PDF Publication Title:

Text from PDF Page: 006

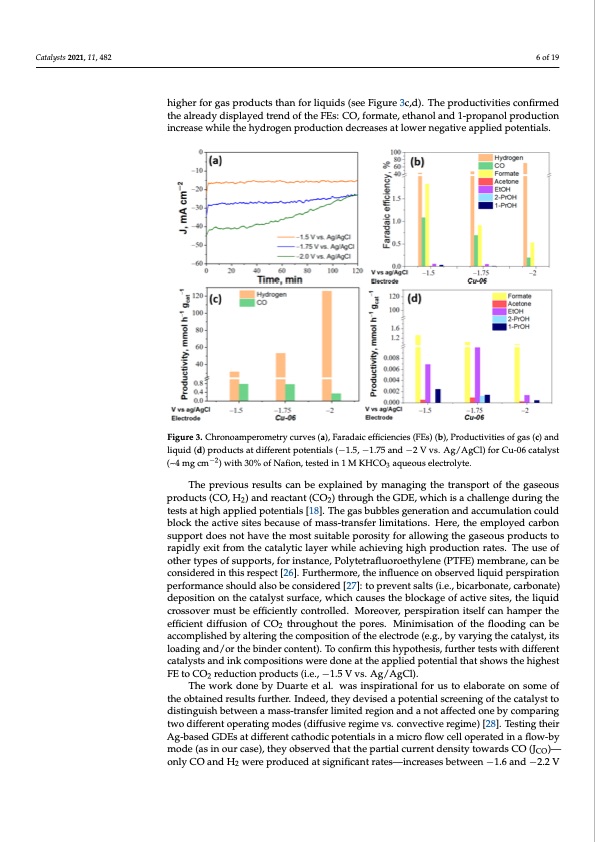

Catalysts 2021, 11, x FOR PEER REVIEW 6 of Catalysts 2021, 11, 482 6 of 19 at −2 V vs. Ag/AgCl, the current density decreased by about 12% and reached the sa higher for gas products than for liquids (see Figure 3c,d). The productivities confirmed −2 vathlueealorfeatdhyedteisptlcaoynedturcenteddoafth−e1F.7E5s:VC(Oi.,ef.o,r−m2a9tem, eAthcamnol)a.nd 1-propanol production increase while the hydrogen production decreases at lower negative applied potentials. Figure 3. Chronoamperometry curves (a), Faradaic efficiencies (FEs) (b), Productivities of gas (c) and Figure 3. Chronoamperometry curves (a), Faradaic efficiencies (FEs) (b), Productivities of gas (c) liquid (d) products at different potentials (−1.5, −1.75 and −2 V vs. Ag/AgCl) for Cu-06 catalyst and liquid (−d2) products at different potentials (−1.5, −1.75 and −2 V vs. Ag/AgCl) for Cu-06 cataly (~4 mg cm ) with 30% of Nafion, tested in 1 M KHCO3 aqueous electrolyte. (~4 mg cm−2) with 30% of Nafion, tested in 1 M KHCO3 aqueous electrolyte. The previous results can be explained by managing the transport of the gaseous products (CO, H ) and reactant (CO ) through the GDE, which is a challenge during the In Figure 3b2 of the same figu2re, the FEs are reported. It can be observed that H2 a tests at high applied potentials [18]. The gas bubbles generation and accumulation could CO formation varies disproportionately with the applied potentials. Particularly, CO a block the active sites because of mass-transfer limitations. Here, the employed carbon formate formation decreases at the most negative potential (−2 V vs. Ag/AgCl) and t support does not have the most suitable porosity for allowing the gaseous products to production of alcohols, like ethanol and 1-propanol. Besides, the highest FE to H2 rapidly exit from the catalytic layer while achieving high production rates. The use of reached at −2V vs. Ag/AgCl. This behaviour indicates that the side reaction (HER) is other types of supports, for instance, Polytetrafluoroethylene (PTFE) membrane, can be vocuonrseideartedhignhthaisprpelsipeedctp[o26te].nFtuiarltsheirnmstoerae,dthoefiCnfl2+upernocedounctosb.sTehrviesdfilniqduiindgpiesrsnpoirtaitnioangreeme performance should also be considered [27]: to prevent salts (i.e., bicarbonate, carbonate) with what was claimed by Lv et al., namely that C-C coupling should be promoted at hi deposition on the catalyst surface, which causes the blockage of active sites, the liquid overpotentials through the further conversion of surface bond CO, while HER should crossover must be efficiently controlled. Moreover, perspiration itself can hamper the suppressed [25]. Indeed, at −2 V vs. Ag/AgCl, the productivity is two orders of magnitu efficient diffusion of CO2 throughout the pores. Minimisation of the flooding can be higher for gas products than for liquids (see Figure 3c,d). The productivities confirm accomplished by altering the composition of the electrode (e.g., by varying the catalyst, its the already displayed trend of the FEs: CO, formate, ethanol and 1-propanol producti loading and/or the binder content). To confirm this hypothesis, further tests with different incarteaalyssetswahndileintkhecohmypdorsoitgioenspwreordeudcotnieonatdtheecraepapsleiesdaptoltoewnteiarlntheagtasthivowesapthpelhieigdhpesottentials FEtoCO reductionproducts(i.e.,−1.5Vvs.Ag/AgCl). The p2 revious results can be explained by managing the transport of the gaseo The work done by Duarte et al. was inspirational for us to elaborate on some of products (CO, H2) and reactant (CO2) through the GDE, which is a challenge during t the obtained results further. Indeed, they devised a potential screening of the catalyst to tests at high applied potentials [18]. The gas bubbles generation and accumulation cou distinguish between a mass-transfer limited region and a not affected one by comparing block the active sites because of mass-transfer limitations. Here, the employed carbon su two different operating modes (diffusive regime vs. convective regime) [28]. Testing their port does not have the most suitable porosity for allowing the gaseous products to rapid Ag-based GDEs at different cathodic potentials in a micro flow cell operated in a flow-by exmitofdreom(astihneocuartacalyset)i,ctlhaeyeorbwsehrviledatchhaitetvhienpgarhtigalhcuprroedntudcetinosnityratotewsa.rTdhseCuOse(Jof)o—thertyp CO onlyCOandH wereproducedatsignificantrates—increasesbetween−1.6and−2.2V of supports, for2instance, Polytetrafluoroethylene (PTFE) membrane, can be considered this respect [26]. Furthermore, the influence on observed liquid perspiration performan should also be considered [27]: to prevent salts (i.e., bicarbonate, carbonate) deposition the catalyst surface, which causes the blockage of active sites, the liquid crossover m be efficiently controlled. Moreover, perspiration itself can hamper the efficient diffusi of CO2 throughout the pores. Minimisation of the flooding can be accomplished by alt m n n h f g b d e o u h o u o ePDF Image | Gas Diffusion Electrode Systems for the Electro CO2 Conversion

PDF Search Title:

Gas Diffusion Electrode Systems for the Electro CO2 ConversionOriginal File Name Searched:

catalysts-11-00482.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |