PDF Publication Title:

Text from PDF Page: 011

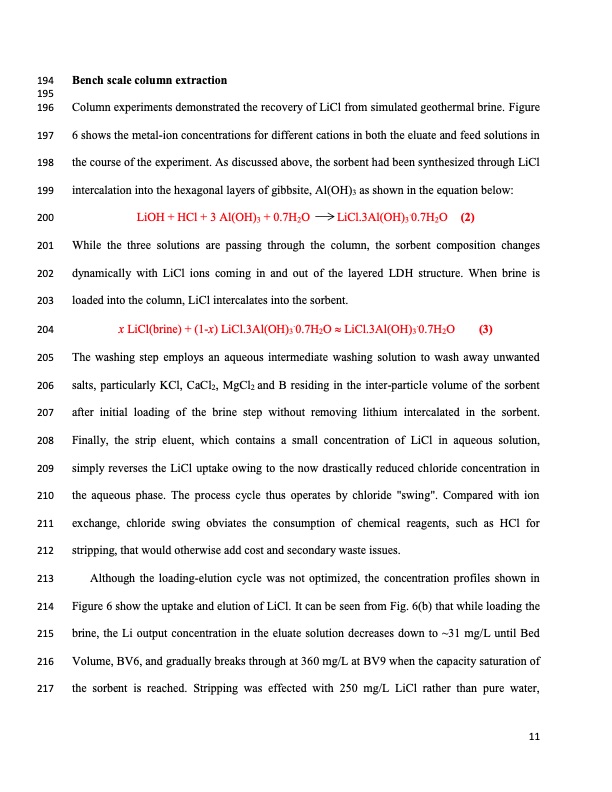

194 Bench scale column extraction 195 196 Column experiments demonstrated the recovery of LiCl from simulated geothermal brine. Figure 197 6 shows the metal-ion concentrations for different cations in both the eluate and feed solutions in 198 the course of the experiment. As discussed above, the sorbent had been synthesized through LiCl 199 intercalation into the hexagonal layers of gibbsite, Al(OH)3 as shown in the equation below: 200 LiOH + HCl + 3 Al(OH)3 + 0.7H2O LiCl.3Al(OH)3.0.7H2O (2) 201 While the three solutions are passing through the column, the sorbent composition changes 202 dynamically with LiCl ions coming in and out of the layered LDH structure. When brine is 203 loaded into the column, LiCl intercalates into the sorbent. 204 x LiCl(brine) + (1-x) LiCl.3Al(OH)3.0.7H2O LiCl.3Al(OH)3.0.7H2O (3) 205 The washing step employs an aqueous intermediate washing solution to wash away unwanted 206 salts, particularly KCl, CaCl2, MgCl2 and B residing in the inter-particle volume of the sorbent 207 after initial loading of the brine step without removing lithium intercalated in the sorbent. 208 Finally, the strip eluent, which contains a small concentration of LiCl in aqueous solution, 209 simply reverses the LiCl uptake owing to the now drastically reduced chloride concentration in 210 the aqueous phase. The process cycle thus operates by chloride "swing". Compared with ion 211 exchange, chloride swing obviates the consumption of chemical reagents, such as HCl for 212 stripping, that would otherwise add cost and secondary waste issues. 213 Although the loading-elution cycle was not optimized, the concentration profiles shown in 214 Figure 6 show the uptake and elution of LiCl. It can be seen from Fig. 6(b) that while loading the 215 brine, the Li output concentration in the eluate solution decreases down to ~31 mg/L until Bed 216 Volume, BV6, and gradually breaks through at 360 mg/L at BV9 when the capacity saturation of 217 the sorbent is reached. Stripping was effected with 250 mg/L LiCl rather than pure water, 11PDF Image | Recovery of Lithium from Geothermal Brine Li AL

PDF Search Title:

Recovery of Lithium from Geothermal Brine Li ALOriginal File Name Searched:

1424451.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |