PDF Publication Title:

Text from PDF Page: 025

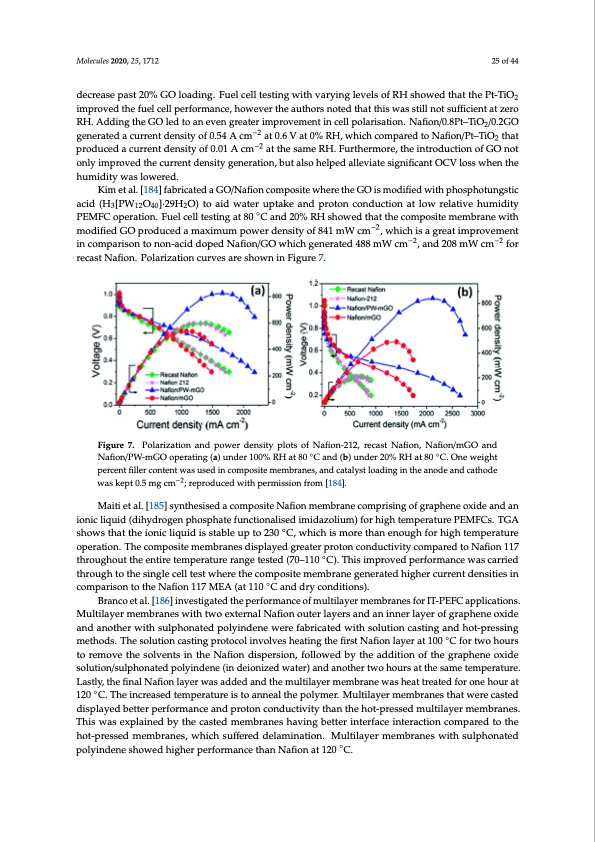

performance dropped with too much silica at low RH, which the authors explain is possibly due to the filler blocking the ionic pathways. Filler optimisation was concluded by the authors, as increases in Pt-G loading also resulted in a drop in performance. Yang et al. [183] fabricated a composite membrane with platinum deposited on titania, which is Mthoelenculiensc2o02r0p,o2r5a, 1t7e1d2 with graphene oxide into a Nafion polymer matrix. The composite memb25raonf e44s displayed a better IEC than recast Nafion, with increased until 20% GO is reached, where the IEC began to decrease beyond that. The proton conductivity followed a similar trend to the IEC, which decrease past 20% GO loading. Fuel cell testing with varying levels of RH showed that the Pt-TiO2 also decrease past 20% GO loading. Fuel cell testing with varying levels of RH showed that the improved the fuel cell performance, however the authors noted that this was still not sufficient at zero Pt-TiO2 improved the fuel cell performance, however the authors noted that this was still not RH. Adding the GO led to an even greater improvement in cell polarisation. Nafion/0.8Pt–TiO2/0.2GO sufficient at zero RH. Adding the GO led to an even greater improvement in cell polarisation. generatedacurrentdensityof0.54Acm−2at0.6Vat0%RH,whichcomparedtoNafion/Pt–TiO that −2 2 Nafion/0.8Pt–TiO2/0.2GO generated a current density of 0.54 A cm at 0.6 V at 0% RH, which produced a current density of 0.01 A cm−2 at the same RH. Furthermore, the introduction of GO not compared to Nafion/Pt–TiO2 that produced a current density of 0.01 A cm−2 at the same RH. only improved the current density generation, but also helped alleviate significant OCV loss when the Furthermore, the introduction of GO not only improved the current density generation, but also humidity was lowered. helped alleviate significant OCV loss when the humidity was lowered. Kim et al. [184] fabricated a GO/Nafion composite where the GO is modified with phosphotungstic Kim et al. [184] fabricated a GO/Nafion composite where the GO is modified with acid (H3[PW12O40]·29H2O) to aid water uptake and proton conduction at low relative humidity phosphotungstic acid (H3[PW12O40]·29H2O) to aid water uptake and proton conduction at low PEMFC operation. Fuel cell testing at 80 ◦C and 20% RH showed that the composite membrane with relative humidity PEMFC operation. Fuel cell testing at 80 °C and 20% RH showed that the modified GO produced a maximum power density of 841 mW cm−2, which is a great improvement composite membrane with modified GO produced a maximum power density of 841 mW cm−2, in comparison to non-acid doped Nafion/GO which generated 488 mW cm−2, and 208 mW cm−2 for which is a great improvement in comparison to non-acid doped Nafion/GO which generated 488 recast Nafion. Polarization curves are shown in Figure 7. mW cm−2, and 208 mW cm−2 for recast Nafion. Polarization curves are shown in Figure 7. Figure 7.. Polariizattiion and power density plots of Nafifion-212, recast Nafifion, Nafifion/mGO and ◦◦ Nafifion/PW--mGO operatiing ((a)) under 100% RH att 80 °C and ((b) under 20% RH at 80 °C. One weight percenttfiflillelerrcocnotnetnetnwtawsausseudseindcionmcpoomsipteosmitemmbreamnbesr,aanneds,cantadlycsattlaolaydsitnlgoiandtihnegainodtheeanadnocdaethoandde −2 −2 wcatshokdepetw0.a5smkegpctm0.5 m; rgepcrmodu; rcepdrowdituhcepderwmiitshsipoenrmfroismsio[1n8f4r]o.m [184]. Maiti et al. [185] synthesised a composite Nafion membrane comprising of graphene oxide and an Maiti et al. [185] synthesised a composite Nafion membrane comprising of graphene oxide and ionic liquid (dihydrogen phosphate functionalised imidazolium) for high temperature PEMFCs. TGA an ionic liquid (dihydrogen phosphate functionalised imidazolium) for high temperature PEMFCs. shows that the ionic liquid is stable up to 230 ◦C, which is more than enough for high temperature TGA shows that the ionic liquid is stable up to 230 °C, which is more than enough for high operation. The composite membranes displayed greater proton conductivity compared to Nafion 117 temperature operation. The composite membranes displayed greater proton conductivity compared throughout the entire temperature range tested (70–110 ◦C). This improved performance was carried to Nafion 117 throughout the entire temperature range tested (70-110 °C). This improved through to the single cell test where the composite membrane generated higher current densities in comparison to the Nafion 117 MEA (at 110 ◦C and dry conditions). Branco et al. [186] investigated the performance of multilayer membranes for IT-PEFC applications. Multilayer membranes with two external Nafion outer layers and an inner layer of graphene oxide and another with sulphonated polyindene were fabricated with solution casting and hot-pressing methods. The solution casting protocol involves heating the first Nafion layer at 100 ◦C for two hours to remove the solvents in the Nafion dispersion, followed by the addition of the graphene oxide solution/sulphonated polyindene (in deionized water) and another two hours at the same temperature. Lastly, the final Nafion layer was added and the multilayer membrane was heat treated for one hour at 120 ◦C. The increased temperature is to anneal the polymer. Multilayer membranes that were casted displayed better performance and proton conductivity than the hot-pressed multilayer membranes. This was explained by the casted membranes having better interface interaction compared to the hot-pressed membranes, which suffered delamination. Multilayer membranes with sulphonated polyindene showed higher performance than Nafion at 120 ◦C.PDF Image | Composite Polymers for Electrolyte Membrane Technologies

PDF Search Title:

Composite Polymers for Electrolyte Membrane TechnologiesOriginal File Name Searched:

molecules-25-01712.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |