PDF Publication Title:

Text from PDF Page: 003

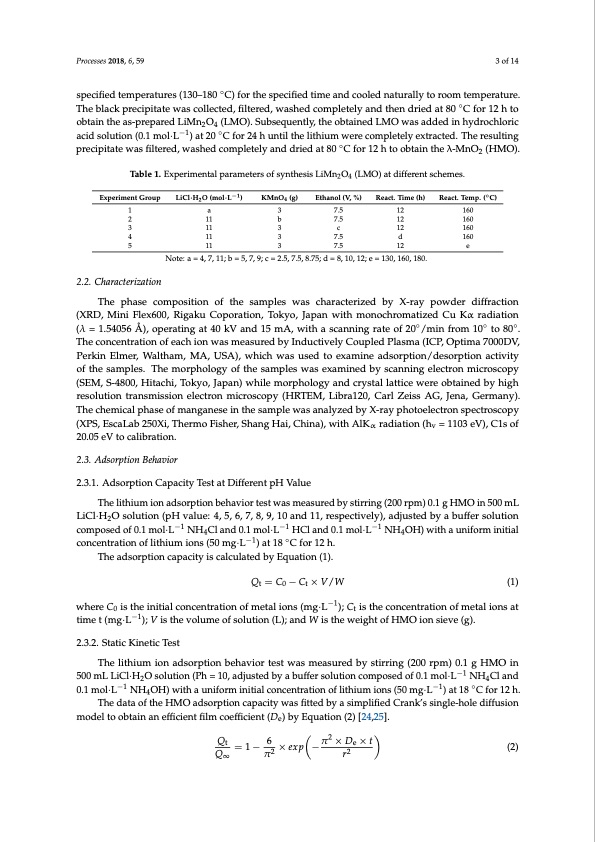

Processes 2018, 6, 59 3 of 14 specified temperatures (130–180 ◦C) for the specified time and cooled naturally to room temperature. The black precipitate was collected, filtered, washed completely and then dried at 80 ◦C for 12 h to obtain the as-prepared LiMn2O4 (LMO). Subsequently, the obtained LMO was added in hydrochloric acid solution (0.1 mol·L−1) at 20 ◦C for 24 h until the lithium were completely extracted. The resulting precipitate was filtered, washed completely and dried at 80 ◦C for 12 h to obtain the λ-MnO2 (HMO). Table 1. Experimental parameters of synthesis LiMn2O4 (LMO) at different schemes. Experiment Group LiCl·H2O (mol·L−1) KMnO4 (g) Ethanol (V, %) React. Time (h) React. Temp. (◦C) 1 a 3 7.5 12 160 2 11 b 7.5 12 160 3 11 3 c 12 160 4 11 3 7.5 d 160 5 11 3 7.5 12 e Note: a=4,7,11;b=5,7,9;c=2.5,7.5,8.75;d=8,10,12;e=130,160,180. 2.2. Characterization The phase composition of the samples was characterized by X-ray powder diffraction (XRD, Mini Flex600, Rigaku Coporation, Tokyo, Japan with monochromatized Cu Kα radiation (λ = 1.54056 Å), operating at 40 kV and 15 mA, with a scanning rate of 20◦/min from 10◦ to 80◦. The concentration of each ion was measured by Inductively Coupled Plasma (ICP, Optima 7000DV, Perkin Elmer, Waltham, MA, USA), which was used to examine adsorption/desorption activity of the samples. The morphology of the samples was examined by scanning electron microscopy (SEM, S-4800, Hitachi, Tokyo, Japan) while morphology and crystal lattice were obtained by high resolution transmission electron microscopy (HRTEM, Libra120, Carl Zeiss AG, Jena, Germany). The chemical phase of manganese in the sample was analyzed by X-ray photoelectron spectroscopy (XPS, EscaLab 250Xi, Thermo Fisher, Shang Hai, China), with AlKα radiation (hv = 1103 eV), C1s of 20.05 eV to calibration. 2.3. Adsorption Behavior 2.3.1. Adsorption Capacity Test at Different pH Value The lithium ion adsorption behavior test was measured by stirring (200 rpm) 0.1 g HMO in 500 mL LiCl·H2O solution (pH value: 4, 5, 6, 7, 8, 9, 10 and 11, respectively), adjusted by a buffer solution composed of 0.1 mol·L−1 NH4Cl and 0.1 mol·L−1 HCl and 0.1 mol·L−1 NH4OH) with a uniform initial concentration of lithium ions (50 mg·L−1) at 18 ◦C for 12 h. The adsorption capacity is calculated by Equation (1). Qt = C0 − Ct × V/W (1) where C0 is the initial concentration of metal ions (mg·L−1); Ct is the concentration of metal ions at time t (mg·L−1); V is the volume of solution (L); and W is the weight of HMO ion sieve (g). 2.3.2. Static Kinetic Test The lithium ion adsorption behavior test was measured by stirring (200 rpm) 0.1 g HMO in 500 mL LiCl·H2O solution (Ph = 10, adjusted by a buffer solution composed of 0.1 mol·L−1 NH4Cl and 0.1 mol·L−1 NH4OH) with a uniform initial concentration of lithium ions (50 mg·L−1) at 18 ◦C for 12 h. The data of the HMO adsorption capacity was fitted by a simplified Crank’s single-hole diffusion model to obtain an efficient film coefficient (De) by Equation (2) [24,25]. Qt 6 π2×De×t =1− 2×exp − 2 (2) Q∞ π rPDF Image | Sieves for Highly Selective Li Adsorption

PDF Search Title:

Sieves for Highly Selective Li AdsorptionOriginal File Name Searched:

processes-06-00059-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |