PDF Publication Title:

Text from PDF Page: 029

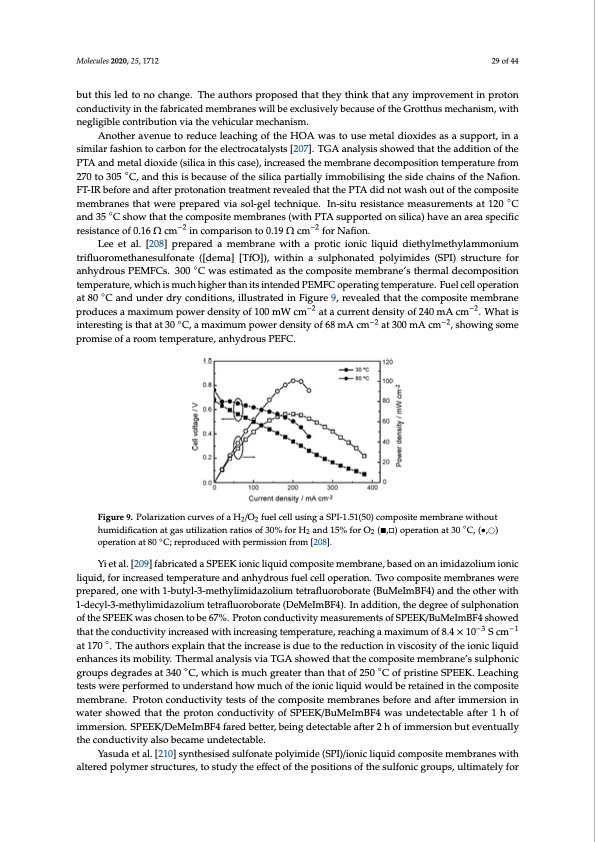

looking into the effect of extent of ion exchange. Composite membranes with 2, 1, and 0 protons left after substitution were prepared [206]. Weight loss measurements to assess the stability of PTA in Nafion were performed, with increasing proton substitution leading to less weight loss after protonation. Pristine PTA had a weight loss of around 27%, which decreased to less than 5% for the PTA modified to have its protons removed. Water uptake experiments interestingly showed that Molecules 2020, 25, 1712 29 of 44 there is no difference between pristine PTA composite and the substituted protons. In addition, membranes were also ion exchanged using different cations, but this led to no change. The authors but this led to no change. The authors proposed that they think that any improvement in proton proposed that they think that any improvement in proton conductivity in the fabricated membranes conductivity in the fabricated membranes will be exclusively because of the Grotthus mechanism, with will be exclusively because of the Grotthus mechanism, with negligible contribution via the negligible contribution via the vehicular mechanism. vehicular mechanism. Another avenue to reduce leaching of the HOA was to use metal dioxides as a support, in a Another avenue to reduce leaching of the HOA was to use metal dioxides as a support, in a similar fashion to carbon for the electrocatalysts [207]. TGA analysis showed that the addition of the similar fashion to carbon for the electrocatalysts [207]. TGA analysis showed that the addition of the PTA and metal dioxide (silica in this case), increased the membrane decomposition temperature from PTA and metal dioxide (silica in this case), increased the membrane decomposition temperature 270 to 305 ◦C, and this is because of the silica partially immobilising the side chains of the Nafion. from 270 to 305 °C, and this is because of the silica partially immobilising the side chains of the FT-IR before and after protonation treatment revealed that the PTA did not wash out of the composite Nafion. FT-IR before and after protonation treatment revealed that the PTA did not wash out of the membranes that were prepared via sol-gel technique. In-situ resistance measurements at 120 ◦C composite membranes that were prepared via sol-gel technique. In-situ resistance measurements at and 35 ◦C show that the composite membranes (with PTA supported on silica) have an area specific 120 °C and 35 °C show that the composite membranes (with PTA supported on silica) have an area resistanceof0.16Ωcm−2 incom−2parisonto0.19Ωcm−2 forN−a2fion. specific resistance of 0.16 Ω cm in comparison to 0.19 Ω cm for Nafion. Lee et al. [208] prepared a membrane with a protic ionic liquid diethylmethylammonium Lee et al. [208] prepared a membrane with a protic ionic liquid diethylmethylammonium trifluoromethanesulfonate ([dema] [TfO]), within a sulphonated polyimides (SPI) structure for trifluoromethanesulfonate ([dema] [TfO]), within a sulphonated polyimides (SPI) structure for anhydrous PEMFCs. 300 ◦C was estimated as the composite membrane’s thermal decomposition anhydrous PEMFCs. 300 °C was estimated as the composite membrane’s thermal decomposition temperature, which is much higher than its intended PEMFC operating temperature. Fuel cell operation temperature, which is much higher than its intended PEMFC operating temperature. Fuel cell at 80 ◦C and under dry conditions, illustrated in Figure 9, revealed that the composite membrane operation at 80 °C and under dry conditions, illustrated in Figure 9, revealed that the composite produces a maximum power density of 100 mW cm−2 at a curr−e2nt density of 240 mA cm−2. What −i2s membrane produces a maximum power density of 100 mW cm at a current density of 240 mA cm . interesting is that at 30 ◦C, a maximum power density of 68 mA cm−2 at 300 mA cm−2−2, showing som−2e What is interesting is that at 30 °C, a maximum power density of 68 mA cm at 300 mA cm , promise of a room temperature, anhydrous PEFC. showing some promise of a room temperature, anhydrous PEFC. Figure9.PolarizationcurvesofaH2/O2 fuelcellusingaSPI-1.51(50)compositemembranewithout 22 ◦ ◦ humidiffiication at gas utilization ratios of 30% for H2 and 15% for O2 (■,□) operation at 30 °C, (•●,,○) 22 operation at 80°C;;rreprroduced wiitth permiissiion from [208]. Yi et al. [209] fabricated a SPEEK ionic liquid composite membrane, based on an imidazolium ionic liquid, for increased temperature and anhydrous fuel cell operation. Two composite membranes were prepared, one with 1-butyl-3-methylimidazolium tetrafluoroborate (BuMeImBF4) and the other with 1-decyl-3-methylimidazolium tetrafluoroborate (DeMeImBF4). In addition, the degree of sulphonation of the SPEEK was chosen to be 67%. Proton conductivity measurements of SPEEK/BuMeImBF4 showed that the conductivity increased with increasing temperature, reaching a maximum of 8.4 × 10−3 S cm−1 at 170 ◦. The authors explain that the increase is due to the reduction in viscosity of the ionic liquid enhances its mobility. Thermal analysis via TGA showed that the composite membrane’s sulphonic groups degrades at 340 ◦C, which is much greater than that of 250 ◦C of pristine SPEEK. Leaching tests were performed to understand how much of the ionic liquid would be retained in the composite membrane. Proton conductivity tests of the composite membranes before and after immersion in water showed that the proton conductivity of SPEEK/BuMeImBF4 was undetectable after 1 h of immersion. SPEEK/DeMeImBF4 fared better, being detectable after 2 h of immersion but eventually the conductivity also became undetectable. Yasuda et al. [210] synthesised sulfonate polyimide (SPI)/ionic liquid composite membranes with altered polymer structures, to study the effect of the positions of the sulfonic groups, ultimately forPDF Image | Composite Polymers for Electrolyte Membrane Technologies

PDF Search Title:

Composite Polymers for Electrolyte Membrane TechnologiesOriginal File Name Searched:

molecules-25-01712.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |