PDF Publication Title:

Text from PDF Page: 006

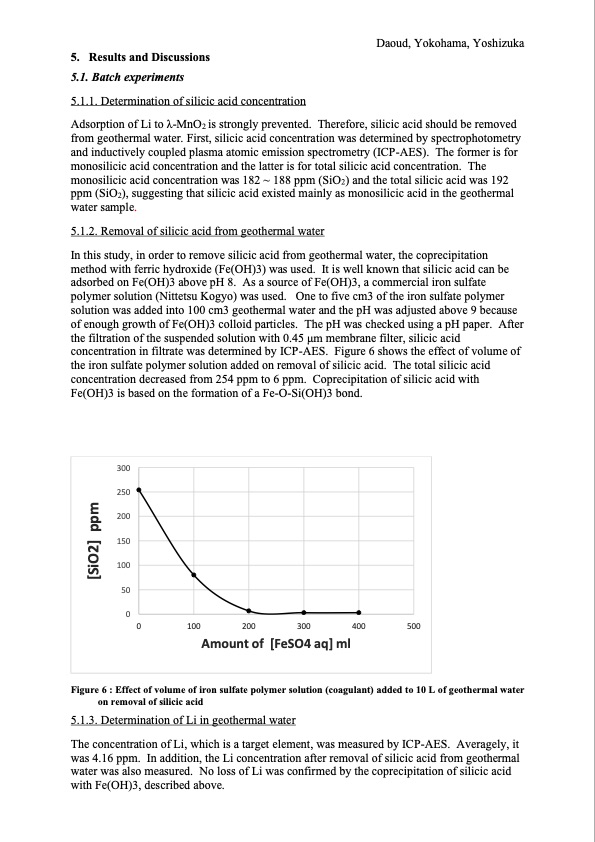

5. Results and Discussions 5.1. Batch experiments 5.1.1. Determination of silicic acid concentration Adsorption of Li to λ-MnO2 is strongly prevented. Therefore, silicic acid should be removed from geothermal water. First, silicic acid concentration was determined by spectrophotometry and inductively coupled plasma atomic emission spectrometry (ICP-AES). The former is for monosilicic acid concentration and the latter is for total silicic acid concentration. The monosilicic acid concentration was 182 ~ 188 ppm (SiO2) and the total silicic acid was 192 ppm (SiO2), suggesting that silicic acid existed mainly as monosilicic acid in the geothermal water sample. 5.1.2. Removal of silicic acid from geothermal water In this study, in order to remove silicic acid from geothermal water, the coprecipitation method with ferric hydroxide (Fe(OH)3) was used. It is well known that silicic acid can be adsorbed on Fe(OH)3 above pH 8. As a source of Fe(OH)3, a commercial iron sulfate polymer solution (Nittetsu Kogyo) was used. One to five cm3 of the iron sulfate polymer solution was added into 100 cm3 geothermal water and the pH was adjusted above 9 because of enough growth of Fe(OH)3 colloid particles. The pH was checked using a pH paper. After the filtration of the suspended solution with 0.45 μm membrane filter, silicic acid concentration in filtrate was determined by ICP-AES. Figure 6 shows the effect of volume of the iron sulfate polymer solution added on removal of silicic acid. The total silicic acid concentration decreased from 254 ppm to 6 ppm. Coprecipitation of silicic acid with Fe(OH)3 is based on the formation of a Fe-O-Si(OH)3 bond. Daoud, Yokohama, Yoshizuka 300 250 200 150 100 50 0 0 100 200 300 400 500 Amount of [FeSO4 aq] ml Figure 6 : Effect of volume of iron sulfate polymer solution (coagulant) added to 10 L of geothermal water on removal of silicic acid 5.1.3. Determination of Li in geothermal water The concentration of Li, which is a target element, was measured by ICP-AES. Averagely, it was 4.16 ppm. In addition, the Li concentration after removal of silicic acid from geothermal water was also measured. No loss of Li was confirmed by the coprecipitation of silicic acid with Fe(OH)3, described above. [SiO2] ppmPDF Image | Recovery of Lithium from Geothermal Water

PDF Search Title:

Recovery of Lithium from Geothermal WaterOriginal File Name Searched:

Daoud, Yoshizuka - 2020 - A Study on Recovery of Lithium from Geothermal Water and Study of Assal geothermal field.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |