera- tion of the MRU for lime precipitation of An interesting phenomenon encountered during the preliminary bench-scale tests Fe, Mn, Pb, and Zn (6). The equipment Postflash brine FIGURE 4. - Flowsheet for lithium precipitation.PDF Image | Recovering Lithium Chloride From a Geothermal Brine 1984

PDF Search Title:

Recovering Lithium Chloride From a Geothermal Brine 1984Original File Name Searched:

cdc_10654_DS1.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |