PDF Publication Title:

Text from PDF Page: 002

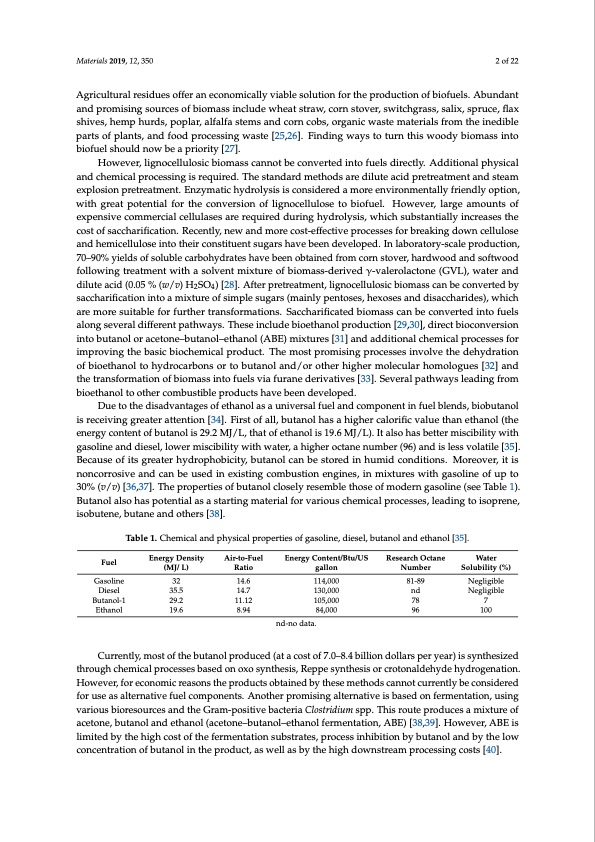

Materials 2019, 12, 350 2 of 22 Agricultural residues offer an economically viable solution for the production of biofuels. Abundant and promising sources of biomass include wheat straw, corn stover, switchgrass, salix, spruce, flax shives, hemp hurds, poplar, alfalfa stems and corn cobs, organic waste materials from the inedible parts of plants, and food processing waste [25,26]. Finding ways to turn this woody biomass into biofuel should now be a priority [27]. However, lignocellulosic biomass cannot be converted into fuels directly. Additional physical and chemical processing is required. The standard methods are dilute acid pretreatment and steam explosion pretreatment. Enzymatic hydrolysis is considered a more environmentally friendly option, with great potential for the conversion of lignocellulose to biofuel. However, large amounts of expensive commercial cellulases are required during hydrolysis, which substantially increases the cost of saccharification. Recently, new and more cost-effective processes for breaking down cellulose and hemicellulose into their constituent sugars have been developed. In laboratory-scale production, 70–90% yields of soluble carbohydrates have been obtained from corn stover, hardwood and softwood following treatment with a solvent mixture of biomass-derived γ-valerolactone (GVL), water and dilute acid (0.05 % (w/v) H2SO4) [28]. After pretreatment, lignocellulosic biomass can be converted by saccharification into a mixture of simple sugars (mainly pentoses, hexoses and disaccharides), which are more suitable for further transformations. Saccharificated biomass can be converted into fuels along several different pathways. These include bioethanol production [29,30], direct bioconversion into butanol or acetone–butanol–ethanol (ABE) mixtures [31] and additional chemical processes for improving the basic biochemical product. The most promising processes involve the dehydration of bioethanol to hydrocarbons or to butanol and/or other higher molecular homologues [32] and the transformation of biomass into fuels via furane derivatives [33]. Several pathways leading from bioethanol to other combustible products have been developed. Due to the disadvantages of ethanol as a universal fuel and component in fuel blends, biobutanol is receiving greater attention [34]. First of all, butanol has a higher calorific value than ethanol (the energy content of butanol is 29.2 MJ/L, that of ethanol is 19.6 MJ/L). It also has better miscibility with gasoline and diesel, lower miscibility with water, a higher octane number (96) and is less volatile [35]. Because of its greater hydrophobicity, butanol can be stored in humid conditions. Moreover, it is noncorrosive and can be used in existing combustion engines, in mixtures with gasoline of up to 30% (v/v) [36,37]. The properties of butanol closely resemble those of modern gasoline (see Table 1). Butanol also has potential as a starting material for various chemical processes, leading to isoprene, isobutene, butane and others [38]. Table 1. Chemical and physical properties of gasoline, diesel, butanol and ethanol [35]. Fuel Gasoline Diesel Butanol-1 Ethanol Energy Density Air-to-Fuel (MJ/ L) Ratio 32 14.6 35.5 14.7 29.2 11.12 19.6 8.94 Energy Content/Btu/US gallon 114,000 130,000 105,000 84,000 nd-no data. Research Octane Number 81-89 nd 78 96 Water Solubility (%) Negligible Negligible 7 100 Currently, most of the butanol produced (at a cost of 7.0–8.4 billion dollars per year) is synthesized through chemical processes based on oxo synthesis, Reppe synthesis or crotonaldehyde hydrogenation. However, for economic reasons the products obtained by these methods cannot currently be considered for use as alternative fuel components. Another promising alternative is based on fermentation, using various bioresources and the Gram-positive bacteria Clostridium spp. This route produces a mixture of acetone, butanol and ethanol (acetone–butanol–ethanol fermentation, ABE) [38,39]. However, ABE is limited by the high cost of the fermentation substrates, process inhibition by butanol and by the low concentration of butanol in the product, as well as by the high downstream processing costs [40].PDF Image | Butanol Synthesis Routes for Biofuel Production

PDF Search Title:

Butanol Synthesis Routes for Biofuel ProductionOriginal File Name Searched:

materials-12-00350.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |