PDF Publication Title:

Text from PDF Page: 012

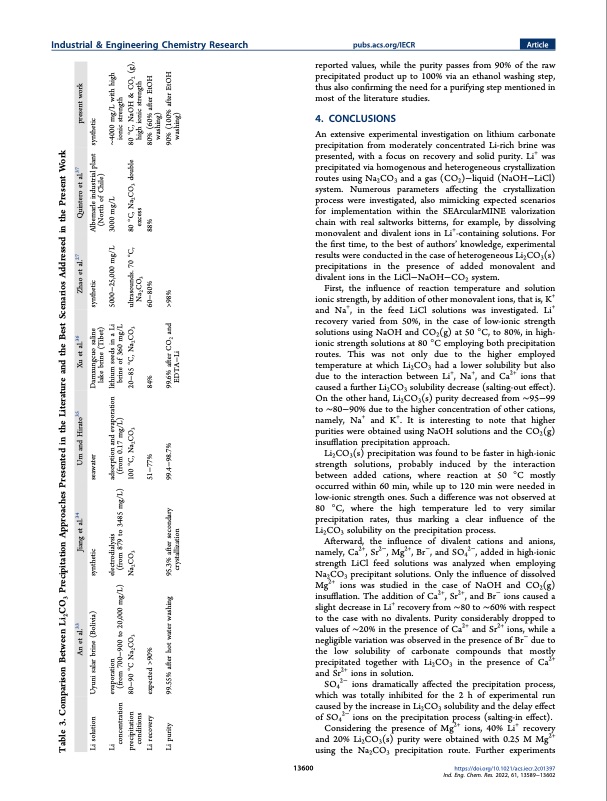

Industrial & Engineering Chemistry Research pubs.acs.org/IECR Article 13600 reported values, while the purity passes from 90% of the raw precipitated product up to 100% via an ethanol washing step, thus also confirming the need for a purifying step mentioned in most of the literature studies. 4. CONCLUSIONS An extensive experimental investigation on lithium carbonate precipitation from moderately concentrated Li-rich brine was presented, with a focus on recovery and solid purity. Li+ was precipitated via homogenous and heterogeneous crystallization routes using Na2CO3 and a gas (CO2)−liquid (NaOH−LiCl) system. Numerous parameters affecting the crystallization process were investigated, also mimicking expected scenarios for implementation within the SEArcularMINE valorization chain with real saltworks bitterns, for example, by dissolving monovalent and divalent ions in Li+-containing solutions. For the first time, to the best of authors’ knowledge, experimental results were conducted in the case of heterogeneous Li2CO3(s) precipitations in the presence of added monovalent and divalent ions in the LiCl−NaOH−CO2 system. First, the influence of reaction temperature and solution ionic strength, by addition of other monovalent ions, that is, K+ and Na+, in the feed LiCl solutions was investigated. Li+ recovery varied from 50%, in the case of low-ionic strength solutions using NaOH and CO2(g) at 50 °C, to 80%, in high- ionic strength solutions at 80 °C employing both precipitation routes. This was not only due to the higher employed temperature at which Li2CO3 had a lower solubility but also due to the interaction between Li+, Na+, and Ca2+ ions that caused a further Li2CO3 solubility decrease (salting-out effect). On the other hand, Li2CO3(s) purity decreased from ∼95−99 to ∼80−90% due to the higher concentration of other cations, namely, Na+ and K+. It is interesting to note that higher purities were obtained using NaOH solutions and the CO2(g) insufflation precipitation approach. Li2CO3(s) precipitation was found to be faster in high-ionic strength solutions, probably induced by the interaction between added cations, where reaction at 50 °C mostly occurred within 60 min, while up to 120 min were needed in low-ionic strength ones. Such a difference was not observed at 80 °C, where the high temperature led to very similar precipitation rates, thus marking a clear influence of the Li2CO3 solubility on the precipitation process. Afterward, the influence of divalent cations and anions, namely, Ca2+, Sr2−, Mg2+, Br−, and SO42−, added in high-ionic strength LiCl feed solutions was analyzed when employing Na2CO3 precipitant solutions. Only the influence of dissolved Mg2+ ions was studied in the case of NaOH and CO2(g) insufflation. The addition of Ca2+, Sr2+, and Br− ions caused a slight decrease in Li+ recovery from ∼80 to ∼60% with respect to the case with no divalents. Purity considerably dropped to values of ∼20% in the presence of Ca2+ and Sr2+ ions, while a negligible variation was observed in the presence of Br− due to the low solubility of carbonate compounds that mostly precipitated together with Li2CO3 in the presence of Ca2+ and Sr2+ ions in solution. SO42− ions dramatically affected the precipitation process, which was totally inhibited for the 2 h of experimental run caused by the increase in Li2CO3 solubility and the delay effect of SO42− ions on the precipitation process (salting-in effect). Considering the presence of Mg2+ ions, 40% Li+ recovery and 20% Li2CO3(s) purity were obtained with 0.25 M Mg2+ using the Na2CO3 precipitation route. Further experiments https://doi.org/10.1021/acs.iecr.2c01397 Ind. Eng. Chem. Res. 2022, 61, 13589−13602 Table 3. Comparison Between Li2CO3 Precipitation Approaches Presented in the Literature and the Best Scenarios Addressed in the Present Work Li solution An et al.33 Uyuni salar brine (Bolivia) Jiang et al.34 synthetic Um and Hirato35 seawater Xu et al.36 Damxungcuo saline Zhao et al.27 synthetic Quintero et al.37 present work Albemarle industrial plant synthetic Li concentration evaporation (from 700−900 to 20,000 mg/L) electrodialysis (from 879 to 3485 mg/L) adsorption and evaporation (from 0.17 mg/L) lithium seeds in a Li brine of 360 mg/L 5000−25,000 mg/L ultrasounds. 70 °C, ∼4000 mg/L with high ionic strength precipitation conditions 80−90 °C Na2CO3 expected >90% 99.55% after hot water washing Na2CO3 100 °C, Na2CO3 51−77% 99.4−98.7% 20−85 °C, Na2CO3 Na2CO3 60−80% 80 °C, Na2CO3 double excess 80 °C, NaOH & CO2 (g), high ionic strength Li recovery Li purity 84% 88% 80% (60% after EtOH washing) 95.3% after secondary crystallization 99.6% after CO2 and EDTA−Li >98% 90% (100% after EtOH washing) lake brine (Tibet) (North of Chile) 3000 mg/LPDF Image | Recovery of Lithium Carbonate from Dilute Li Rich Brine

PDF Search Title:

Recovery of Lithium Carbonate from Dilute Li Rich BrineOriginal File Name Searched:

acs.iecr.2c01397.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |