PDF Publication Title:

Text from PDF Page: 005

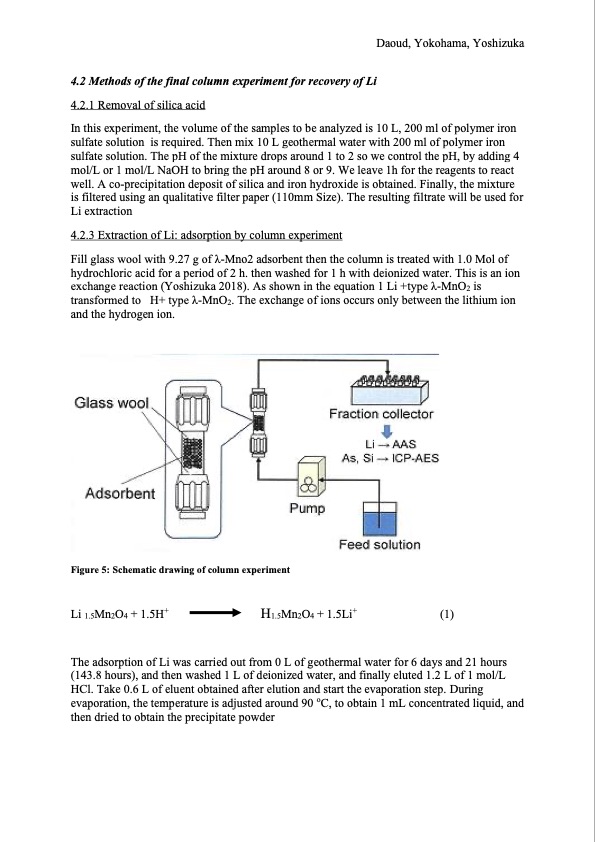

4.2 Methods of the final column experiment for recovery of Li 4.2.1 Removal of silica acid is filtered using an qualitative filter paper (110mm Size). Li extraction 4.2.3 Extraction of Li: adsorption by column experiment Finally, the mixture Daoud, Yokohama, Yoshizuka In this experiment, the volume of the samples to be analyzed is 10 L, 200 ml of polymer iron sulfate solution is required. Then mix 10 L geothermal water with 200 ml of polymer iron sulfate solution. The pH of the mixture drops around 1 to 2 so we control the pH, by adding 4 mol/L or 1 mol/L NaOH to bring the pH around 8 or 9. We leave 1h for the reagents to react well. A co-precipitation deposit of silica and iron hydroxide is obtained. The resulting filtrate will be used for Fill glass wool with 9.27 g of λ-Mno2 adsorbent then the column is treated with 1.0 Mol of hydrochloric acid for a period of 2 h. then washed for 1 h with deionized water. This is an ion exchange reaction (Yoshizuka 2018). As shown in the equation 1 Li +type λ-MnO2 is transformed to H+ type λ-MnO2. The exchange of ions occurs only between the lithium ion and the hydrogen ion. Figure 5: Schematic drawing of column experiment Li 1.5Mn2O4 + 1.5H+ H1.5Mn2O4 + 1.5Li+ (1) The adsorption of Li was carried out from 0 L of geothermal water for 6 days and 21 hours (143.8 hours), and then washed 1 L of deionized water, and finally eluted 1.2 L of 1 mol/L HCl. Take 0.6 L of eluent obtained after elution and start the evaporation step. During evaporation, the temperature is adjusted around 90 oC, to obtain 1 mL concentrated liquid, and then dried to obtain the precipitate powderPDF Image | Recovery of Lithium from Geothermal Water

PDF Search Title:

Recovery of Lithium from Geothermal WaterOriginal File Name Searched:

Daoud, Yoshizuka - 2020 - A Study on Recovery of Lithium from Geothermal Water and Study of Assal geothermal field.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |