PDF Publication Title:

Text from PDF Page: 027

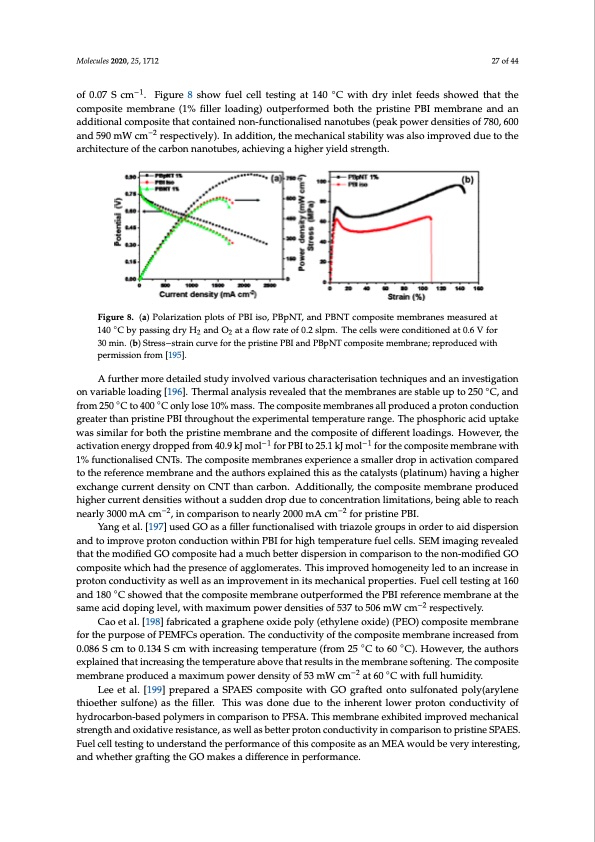

extent of acid leaching and to increase long term stability as increasing acid content can mechanically compromise the polymer. The addition of 1.5% phosphonated graphene oxide significantly increased the proton conductivity from 19.6 × 10−3 S cm-1 for pyridine PBI to 76.4 x 10−3 S cm−1 at 140 °C. Kannan et al. [195] presented a composite PBI membrane consisting of phosphonic acid Molecules 2020, 25, 1712 27 of 44 functionalised multi-walled carbon nanotubes as the filler material. Proton conductivity tests revealed that the composite membrane achieved 0.11 S cm−1, whereas the pristine PBI produced a −1 ◦ −1 ofc0o.n0d7uSctcivmityo.fF0.i0g7urSecm8sh.oFwigufruee8lschelolwtefsutienlgcealltt1e4st0ingCatw1i4th0°dCrywinthledtrfyeeindlsetsfheoewdsedshtohwaetdththeat cotmhepocosimtepmoseitmebmraenmeb(r1a%nefi(1ll%erfillolaerdilnogad) ionugt)poeurftopremrfoedrmbeodthboththetphreisptrinisetinPeBIPBmIemebmrabnreanaenadndanan adadidtiiotnioanl aclocmopmopsoitseitehtaht actocnotnaitnaeindendono-nfu-fnucnticotnioanliasleisdendanaontuotbuebse(sp(epaekapkopwoewredrednesnitsiietsieosfo7f8708, 06,06000 −2 anadn5d9509m0WmWcmcmrersepsepcetcivtievleyl)y.)I.nInadadidtiotino,nt,htehemmecehcahnainciaclasltsatbaiblitlyitywwasaaslasolsoimimprporvoevdedudeuteottohtehe −2 arcahrcitheictteucrtueroefothfethcearcbaorbnonanaontuobtuebs,eas,chaciehvieinvginaghaighhigehreyrieylidelsdtrsetnregnthg.th. Figure 8. (a) Polarization plots of PBI iso, PBpNT, and PBNT composite membranes measured at 140 Figure 8. (a) Polarization plots of PBI iso, PBpNT, and PBNT composite membranes measured at °C◦ by passing dry H2 and O2 at a flow rate of 0.2 slpm. The cells were conditioned at 0.6 V for 30 min. 140 C by passing dry H2 and O2 at a flow rate of 0.2 slpm. The cells were conditioned at 0.6 V for (b) Stress−strain curve for the pristine PBI and PBpNT composite membrane; reproduced with 30 min. (b) Stress−strain curve for the pristine PBI and PBpNT composite membrane; reproduced with permission from [195]. permission from [195]. A Afurtfhuerrthmeroremdoerteailedetsatuildedy insvtuodlvyedinvvaroilovuesdchvaararicoteursisacthioanratcetcehrnisiaqtuioens antedcahniqnuvestigaantdionan ◦ oninvvaerisatibglaetlioandoingv[a1r9ia6b].leThloeardminalga[n1a9l6y]s.iTshrevrmeaalledantahlaytstihseremvemalebdratnheastathresmtaebmleburapnteos2a5r0e sCta,balnedup ◦◦ frotom2250°C, taon4d00froCmo2n5ly0 l°oCseto104%00m°aCsso.nTlyhelocsoem1p0o%sitme amsse.mTbhreanceosmapllopsriotedmucemd barparnoetsonalclopnrdoudcutcioend a grpeartoetrotnhacnonpdruisctitnioenPgBrIetahtreorutghhaonutptrhisetienxepePrBimI tehnrtoaul tgehmopuetrtahtuerexrpaenrgime.eTnhtealptheomspheroartiucraecirdanugpeta.kTehe wapshsoismpihlaorifcoarcbidotuhptthaekeprwisatisnseimielamrbforarnbeoathndthteheprciosmtinpeomsitemobfrdainffeeraenndt tlhoaedcionmgsp.oHsitoewoefvdeirf,ftehrent −1 −1 −1 −1 acltoivaadtinongse.nHerogwyedvreorp,pthede afrcotmiva4t0io.9nkeJnmeorgly dfororpPpBeIdtof2ro5.m1k4J0m.9oklJ mforlthfeorcoPmBpIotosi2te5.m1ekmJ mbroanlefwoirththe 1%cofumnpcotisointealmisemd bCrNanTse.wTihthe c1o%mfpuonscitieomnaelmisebdraCneNsTesx.pTehrieecnocme aposmsitaellmeredmrobpraineascetixvpaetrioienncoemapsmaraedller todthroepreifnereanctcievamtieomnbcroanmepanrdedthteoatuhtehorresferxepnlcaeinmedetmhbisransethaencdatathlyestasu(tphlaotrisnuemxp)lahianveidngthaihsigahsetrhe excahtanlygsetscu(prlraetnintudmen)shitayvoingCaNhTigthearnecxacrhbaonng.eAcudrdrietniotndaelnlys,ityheocnoCmNpTostihteanmceamrborann.eApdrdoidtiuonceadlly, higtherccoumrrpeonstidteenmsietimesbwraintheouptroadsucdedenhdigrhoeprdcuuertroenctondcenstirtaiteisonwlimthiotautioanss,ubdeidnegnabdlreotpo rdeuaechto −2 −2 −2 necaornlyce3n0t0r0atmioAnclmimit,aitniocnosm,bpeairnisgoanbtloentoearelyac2h00n0eamrAlyc3m000fmorApcrmistin,einPBcoI.mparisontonearly2000 −2 mAYacnmgetfoarl.p[1ri9s7t]inuesePdBIG.Oasafillerfunctionalisedwithtriazolegroupsinordertoaiddispersion andtoYimanpgroveetparl.ot[o1n97c]onudsuedctiGonOwaitshianfPilBleIrfofruhnicgthiotneamlipsedratwuriethfuterliaczeollse.SgEroMupimsaigninogrdrevretaoledaid thdatistphermsiondifiaend GtoO icmomprpoovseitephroatdona mcouncdhubcettitoenr dwisiptheirnsioPnBIinfcoormhpigahristoenmtpoetrhaetunroen-fmueoldcifielelds. GSOEM coimpaogsiintge wrehviecahlehdadthtahtetphresmenocdeifoiefdagGgOlomcoemrapteoss.itTehhisaidmaprmovuecdh hboemtteorgdenisepiteyrslieodntoinacnoimncpraeraiseoninto proton conductivity as well as an improvement in its mechanical properties. Fuel cell testing at 160 and 180 ◦C showed that the composite membrane outperformed the PBI reference membrane at the same acid doping level, with maximum power densities of 537 to 506 mW cm−2 respectively. Cao et al. [198] fabricated a graphene oxide poly (ethylene oxide) (PEO) composite membrane for the purpose of PEMFCs operation. The conductivity of the composite membrane increased from 0.086 S cm to 0.134 S cm with increasing temperature (from 25 ◦C to 60 ◦C). However, the authors explained that increasing the temperature above that results in the membrane softening. The composite membrane produced a maximum power density of 53 mW cm−2 at 60 ◦C with full humidity. Lee et al. [199] prepared a SPAES composite with GO grafted onto sulfonated poly(arylene thioether sulfone) as the filler. This was done due to the inherent lower proton conductivity of hydrocarbon-based polymers in comparison to PFSA. This membrane exhibited improved mechanical strength and oxidative resistance, as well as better proton conductivity in comparison to pristine SPAES. Fuel cell testing to understand the performance of this composite as an MEA would be very interesting, and whether grafting the GO makes a difference in performance.PDF Image | Composite Polymers for Electrolyte Membrane Technologies

PDF Search Title:

Composite Polymers for Electrolyte Membrane TechnologiesOriginal File Name Searched:

molecules-25-01712.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |