PDF Publication Title:

Text from PDF Page: 003

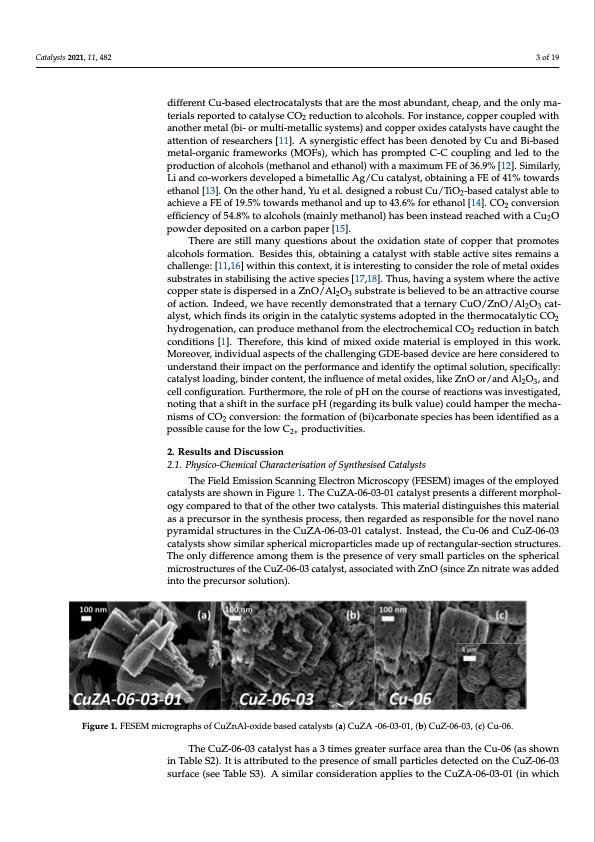

Catalysts 2021, 11, x FOR PEER REVIEW 3 of 19 Catalysts 2021, 11, 482 overcome the limitations of operation with dissolved CO2 and pursue commercially-3roefle19- vant current densities. The electrochemical CO2 conversion was here performed on differ- ent Cu-based electrocatalysts that are the most abundant, cheap, and the only materials reported to catalyse CO2 reduction to alcohols. For instance, copper coupled with another different Cu-based electrocatalysts that are the most abundant, cheap, and the only ma- metal (bi- or multi-metallic systems) and copper oxides catalysts have caught the attention terials reported to catalyse CO2 reduction to alcohols. For instance, copper coupled with of researchers [11]. A synergistic effect has been denoted by Cu and Bi-based metal-or- another metal (bi- or multi-metallic systems) and copper oxides catalysts have caught the ganic frameworks (MOFs), which has prompted C-C coupling and led to the production attention of researchers [11]. A synergistic effect has been denoted by Cu and Bi-based of alcohols (methanol and ethanol) with a maximum FE of 36.9% [12]. Similarly, Li and metal-organic frameworks (MOFs), which has prompted C-C coupling and led to the co-workers developed a bimetallic Ag/Cu catalyst, obtaining a FE of 41% towards ethanol production of alcohols (methanol and ethanol) with a maximum FE of 36.9% [12]. Similarly, [13]. On the other hand, Yu et al. designed a robust Cu/TiO2-based catalyst able to achieve Li and co-workers developed a bimetallic Ag/Cu catalyst, obtaining a FE of 41% towards a FE of 19.5% towards methanol and up to 43.6% for ethanol [14]. CO2 conversion effi- ethanol [13]. On the other hand, Yu et al. designed a robust Cu/TiO2-based catalyst able to ciency of 54.8% to alcohols (mainly methanol) has been instead reached with a Cu2O pow- achieve a FE of 19.5% towards methanol and up to 43.6% for ethanol [14]. CO2 conversion der deposited on a carbon paper [15]. efficiency of 54.8% to alcohols (mainly methanol) has been instead reached with a Cu2O There are still many questions about the oxidation state of copper that promotes al- powder deposited on a carbon paper [15]. cohols formation. Besides this, obtaining a catalyst with stable active sites remains a chal- There are still many questions about the oxidation state of copper that promotes lenge: [11,16]within this context, it is interesting to consider the role of metal oxides sub- alcohols formation. Besides this, obtaining a catalyst with stable active sites remains a strates in stabilising the active species [17,18]. Thus, having a system where the active challenge: [11,16] within this context, it is interesting to consider the role of metal oxides copper state is dispersed in a ZnO/Al2O3 substrate is believed to be an attractive course of substrates in stabilising the active species [17,18]. Thus, having a system where the active action. Indeed, we have recently demonstrated that a ternary CuO/ZnO/Al2O3 catalyst, copper state is dispersed in a ZnO/Al2O3 substrate is believed to be an attractive course which finds its origin in the catalytic systems adopted in the thermocatalytic CO2 hydro- of action. Indeed, we have recently demonstrated that a ternary CuO/ZnO/Al2O3 cat- genation, can produce methanol from the electrochemical CO2 reduction in batch condi- alyst, which finds its origin in the catalytic systems adopted in the thermocatalytic CO2 tions [1]. Therefore, this kind of mixed oxide material is employed in this work. Moreover, hydrogenation, can produce methanol from the electrochemical CO2 reduction in batch individual aspects of the challenging GDE-based device are here considered to under- conditions [1]. Therefore, this kind of mixed oxide material is employed in this work. stand their impact on the performance and identify the optimal solution, specifically: cat- Moreover, individual aspects of the challenging GDE-based device are here considered to alyst loading, binder content, the influence of metal oxides, like ZnO or/and Al2O3, and understand their impact on the performance and identify the optimal solution, specifically: cell configuration. Furthermore, the role of pH on the course of reactions was investigated, catalyst loading, binder content, the influence of metal oxides, like ZnO or/and Al2O3, and noting that a shift in the surface pH (regarding its bulk value) could hamper the mecha- cell configuration. Furthermore, the role of pH on the course of reactions was investigated, nisms of CO2 conversion: the formation of (bi)carbonate species has been identified as a noting that a shift in the surface pH (regarding its bulk value) could hamper the mecha- possible cause for the low C2+ productivities. nisms of CO2 conversion: the formation of (bi)carbonate species has been identified as a possible cause for the low C2+ productivities. 2. Results and Discussions 2. Results and Discussion 2.1. Physico-Chemical Characterisation of Synthesised Catalysts 2.1. Physico-Chemical Characterisation of Synthesised Catalysts The Field Emission Scanning Electron Microscopy (FESEM) images of the employed The Field Emission Scanning Electron Microscopy (FESEM) images of the employed catalysts are shown in Figure 1. The CuZA-06-03-01 catalyst presents a different morphol- catalysts are shown in Figure 1. The CuZA-06-03-01 catalyst presents a different morphol- ogy compared to that of the other two catalysts. This material distinguishes this material ogy compared to that of the other two catalysts. This material distinguishes this material as a precursor in the synthesis process, then regarded as responsible for the novel nano as a precursor in the synthesis process, then regarded as responsible for the novel nano pyramidal structures in the CuZA-06-03-01 catalyst. Instead, the Cu-06 and CuZ-06-03 pyramidal structures in the CuZA-06-03-01 catalyst. Instead, the Cu-06 and CuZ-06-03 catalysts show similar spherical microparticles made up of rectangular-section structures. catalysts show similar spherical microparticles made up of rectangular-section structures. The only difference among them is the presence of very small particles on the spherical The only difference among them is the presence of very small particles on the spherical microstructures of the CuZ-06-03 catalyst, associated with ZnO (since Zn nitrate was microstructures of the CuZ-06-03 catalyst, associated with ZnO (since Zn nitrate was added added into the precursor solution). into the precursor solution). Figure 1. FESEM micrographs of CuZnAl-oxide based catalysts (a) CuZA -06-03-01, (b) CuZ-06-03, (c) Cu-06. Figure 1. FESEM micrographs of CuZnAl-oxide based catalysts (a) CuZA -06-03-01, (b) CuZ-06-03, (c) Cu-06. The CuZ-06-03 catalyst has a 3 times greater surface area than the Cu-06 (as shown in Table S2). It is attributed to the presence of small particles detected on the CuZ-06-03 surface (see Table S3). A similar consideration applies to the CuZA-06-03-01 (in whichPDF Image | Gas Diffusion Electrode Systems for the Electro CO2 Conversion

PDF Search Title:

Gas Diffusion Electrode Systems for the Electro CO2 ConversionOriginal File Name Searched:

catalysts-11-00482.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |