PDF Publication Title:

Text from PDF Page: 066

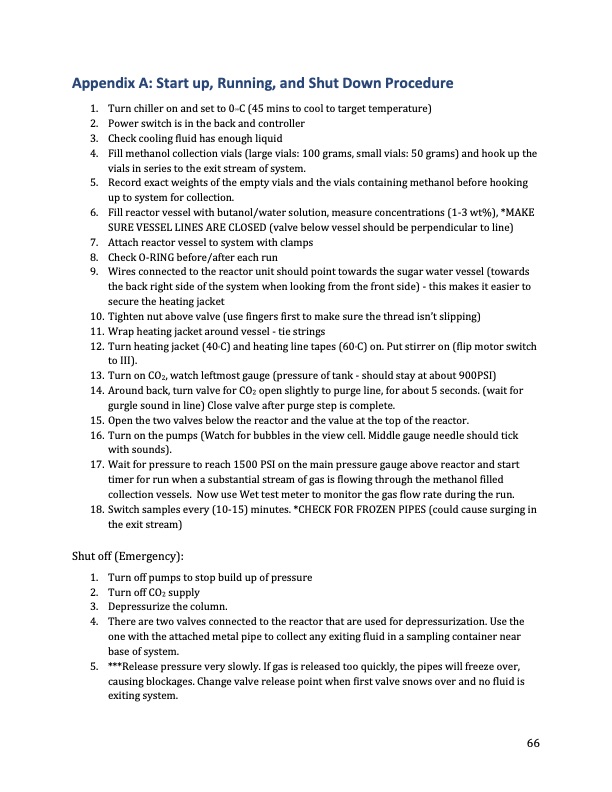

Appendix A: Start up, Running, and Shut Down Procedure 1. Turn chiller on and set to 0ooC (45 mins to cool to target temperature) 2. Power switch is in the back and controller 3. Check cooling fluid has enough liquid 4. Fill methanol collection vials (large vials: 100 grams, small vials: 50 grams) and hook up the vials in series to the exit stream of system. 5. Record exact weights of the empty vials and the vials containing methanol before hooking up to system for collection. 6. Fill reactor vessel with butanol/water solution, measure concentrations (1-3 wt%), *MAKE SURE VESSEL LINES ARE CLOSED (valve below vessel should be perpendicular to line) 7. Attach reactor vessel to system with clamps 8. Check O-RING before/after each run 9. Wires connected to the reactor unit should point towards the sugar water vessel (towards the back right side of the system when looking from the front side) - this makes it easier to secure the heating jacket 10. Tighten nut above valve (use fingers first to make sure the thread isn’t slipping) 11. Wrap heating jacket around vessel - tie strings 12. Turn heating jacket (40oC) and heating line tapes (60oC) on. Put stirrer on (flip motor switch to III). 13. Turn on CO2, watch leftmost gauge (pressure of tank - should stay at about 900PSI) 14. Around back, turn valve for CO2 open slightly to purge line, for about 5 seconds. (wait for gurgle sound in line) Close valve after purge step is complete. 15. Open the two valves below the reactor and the value at the top of the reactor. 16. Turn on the pumps (Watch for bubbles in the view cell. Middle gauge needle should tick with sounds). 17. Wait for pressure to reach 1500 PSI on the main pressure gauge above reactor and start timer for run when a substantial stream of gas is flowing through the methanol filled collection vessels. Now use Wet test meter to monitor the gas flow rate during the run. 18. Switch samples every (10-15) minutes. *CHECK FOR FROZEN PIPES (could cause surging in the exit stream) Shut off (Emergency): 1. Turn off pumps to stop build up of pressure 2. Turn off CO2 supply 3. Depressurize the column. 4. There are two valves connected to the reactor that are used for depressurization. Use the one with the attached metal pipe to collect any exiting fluid in a sampling container near base of system. 5. ***Release pressure very slowly. If gas is released too quickly, the pipes will freeze over, causing blockages. Change valve release point when first valve snows over and no fluid is exiting system. 66PDF Image | Extraction of Bio-Butanol using Supercritical Carbon Dioxide

PDF Search Title:

Extraction of Bio-Butanol using Supercritical Carbon DioxideOriginal File Name Searched:

MQP_FINAL_REPORT.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |