PDF Publication Title:

Text from PDF Page: 119

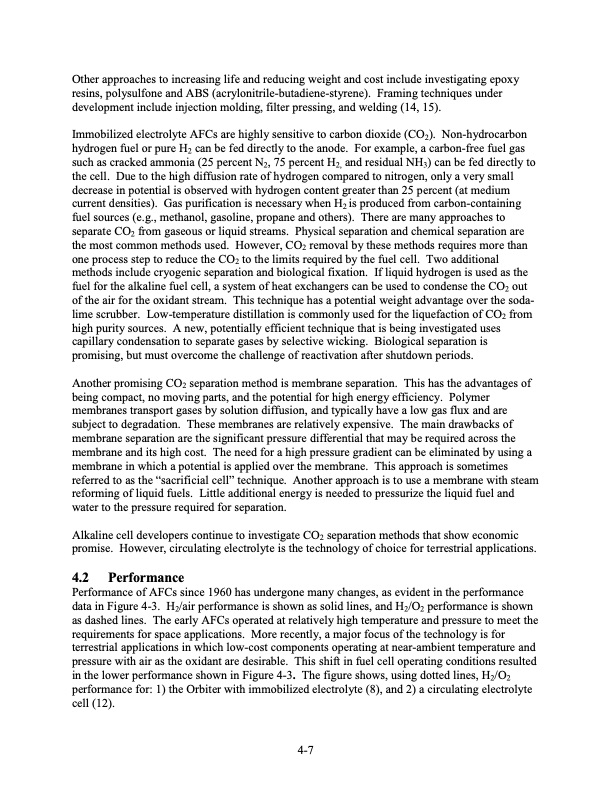

Other approaches to increasing life and reducing weight and cost include investigating epoxy resins, polysulfone and ABS (acrylonitrile-butadiene-styrene). Framing techniques under development include injection molding, filter pressing, and welding (14, 15). Immobilized electrolyte AFCs are highly sensitive to carbon dioxide (CO2). Non-hydrocarbon hydrogen fuel or pure H2 can be fed directly to the anode. For example, a carbon-free fuel gas such as cracked ammonia (25 percent N2, 75 percent H2, and residual NH3) can be fed directly to the cell. Due to the high diffusion rate of hydrogen compared to nitrogen, only a very small decrease in potential is observed with hydrogen content greater than 25 percent (at medium current densities). Gas purification is necessary when H2 is produced from carbon-containing fuel sources (e.g., methanol, gasoline, propane and others). There are many approaches to separate CO2 from gaseous or liquid streams. Physical separation and chemical separation are the most common methods used. However, CO2 removal by these methods requires more than one process step to reduce the CO2 to the limits required by the fuel cell. Two additional methods include cryogenic separation and biological fixation. If liquid hydrogen is used as the fuel for the alkaline fuel cell, a system of heat exchangers can be used to condense the CO2 out of the air for the oxidant stream. This technique has a potential weight advantage over the soda- lime scrubber. Low-temperature distillation is commonly used for the liquefaction of CO2 from high purity sources. A new, potentially efficient technique that is being investigated uses capillary condensation to separate gases by selective wicking. Biological separation is promising, but must overcome the challenge of reactivation after shutdown periods. Another promising CO2 separation method is membrane separation. This has the advantages of being compact, no moving parts, and the potential for high energy efficiency. Polymer membranes transport gases by solution diffusion, and typically have a low gas flux and are subject to degradation. These membranes are relatively expensive. The main drawbacks of membrane separation are the significant pressure differential that may be required across the membrane and its high cost. The need for a high pressure gradient can be eliminated by using a membrane in which a potential is applied over the membrane. This approach is sometimes referred to as the “sacrificial cell” technique. Another approach is to use a membrane with steam reforming of liquid fuels. Little additional energy is needed to pressurize the liquid fuel and water to the pressure required for separation. Alkaline cell developers continue to investigate CO2 separation methods that show economic promise. However, circulating electrolyte is the technology of choice for terrestrial applications. 4.2 Performance Performance of AFCs since 1960 has undergone many changes, as evident in the performance data in Figure 4-3. H2/air performance is shown as solid lines, and H2/O2 performance is shown as dashed lines. The early AFCs operated at relatively high temperature and pressure to meet the requirements for space applications. More recently, a major focus of the technology is for terrestrial applications in which low-cost components operating at near-ambient temperature and pressure with air as the oxidant are desirable. This shift in fuel cell operating conditions resulted in the lower performance shown in Figure 4-3. The figure shows, using dotted lines, H2/O2 performance for: 1) the Orbiter with immobilized electrolyte (8), and 2) a circulating electrolyte cell (12). 4-7PDF Image | Fuel Cell Handbook (Seventh Edition)

PDF Search Title:

Fuel Cell Handbook (Seventh Edition)Original File Name Searched:

fuel-cell-handbook.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |