PDF Publication Title:

Text from PDF Page: 009

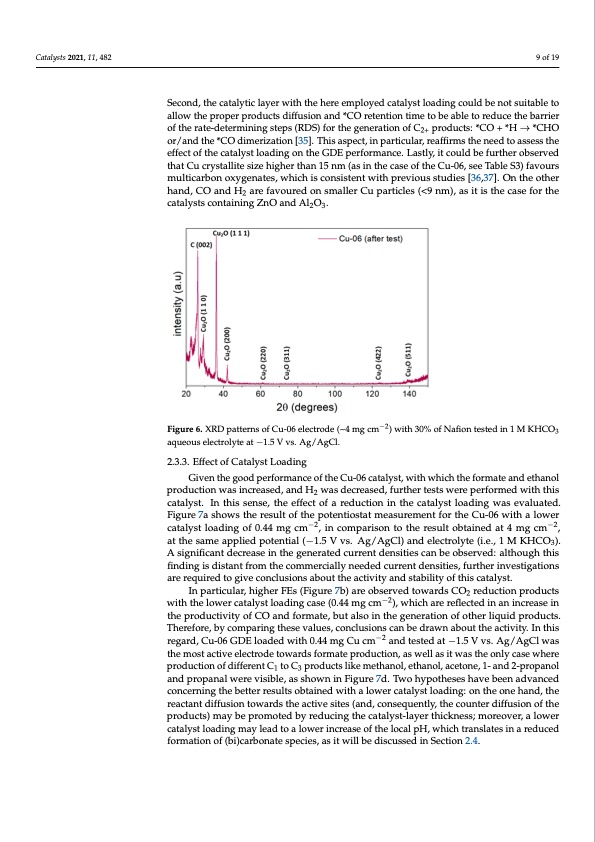

Catalysts 2021, 11, 482 9 of 19 Catalysts 2021, 11, x FOR PEER REVIEW 9 of 19 Second, the catalytic layer with the here employed catalyst loading could be not suitable to allow the proper products diffusion and *CO retention time to be able to reduce the barrier of the rate-determining steps (RDS) for the generation of C2+ products: *CO + *H → *CHO sented a greenish-white colour. It is plausible the CuO transformation to copper(II) hy- or/and the *CO dimerization [35]. This aspect, in particular, reaffirms the need to assess the droxy carbonates (malachite or azurite) during the electroreduction of CO2 in water, as effect of the catalyst loading on the GDE performance. Lastly, it could be further observed reported in the literature [31]. Thus, the results demonstrated that the formation and in that Cu crystallite size higher than 15 nm (as in the case of the Cu-06, see Table S3) favours situ stabilisation of Cu1+ contributes to improving the selectivity to more reduced CO2 re- multicarbon oxygenates, which is consistent with previous studies [36,37]. On the other duction products, like ethanol and 1-propanol, that were found with this oxide-derived hand, CO and H2 are favoured on smaller Cu particles (<9 nm), as it is the case for the copper [32]. catalysts containing ZnO and Al2O3. −2 FiFgiugruere6.6X. RXDRDpaptatettrenrsnosfoCf uC-u0-606elelcetcrotrdoed(e~(4~m4 mg cgmcm) w)itwhi3t0h%30o%f NofafNioanfiotenstedsteind1inM1KMHKCHOC3 O3 aqauqeuoeuosuselelcetcrtorloyltyeteata−t1−.51.V5 Vvsv. As.gA/Ag/gAClg.Cl. 2.3.3. Effect of Catalyst Loading By focusing on CuZA-06-03-01 and CuZ-06-03, a greater CO and formate production can be noted in the former case. Three possible reasons for this behaviour are here pro- productionwasincreased,andH wasdecreased,furthertestswereperformedwiththis posed. First, it might be associated2 with a significant role played by aluminium oxide in catalyst. In this sense, the effect of a reduction in the catalyst loading was evaluated. decreasing the binding energy for *CO. Thus the *CO could be easily desorbed as a CO Figure 7a shows the result of the potentiostat measurement for the Cu-06 with a lower molecule [33,34]. Second, the catalytic layer with the here employed catalyst loading could catalyst loading of 0.44 mg cm−2, in comparison to the result obtained at 4 mg cm−2, be not suitable to allow the proper products diffusion and *CO retention time to be able at the same applied potential (−1.5 V vs. Ag/AgCl) and electrolyte (i.e., 1 M KHCO ). to reduce the barrier of the rate-determining steps (RDS) for the generation of C2+ prod3- A significant decrease in the generated current densities can be observed: although this ucts: *CO + *H → *CHO or/and the *CO dimerization [35]. This aspect, in particular, reaf- finding is distant from the commercially needed current densities, further investigations −2 Given the good performance of the Cu-06 catalyst, with which the formate and ethanol firms the need to assess the effect of the catalyst loading on the GDE performance. Lastly, are required to give conclusions about the activity and stability of this catalyst. it could be further observed that Cu crystallite size higher than 15 nm (as in the case of the In particular, higher FEs (Figure 7b) are observed towards CO Cu-06, see Table S3) favours multicarbon oxygenates, which is consistent with previous reduction products with the lower catalyst loading case (0.44 mg cm−2), which are reflected in an increase in studies [36,37]]. On the other hand, CO and H2 are favoured on smaller Cu particles (<9 the productivity of CO and formate, but also in the generation of other liquid products. nm), as it is the case for the catalysts containing ZnO and Al2O3. Therefore, by comparing these values, conclusions can be drawn about the activity. In this regard, Cu-06 GDE loaded with 0.44 mg Cu cm−2 and tested at −1.5 V vs. Ag/AgCl was 2.3.3. Effect of Catalyst Loading the most active electrode towards formate production, as well as it was the only case where Given the good performance of the Cu-06 catalyst, with which the formate and etha- production of different C1 to C3 products like methanol, ethanol, acetone, 1- and 2-propanol nol production was increased, and H2 was decreased, further tests were performed with and propanal were visible, as shown in Figure 7d. Two hypotheses have been advanced this catalyst. In this sense, the effect of a reduction in the catalyst loading was evaluated. concerning the better results obtained with a lower catalyst loading: on the one hand, the Figure 7a shows the result of the potentiostat measurement for the Cu-06 with a lower reactant diffusion towards the active sites (and, consequently, the counter diffusion of the catalyst loading of 0.44 mg cm−2, in comparison to the result obtained at 4 mg cm−2, at the products) may be promoted by reducing the catalyst-layer thickness; moreover, a lower same applied potential (−1.5 V vs. Ag/AgCl) and electrolyte (i.e., 1 M KHCO3). A signifi- catalyst loading may lead to a lower increase of the local pH, which translates in a reduced cant decrease in the generated current densities can be observed: although this finding is formation of (bi)carbonate species, as it will be discussed in Section 2.4. distant from the commercially needed current densities, further investigations are re- quired to give conclusions about the activity and stability of this catalyst. 2PDF Image | Gas Diffusion Electrode Systems for the Electro CO2 Conversion

PDF Search Title:

Gas Diffusion Electrode Systems for the Electro CO2 ConversionOriginal File Name Searched:

catalysts-11-00482.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |