PDF Publication Title:

Text from PDF Page: 248

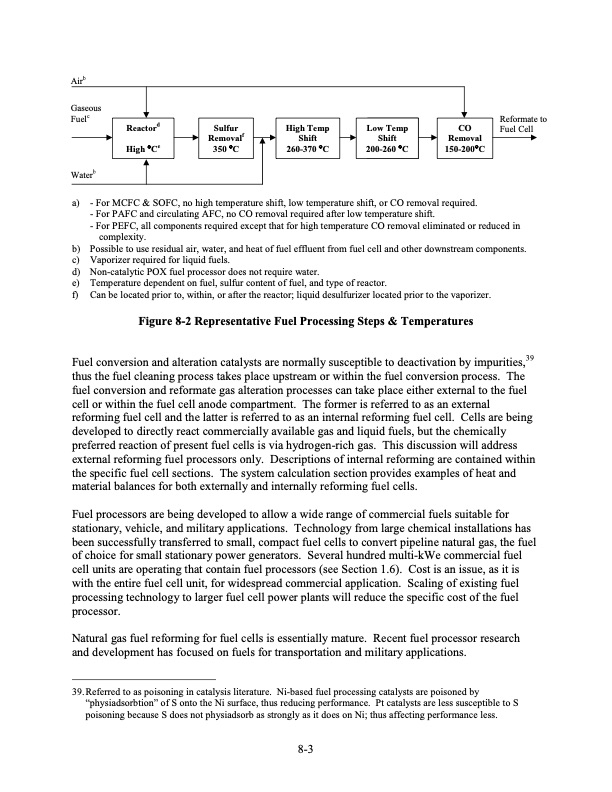

Airb Waterb a) - For MCFC & SOFC, no high temperature shift, low temperature shift, or CO removal required. - For PAFC and circulating AFC, no CO removal required after low temperature shift. - For PEFC, all components required except that for high temperature CO removal eliminated or reduced in complexity. b) Possible to use residual air, water, and heat of fuel effluent from fuel cell and other downstream components. c) V aporizer required for liquid fuels. d) Non-catalytic POX fuel processor does not require water. e) Temperature dependent on fuel, sulfur content of fuel, and type of reactor. f) Can be located prior to, within, or after the reactor; liquid desulfurizer located prior to the vaporizer. Figure 8-2 Representative Fuel Processing Steps & Temperatures Fuel conversion and alteration catalysts are normally susceptible to deactivation by impurities,39 thus the fuel cleaning process takes place upstream or within the fuel conversion process. The fuel conversion and reformate gas alteration processes can take place either external to the fuel cell or within the fuel cell anode compartment. The former is referred to as an external reforming fuel cell and the latter is referred to as an internal reforming fuel cell. Cells are being developed to directly react commercially available gas and liquid fuels, but the chemically preferred reaction of present fuel cells is via hydrogen-rich gas. This discussion will address external reforming fuel processors only. Descriptions of internal reforming are contained within the specific fuel cell sections. The system calculation section provides examples of heat and material balances for both externally and internally reforming fuel cells. Fuel processors are being developed to allow a wide range of commercial fuels suitable for stationary, vehicle, and military applications. Technology from large chemical installations has been successfully transferred to small, compact fuel cells to convert pipeline natural gas, the fuel of choice for small stationary power generators. Several hundred multi-kWe commercial fuel cell units are operating that contain fuel processors (see Section 1.6). Cost is an issue, as it is with the entire fuel cell unit, for widespread commercial application. Scaling of existing fuel processing technology to larger fuel cell power plants will reduce the specific cost of the fuel processor. Natural gas fuel reforming for fuel cells is essentially mature. Recent fuel processor research and development has focused on fuels for transportation and military applications. 39.Referred to as poisoning in catalysis literature. Ni-based fuel processing catalysts are poisoned by “physiadsorbtion” of S onto the Ni surface, thus reducing performance. Pt catalysts are less susceptible to S poisoning because S does not physiadsorb as strongly as it does on Ni; thus affecting performance less. Gaseous Fuelc Reformate to Fuel Cell Reactord High °Ce Sulfur Removalf 350 °C High Temp Shift 260-370 °C Low Temp Shift 200-260 °C CO Removal 150-200°C 8-3PDF Image | Fuel Cell Handbook (Seventh Edition)

PDF Search Title:

Fuel Cell Handbook (Seventh Edition)Original File Name Searched:

fuel-cell-handbook.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |