PDF Publication Title:

Text from PDF Page: 002

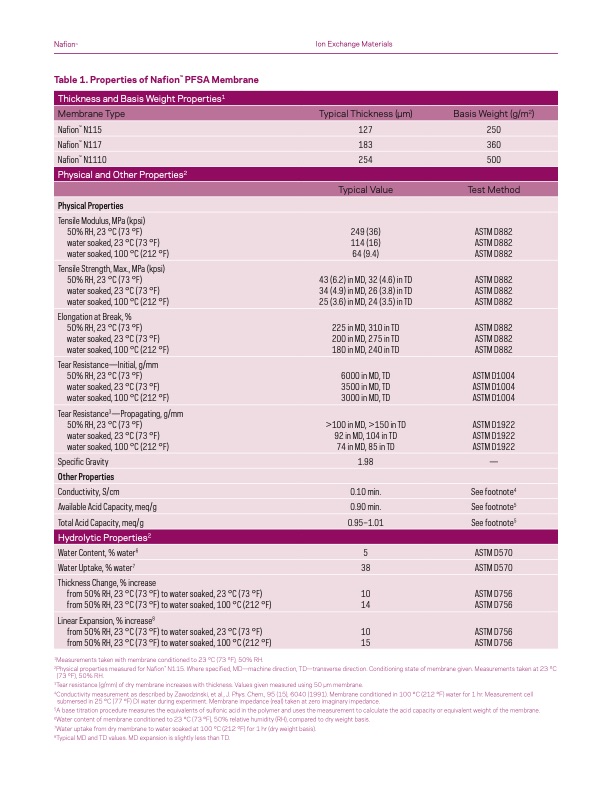

NafionTM Ion Exchange Materials Table 1. Properties of NafionTM PFSA Membrane Thickness and Basis Weight Properties1 Membrane Type Typical Thickness (μm) Basis Weight (g/m2) NafionTM N115 127 250 NafionTM N117 183 360 NafionTM N1110 254 500 Physical and Other Properties2 Typical Value Test Method Physical Properties Tensile Modulus, MPa (kpsi) 50% RH, 23 °C (73 °F) water soaked, 23 °C (73 °F) water soaked, 100 °C (212 °F) 249 (36) 114 (16) 64 (9.4) ASTM D882 ASTM D882 ASTM D882 Tensile Strength, Max., MPa (kpsi) 50% RH, 23 °C (73 °F) water soaked, 23 °C (73 °F) water soaked, 100 °C (212 °F) 43 (6.2) in MD, 32 (4.6) in TD 34 (4.9) in MD, 26 (3.8) in TD 25 (3.6) in MD, 24 (3.5) in TD ASTM D882 ASTM D882 ASTM D882 Elongation at Break, % 50% RH, 23 °C (73 °F) water soaked, 23 °C (73 °F) water soaked, 100 °C (212 °F) 225 in MD, 310 in TD 200 in MD, 275 in TD 180 in MD, 240 in TD ASTM D882 ASTM D882 ASTM D882 Tear Resistance—Initial, g/mm 50% RH, 23 °C (73 °F) water soaked, 23 °C (73 °F) water soaked, 100 °C (212 °F) 6000 in MD, TD 3500 in MD, TD 3000 in MD, TD ASTM D1004 ASTM D1004 ASTM D1004 Tear Resistance3—Propagating, g/mm 50% RH, 23 °C (73 °F) water soaked, 23 °C (73 °F) water soaked, 100 °C (212 °F) >100 in MD, >150 in TD 92 in MD, 104 in TD 74 in MD, 85 in TD ASTM D1922 ASTM D1922 ASTM D1922 Specific Gravity 1.98 — Other Properties Conductivity, S/cm 0.10 min. See footnote4 Available Acid Capacity, meq/g 0.90 min. See footnote5 Total Acid Capacity, meq/g 0.95–1.01 See footnote5 Hydrolytic Properties2 Water Content, % water6 5 ASTM D570 Water Uptake, % water7 38 ASTM D570 Thickness Change, % increase from 50% RH, 23 °C (73 °F) to water soaked, 23 °C (73 °F) from 50% RH, 23 °C (73 °F) to water soaked, 100 °C (212 °F) 10 14 ASTM D756 ASTM D756 Linear Expansion, % increase8 from 50% RH, 23 °C (73 °F) to water soaked, 23 °C (73 °F) from 50% RH, 23 °C (73 °F) to water soaked, 100 °C (212 °F) 10 15 ASTM D756 ASTM D756 1Measurements taken with membrane conditioned to 23 °C (73 °F), 50% RH. 2Physical properties measured for NafionTM N115. Where specified, MD—machine direction, TD—transverse direction. Conditioning state of membrane given. Measurements taken at 23 °C (73 °F), 50% RH. 3Tear resistance (g/mm) of dry membrane increases with thickness. Values given measured using 50 μm membrane. 4Conductivity measurement as described by Zawodzinski, et al., J. Phys. Chem., 95 (15), 6040 (1991). Membrane conditioned in 100 °C (212 °F) water for 1 hr. Measurement cell submersed in 25 °C (77 °F) DI water during experiment. Membrane impedance (real) taken at zero imaginary impedance. 5A base titration procedure measures the equivalents of sulfonic acid in the polymer and uses the measurement to calculate the acid capacity or equivalent weight of the membrane. 6Water content of membrane conditioned to 23 °C (73 °F), 50% relative humidity (RH), compared to dry weight basis. 7Water uptake from dry membrane to water soaked at 100 °C (212 °F) for 1 hr (dry weight basis). 8Typical MD and TD values. MD expansion is slightly less than TD.PDF Image | Ion Exchange Materials Extrusion Cast Membranes

PDF Search Title:

Ion Exchange Materials Extrusion Cast MembranesOriginal File Name Searched:

chemours-nafion-115-117-1110-spec-sheet.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |