PDF Publication Title:

Text from PDF Page: 017

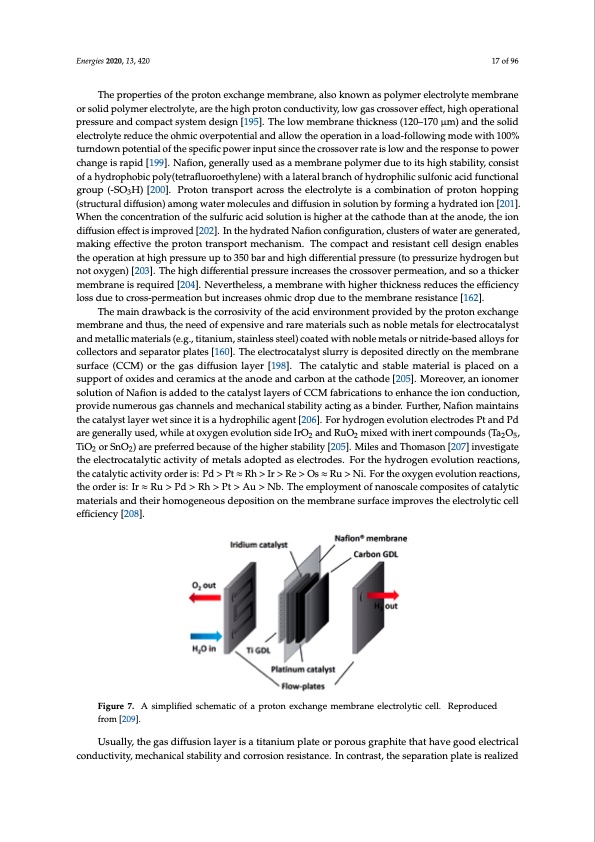

Energies 2020, 13, 420 17 of 96 The properties of the proton exchange membrane, also known as polymer electrolyte membrane or solid polymer electrolyte, are the high proton conductivity, low gas crossover effect, high operational pressure and compact system design [195]. The low membrane thickness (120–170 μm) and the solid electrolyte reduce the ohmic overpotential and allow the operation in a load-following mode with 100% turndown potential of the specific power input since the crossover rate is low and the response to power change is rapid [199]. Nafion, generally used as a membrane polymer due to its high stability, consist of a hydrophobic poly(tetrafluoroethylene) with a lateral branch of hydrophilic sulfonic acid functional group (-SO3H) [200]. Proton transport across the electrolyte is a combination of proton hopping (structural diffusion) among water molecules and diffusion in solution by forming a hydrated ion [201]. When the concentration of the sulfuric acid solution is higher at the cathode than at the anode, the ion diffusion effect is improved [202]. In the hydrated Nafion configuration, clusters of water are generated, making effective the proton transport mechanism. The compact and resistant cell design enables the operation at high pressure up to 350 bar and high differential pressure (to pressurize hydrogen but not oxygen) [203]. The high differential pressure increases the crossover permeation, and so a thicker membrane is required [204]. Nevertheless, a membrane with higher thickness reduces the efficiency loss due to cross-permeation but increases ohmic drop due to the membrane resistance [162]. The main drawback is the corrosivity of the acid environment provided by the proton exchange membrane and thus, the need of expensive and rare materials such as noble metals for electrocatalyst and metallic materials (e.g., titanium, stainless steel) coated with noble metals or nitride-based alloys for collectors and separator plates [160]. The electrocatalyst slurry is deposited directly on the membrane surface (CCM) or the gas diffusion layer [198]. The catalytic and stable material is placed on a support of oxides and ceramics at the anode and carbon at the cathode [205]. Moreover, an ionomer solution of Nafion is added to the catalyst layers of CCM fabrications to enhance the ion conduction, provide numerous gas channels and mechanical stability acting as a binder. Further, Nafion maintains Energies 2020, 13, x FOR PEER REVIEW 17 of 95 the catalyst layer wet since it is a hydrophilic agent [206]. For hydrogen evolution electrodes Pt and Pd aregenerallyused,whileatoxygenevolutionsideIrO andRuO mixedwithinertcompounds(TaO, the oxygen evolution reactions, the order is: Ir ≈ Ru2> Pd > Rh2> Pt > Au > Nb. The employmen2t o5f TiO orSnO)arepreferredbecauseofthehigherstability[205].MilesandThomason[207]investigate nan2oscale c2omposites of catalytic materials and their homogeneous deposition on the membrane the electrocatalytic activity of metals adopted as electrodes. For the hydrogen evolution reactions, surface improves the electrolytic cell efficiency [208]. the catalytic activity order is: Pd > Pt ≈ Rh > Ir > Re > Os ≈ Ru > Ni. For the oxygen evolution reactions, Usually, the gas diffusion layer is a titanium plate or porous graphite that have good electrical the order is: Ir ≈ Ru > Pd > Rh > Pt > Au > Nb. The employment of nanoscale composites of catalytic conductivity, mechanical stability and corrosion resistance. In contrast, the separation plate is materials and their homogeneous deposition on the membrane surface improves the electrolytic cell realized with titanium, stainless steel or dense graphite and has to be highly conductive and efficiency [208]. chemically inert [198]. Figure 7. AAsismimplpifliefidedscshcehmemataictiocfoafparoptroontoenxcehxacnhgaenmgeembermanberaenlecetrloeclytrtoiclycteilcl.cReellp.roRdeupcreodufrcoemd f[r2o0m9].[209]. UThsueaellye,cthroecghaesmdiciffaulsrieoanctliaoynesri(sEaqutiattainoinusm(2p2l)a–t(e2o6)r)pocrcoursgornalpyhoitnetthraiptlhe-apvheagsoeobdoeulnecdtarircieasl c(TonPdBus)c,ttivhiatty,amreeacchtaivneicsailtesstaabtilwithyiacnhdthceorgraosidoinffruessiiosntalnacyee.rI,nthceonactrtaivset, cthateaslyepstaarantdiotnheplealteectirsorleyatleizaerde connected. Channels, at the gas diffusion layer, transport water and product gases and conduct electrons for the reaction, at the active layer, reactions are performed, and protons are transported 2H + 2e → H (Overall HER reaction) (22) H + e → H (Volmer step) (23) H + H + e → H (Heyrovsky step)PDF Image | Green Synthetic Fuels

PDF Search Title:

Green Synthetic FuelsOriginal File Name Searched:

energies-13-00420.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |