PDF Publication Title:

Text from PDF Page: 009

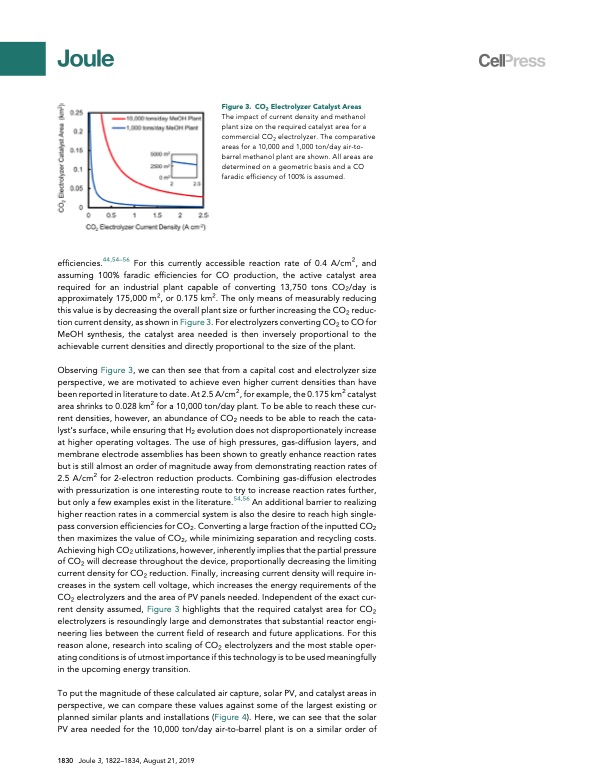

Figure 3. CO2 Electrolyzer Catalyst Areas The impact of current density and methanol plant size on the required catalyst area for a commercial CO2 electrolyzer. The comparative areas for a 10,000 and 1,000 ton/day air-to- barrel methanol plant are shown. All areas are determined on a geometric basis and a CO faradic efficiency of 100% is assumed. efficiencies.44,54–56 For this currently accessible reaction rate of 0.4 A/cm2, and assuming 100% faradic efficiencies for CO production, the active catalyst area required for an industrial plant capable of converting 13,750 tons CO2/day is approximately 175,000 m2, or 0.175 km2. The only means of measurably reducing this value is by decreasing the overall plant size or further increasing the CO2 reduc- tion current density, as shown in Figure 3. For electrolyzers converting CO2 to CO for MeOH synthesis, the catalyst area needed is then inversely proportional to the achievable current densities and directly proportional to the size of the plant. Observing Figure 3, we can then see that from a capital cost and electrolyzer size perspective, we are motivated to achieve even higher current densities than have been reported in literature to date. At 2.5 A/cm2, for example, the 0.175 km2 catalyst area shrinks to 0.028 km2 for a 10,000 ton/day plant. To be able to reach these cur- rent densities, however, an abundance of CO2 needs to be able to reach the cata- lyst’s surface, while ensuring that H2 evolution does not disproportionately increase at higher operating voltages. The use of high pressures, gas-diffusion layers, and membrane electrode assemblies has been shown to greatly enhance reaction rates but is still almost an order of magnitude away from demonstrating reaction rates of 2.5 A/cm2 for 2-electron reduction products. Combining gas-diffusion electrodes with pressurization is one interesting route to try to increase reaction rates further, but only a few examples exist in the literature.54,56 An additional barrier to realizing higher reaction rates in a commercial system is also the desire to reach high single- pass conversion efficiencies for CO2. Converting a large fraction of the inputted CO2 then maximizes the value of CO2, while minimizing separation and recycling costs. Achieving high CO2 utilizations, however, inherently implies that the partial pressure of CO2 will decrease throughout the device, proportionally decreasing the limiting current density for CO2 reduction. Finally, increasing current density will require in- creases in the system cell voltage, which increases the energy requirements of the CO2 electrolyzers and the area of PV panels needed. Independent of the exact cur- rent density assumed, Figure 3 highlights that the required catalyst area for CO2 electrolyzers is resoundingly large and demonstrates that substantial reactor engi- neering lies between the current field of research and future applications. For this reason alone, research into scaling of CO2 electrolyzers and the most stable oper- ating conditions is of utmost importance if this technology is to be used meaningfully in the upcoming energy transition. To put the magnitude of these calculated air capture, solar PV, and catalyst areas in perspective, we can compare these values against some of the largest existing or planned similar plants and installations (Figure 4). Here, we can see that the solar PV area needed for the 10,000 ton/day air-to-barrel plant is on a similar order of 1830 Joule 3, 1822–1834, August 21, 2019PDF Image | Pathways to Industrial Scale Fuel from CO2 Electrolysis

PDF Search Title:

Pathways to Industrial Scale Fuel from CO2 ElectrolysisOriginal File Name Searched:

PIIS2542435119303538.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |