PDF Publication Title:

Text from PDF Page: 003

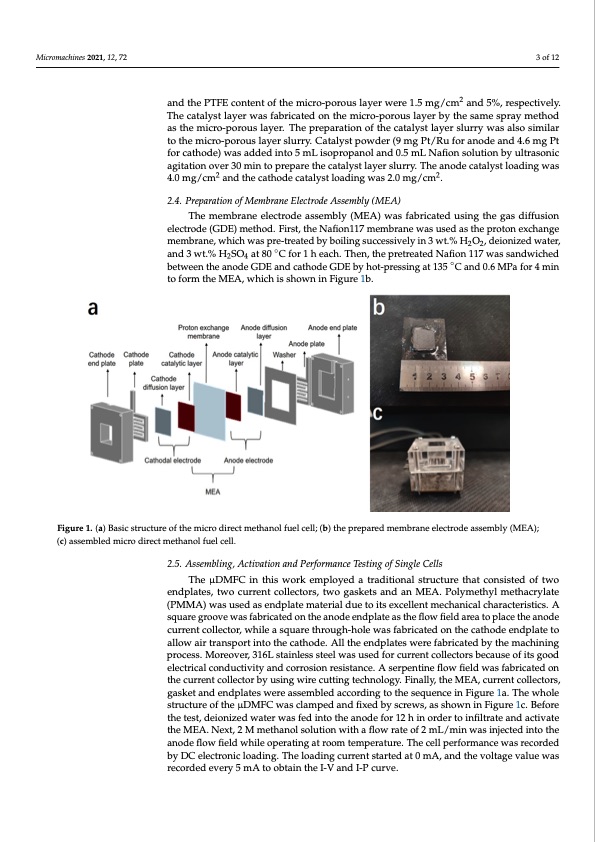

5 mL isopropanol for 0.5 h to form a catalytic layer slurry. Micromachines 2021, 12, 72 2.3. Preparation of Electrode The electrode of μDMFC mainly includes the diffusion layer and the catalyst layer. In this work, carbon papers with a size of 15 × 15 mm were prepared as the base of the diffusion layer. A micro-porous layer was fabricated on the carbon paper by the slurry spray method. The micro-porous layer slurry was prepared by dissolving 3.5 mg of carbon powder into 2 mL isopropanol and 0.5 mL PTFE emulsion. After ultrasonic agitation for 30 min, the micro-porous layer slurry could be prepared for use. The carbon loading and 3 of 12 and the PTFE content of the micro-porous layer were 1.25 mg/cm2 and 5%, respectively. the PTFE content of the micro-porous layer were 1.5 mg/cm and 5%, respectively. The The catalyst layer was fabricated on the micro-porous layer by the same spray method catalyst layer was fabricated on the micro-porous layer by the same spray method as the asmtihcreo-mpoicrorou-sploayroeru.sTlhaeyper.epTahraetiporneopfatrhaeticoantaolyfsthleayceartasluyrsrtylawyaesraslsluorsriymiwlaarstoaltshoe similar tomtihcreom-piocrroou-sploayroeruslularryye.rCsaltuarlyryst.pCoawtadleyrs(t9pmogwPdt/eRru(9fomragnoPdt/eRanudf4o.r6amngoPdtefoarncdat4h.-6mgPt ode) was added into 5 mL isopropanol and 0.5 mL Nafion solution by ultrasonic agitation for cathode) was added into 5 mL isopropanol and 0.5 mL Nafion solution by ultrasonic over 30 min to prepare the catalyst layer slurry. The anode catalyst loading was 4.0 agitation over 30 min to prepare the catalyst layer slurry. The anode catalyst loading was mg/cm2 and2 the cathode catalyst loading was 2.0 mg/cm2. 2 4.0mg/cm andthecathodecatalystloadingwas2.0mg/cm. 2.4. Preparation of Membrane Electrode Assembly (MEA) 2.4. Preparation of Membrane Electrode Assembly (MEA) The membrane electrode assembly (MEA) was fabricated using the gas diffusion The membrane electrode assembly (MEA) was fabricated using the gas diffusion electrode (GDE) method. First, the Nafion117 membrane was used as the proton exchange electrode (GDE) method. First, the Nafion117 membrane was used as the proton exchange membrane, which was pre-treated by boiling successively in 3 wt.% H2O2, deionized wa- membrane, which was pre-treated by boiling successively in 3 wt.% H2O2, deionized water, ter, and 3 wt.% H2SO4 at 80 °C for 1 h each. Then, the pretreated Nafion 117 was sand- and 3 wt.% H2SO4 at 80 ◦C for 1 h each. Then, the pretreated Nafion 117 was sandwiched wiched between the anode GDE and cathode GDE by hot-pressing at 135 °C and 0.6 MPa between the anode GDE and cathode GDE by hot-pressing at 135 ◦C and 0.6 MPa for 4 min for 4 min to form the MEA, which is shown in Figure 1b. to form the MEA, which is shown in Figure 1b. Figure 1. (a) Basic structure of the micro direct methanol fuel cell; (b) the prepared membrane electrode assembly (MEA); Figure 1. (a) Basic structure of the micro direct methanol fuel cell; (b) the prepared membrane electrode assembly (MEA); (c) assembled micro direct methanol fuel cell. (c) assembled micro direct methanol fuel cell. 2.5. Assembling, Activation and Performance Testing of Single Cells 2.5. Assembling, Activation and Performance Testing of Single Cells The μDMFC in this work employed a traditional structure that consisted of two end- The μDMFC in this work employed a traditional structure that consisted of two plates, two current collectors, two gaskets and an MEA. Polymethyl methacrylate endplates, two current collectors, two gaskets and an MEA. Polymethyl methacrylate (PMMA) was used as endplate material due to its excellent mechanical characteristics. A (PMMA) was used as endplate material due to its excellent mechanical characteristics. A square groove was fabricated on the anode endplate as the flow field area to place the anode current collector, while a square through-hole was fabricated on the cathode endplate to allow air transport into the cathode. All the endplates were fabricated by the machining process. Moreover, 316L stainless steel was used for current collectors because of its good electrical conductivity and corrosion resistance. A serpentine flow field was fabricated on the current collector by using wire cutting technology. Finally, the MEA, current collectors, gasket and endplates were assembled according to the sequence in Figure 1a. The whole structure of the μDMFC was clamped and fixed by screws, as shown in Figure 1c. Before the test, deionized water was fed into the anode for 12 h in order to infiltrate and activate the MEA. Next, 2 M methanol solution with a flow rate of 2 mL/min was injected into the anode flow field while operating at room temperature. The cell performance was recorded by DC electronic loading. The loading current started at 0 mA, and the voltage value was recorded every 5 mA to obtain the I-V and I-P curve.PDF Image | Micro Direct Methanol Fuel Cell Reduced Graphene Oxide

PDF Search Title:

Micro Direct Methanol Fuel Cell Reduced Graphene OxideOriginal File Name Searched:

micromachines-12-00072-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |