PDF Publication Title:

Text from PDF Page: 009

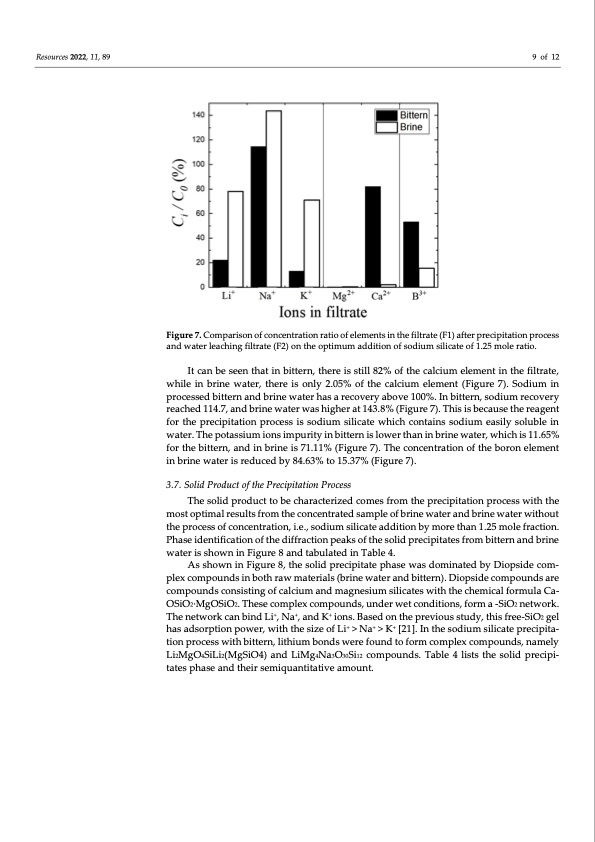

Resources 2022, 11, 89 9 of 12 Figure 7. Comparison of concentration ratio of elements in the filtrate (F1) after precipitation process and water leaching filtrate (F2) on the optimum addition of sodium silicate of 1.25 mole ratio. It can be seen that in bittern, there is still 82% of the calcium element in the filtrate, while in brine water, there is only 2.05% of the calcium element (Figure 7). Sodium in processed bittern and brine water has a recovery above 100%. In bittern, sodium recovery reached 114.7, and brine water was higher at 143.8% (Figure 7). This is because the reagent for the precipitation process is sodium silicate which contains sodium easily soluble in water. The potassium ions impurity in bittern is lower than in brine water, which is 11.65% for the bittern, and in brine is 71.11% (Figure 7). The concentration of the boron element in brine water is reduced by 84.63% to 15.37% (Figure 7). 3.7. Solid Product of the Precipitation Process The solid product to be characterized comes from the precipitation process with the most optimal results from the concentrated sample of brine water and brine water without the process of concentration, i.e., sodium silicate addition by more than 1.25 mole fraction. Phase identification of the diffraction peaks of the solid precipitates from bittern and brine water is shown in Figure 8 and tabulated in Table 4. As shown in Figure 8, the solid precipitate phase was dominated by Diopside com- plex compounds in both raw materials (brine water and bittern). Diopside compounds are compounds consisting of calcium and magnesium silicates with the chemical formula Ca- OSiO2·MgOSiO2. These complex compounds, under wet conditions, form a -SiO2 network. The network can bind Li+, Na+, and K+ ions. Based on the previous study, this free-SiO2 gel has adsorption power, with the size of Li+ > Na+ > K+ [21]. In the sodium silicate precipita- tion process with bittern, lithium bonds were found to form complex compounds, namely Li2MgO4SiLi2(MgSiO4) and LiMg4Na3O30Si12 compounds. Table 4 lists the solid precipi- tates phase and their semiquantitative amount.PDF Image | Separation of Magnesium and Lithium from Brine Water

PDF Search Title:

Separation of Magnesium and Lithium from Brine WaterOriginal File Name Searched:

resources-11-00089.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |