PDF Publication Title:

Text from PDF Page: 015

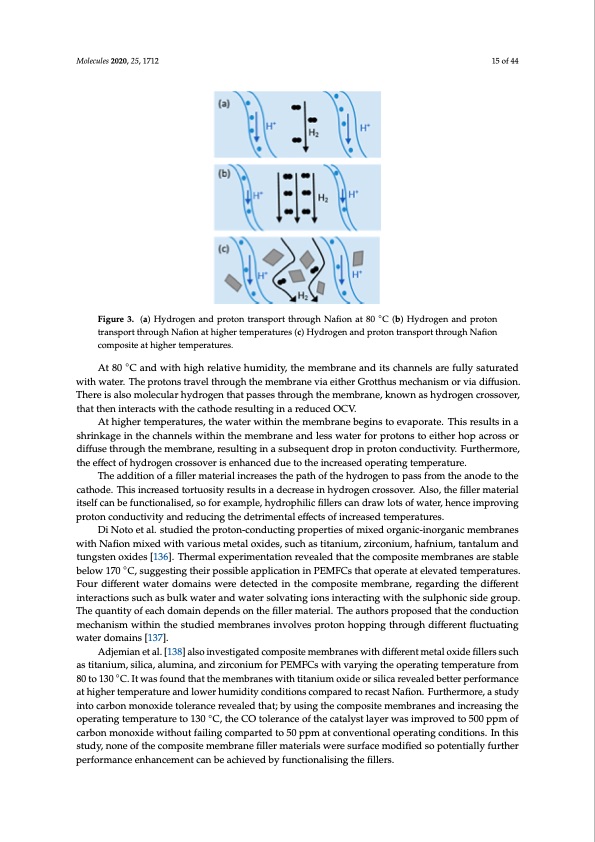

explanation of their suitability is due to their high thermal stability, mechanical strength, and water-absorbing nature. Therefore, the main aim of introducing fillers into the polymer membrane is to enhance its properties and enable its operation at elevated temperatures and/or low relative humidities. Figure 3 illustrates the change in proton conductivity and hydrogen crossover with the cMhoalencuglesi2n02o0p, 2e5r,a1t7i1n2g conditions to higher temperatures and lower relative humidities (Figure 3b1)5aonf 4d4 the incorporation of fillers (Figure 3c). Figure 3. (a) Hydrogen and proton transport through Nafion at 80 °◦C (b) Hydrogen and proton Figure 3. (a) Hydrogen and proton transport through Nafion at 80 C (b) Hydrogen and proton transport through Nafion at higher temperatures (c) Hydrogen and proton transport through Nafion transport through Nafion at higher temperatures (c) Hydrogen and proton transport through Nafion composite at higher temperatures. composite at higher temperatures. ◦ At higher temperatures,, the water within the membrane begins to evaporate. Thiis resullts in a shrinkage in the channells wiithiin the membrane and lless watter for protons to either hop across or diffffuse through the membrane, resulting in a subsequentt drop iin proton conducttiiviitty. Furrttherrmorre,, the effffect of hydrogen crossover is enhanced due to the increased operating temperature.. The addition of a ffiiller material increases the path of the hydrogen to pass from the anode to the cathode. Thisininccrereaaseseddtotroturtousoitsyityresruelstuslitns aindeacredaescereinasheyidnrohgyednrcorgoesnsovcreor.ssAolvsoer,.thAelfisoll,erthmeatfeilrliearl mitsaetlefrcianl ibtselffucnacntiobneafluisnecdt,iosnoafloisredx,asmopfoler,ehxyadmroplhe,ilhicyfidlrloeprshcilainc fdilrlaewrslcoatns odfrawwatleor,tshoenfcweaitmerp,rhoevninceg ipmroptronvicnogndpuroctoivnitcyoanndducretidvuitcyinagndthreedeutcriinmgetnhtealdefftreicmtseonftainl ecrffeeacstesdotfeimncpreraasteudretes.mperatures. Di Noto et al. ssttudiiedttheprrotton--conducttiingproperttiiesoffmiixedorganic-inorganic membranes with Naffiion mixed with various metal oxides, such as titanium, zirconium, hafnium, tantalum and Adjemian et al. [138] also investigated composite membranes with different metal oxide fillers such as titanium, silica, alumina, and zirconium for PEMFCs with varying the operating temperature from 80 to 130 ◦C. It was found that the membranes with titanium oxide or silica revealed better performance at higher temperature and lower humidity conditions compared to recast Nafion. Furthermore, a study into carbon monoxide tolerance revealed that; by using the composite membranes and increasing the operating temperature to 130 ◦C, the CO tolerance of the catalyst layer was improved to 500 ppm of carbon monoxide without failing comparted to 50 ppm at conventional operating conditions. In this study, none of the composite membrane filler materials were surface modified so potentially further performance enhancement can be achieved by functionalising the fillers. At 80 oC and wiith high relative humiidiitty, the membrane and its channels are fully saturated with waatteerr..TThheeprportontosntsratvrealvtehlrotuhgrohutghhe mtheemmbreamnebvraianeitvhiear GeirthotetrhuGsrmotethchuasnimsmecohranvisamdiffoursivoina. dTihffeuresiiosna.lTsohemreoliescaulslaormhyodlercougleanr hthyadtrpogasesnesthtahtropuasgshesthtehrmouemghbtrhaenem, kemnobwrannaes, khnyodwrongaens hcyrodsrsogvenr, cthroaststohveenr,inthteartatchtesnwiinthtetrhaectcsawthiothdethrescualtthinodgeinreasureltdinugceidnOaCreVd.ucedOCV. tungsten oxides [136]. Thermall experiimenttattiion revealled thatt the composiite membranes are stable ◦ below117700C°,Cs,ugsguegsgtiensgtitnhgeirthpeoisrsibploesaspibplleicatpiopnliicnatPioEnMFinCsPthEaMtoFpCesratehateolepveartaetdeteamtpelreavtautreds. tFeomupredraifftueresn.tFwouatredridffoemreanitnws awtereddoemteacintesdwinerethdeecteocmtepdosinitethmeecmombrpaonseit,eremgeamrdbinragnteh,eredgiaffredrienngt tihnetedraifcfteiroenst sinutcehracstibounlskswucahtearsabnudlkwwataetrersoalnvdatwinagteironsoslivnatteirnagctiiongs winitehrathcteinsgulwphitohntihcessiduelpghronuipc. sTihdeqguroanutpit.yTohfeeqauchandtoitmyaoifnedaecphednodmsoaninthdepfiellnedrsmoantetrhiael.fiTllheeramuathteorrisalp.rTohpeosaeudththoarsttphreocponsdeducthioant tmhechcoandisumctiwonithminetcheanstiusmdiewd imtheinmbthraenesstuidniveodlvmesepmrbortoanehsoipnpvionlgvetshropurogthondiffheorpepnitnflgutchturoautignhg dwiaffterednot mfluacintusa[t1i3n7g].water domains [137].PDF Image | Composite Polymers for Electrolyte Membrane Technologies

PDF Search Title:

Composite Polymers for Electrolyte Membrane TechnologiesOriginal File Name Searched:

molecules-25-01712.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |