PDF Publication Title:

Text from PDF Page: 011

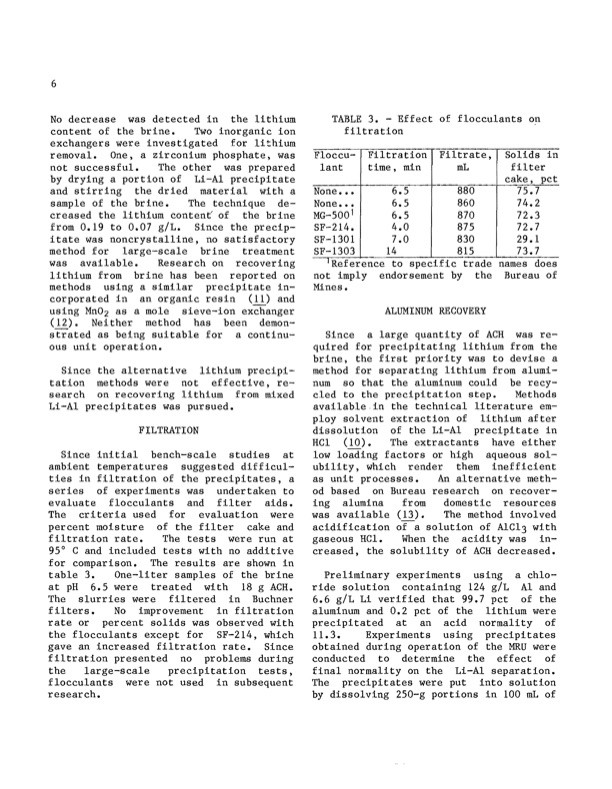

6 No decrease was detected in the lithium content of the brine. Two inorganic ion exchangers were investigated for lithium removal. One, a zirconium phosphate, was not successful. The other was prepared by drying a portion of Li-A1 precipitate and stirring the dried material with a sample of the brine. The technique de- creased the lithium content of the brine from 0.19 to 0.07 giL. Since the precip- itate was noncrystalline, no satisfactory method for large-scale brine treatment was available. Research on recovering lithium from brine has been reported on methods using a similar precipitate 1n- corporated in an organic resin (ll) and using Mn02 as a mole sieve-ion exchanger (12). Neither method has been demon- strated as being suitable for a continu- ous unit operation. Since the alternative lithium precipi- tation methods were not effective, re- search on recovering lithium from mixed Li-A1 precipitates was pursued. TABLE 3. - Effect of f10ccu1ants on filtration F10ccu- Filtration Filtrate, Solids in FIL TRA TION Since initial bench-scale studies at low loading factors or high aqueous sol- ambient temperatures suggested difficul- ties in filtration of the precipitates, a series of experiments was undertaken to evaluate f10ccu1ants and filter aids. The criteria used for evaluation were was available (11). The method involved percent moisture of the filter cake and acidification of a solution of AlC13 with filtration rate. The tests were run at gaseous HCI. When the acidity was in- 95° C and included tests with no additive for comparison. The results are shown in table 3. One-liter samples of the brine at pH 6.S were treated with 18 g ACH. The slurries were filtered in Buchner 6.6 giL Li verified that 99.7 pct of the filters. No improvement in filtration aluminum and 0.2 pet of the lithium were rate or percent solids was observed with precipitated at an acid normality of the f10ccu1ants except for SF-214, which 11.3. Experiments using precipitates gave an increased filtration rate. Since obtained during operation of the MRU were filtration presented no problems during conducted to determine the effect of the large-scale precipitation tests, final normality on the Li-A1 separation. floccu1ants were not used in subsequent The precipitates were put into solution research. by dissolving 250-g portions in 100 mL of lant None ••• None ••• MG-SOOl SF-214. SF-1301 SF-1303 time, min 6.5 6.5 6.S 4.0 7.0 mL filter cake, pct 880 ---=rS.7 860 74.2 870 72.3 875 72.7 830 29.1 815 73.7 14 I Reference to specif~c trade names does not imply endorsement by the Bureau of Mines. ALUMINUM RECOVERY Since a large quantity of ACH was re- quired for precipitating lithium from the brine, the first priority was to devise a method for separating lithium from alumi- num so that the aluminum could be recy- cled to the precipitation step. Methods avai1ab1e.in the technical literature em- ploy solvent extraction of lithium after dissolution of the Li-A1 precipitate in HC1 (lQ). The extractants have either ubility, which render them inefficient as unit processes. An alternative meth- od based on Bureau research on recover- ing alumina from domestic resources creased, the solubility of ACH decreased. Preliminary experiments using a chlo- ride solution containing 124 giL A1 andPDF Image | Recovering Lithium Chloride From a Geothermal Brine 1984

PDF Search Title:

Recovering Lithium Chloride From a Geothermal Brine 1984Original File Name Searched:

cdc_10654_DS1.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |