PDF Publication Title:

Text from PDF Page: 003

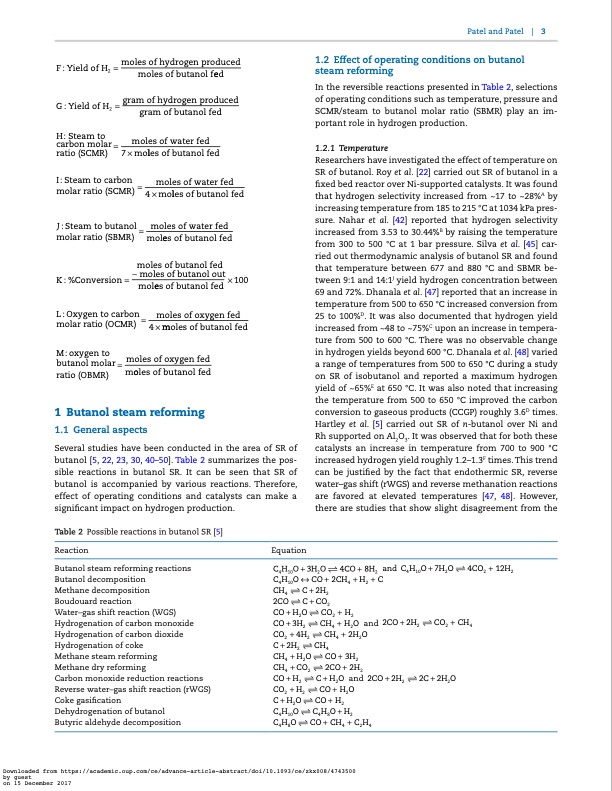

F : Yield of H = moles of hydrogen produced 2 moles of butanol fed G:YieldofH2 =gramofhydrogenproduced gram of butanol fed Patel and Patel | 3 1.2 Effect of operating conditions on butanol steam reforming In the reversible reactions presented in Table 2, selections of operating conditions such as temperature, pressure and SCMR/steam to butanol molar ratio (SBMR) play an im- portant role in hydrogen production. 1.2.1 Temperature Researchers have investigated the effect of temperature on SR of butanol. Roy et al. [22] carried out SR of butanol in a fixed bed reactor over Ni-supported catalysts. It was found that hydrogen selectivity increased from ~17 to ~28%A by increasing temperature from 185 to 215 °C at 1034 kPa pres- sure. Nahar et al. [42] reported that hydrogen selectivity increased from 3.53 to 30.44%B by raising the temperature from 300 to 500 °C at 1 bar pressure. Silva et al. [45] car- ried out thermodynamic analysis of butanol SR and found that temperature between 677 and 880 °C and SBMR be- tween 9:1 and 14:1J yield hydrogen concentration between 69 and 72%. Dhanala et al. [47] reported that an increase in temperature from 500 to 650 °C increased conversion from 25 to 100%D. It was also documented that hydrogen yield increased from ~48 to ~75%C upon an increase in tempera- ture from 500 to 600 °C. There was no observable change in hydrogen yields beyond 600 °C. Dhanala et al. [48] varied a range of temperatures from 500 to 650 °C during a study on SR of isobutanol and reported a maximum hydrogen yield of ~65%E at 650 °C. It was also noted that increasing the temperature from 500 to 650 °C improved the carbon conversion to gaseous products (CCGP) roughly 3.6D times. Hartley et al. [5] carried out SR of n-butanol over Ni and Rh supported on Al2O3. It was observed that for both these catalysts an increase in temperature from 700 to 900 °C increased hydrogen yield roughly 1.2–1.3F times. This trend can be justified by the fact that endothermic SR, reverse water–gas shift (rWGS) and reverse methanation reactions are favored at elevated temperatures [47, 48]. However, there are studies that show slight disagreement from the Equation C4H10O + 3H2O 4CO + 8H2 and C4H10O + 7H2O 4CO2 + 12H2 C4H10O↔CO+2CH4 +H2 +C CH4 C+2H2 2COC+CO2 CO+H2OCO2 + H2 CO+3H2 CH4 + H2O and 2CO+2H2 CO2 + CH4 CO2 +4H2 CH4 +2H2O C+2H2 CH4 CH4 +H2OCO+ 3H2 CH4 +CO2 2CO+ 2H2 CO+H2 C+H2O and 2CO+2H2 2C+2H2O CO2 +H2 CO+ H2O C+H2OCO+ H2 C4H10O C4H8O + H2 C4H8O CO + CH4 + C2H4 H: Steam to carbon molar = ratio (SCMR) moles of water fed 7 × moles of butanol fed I : Steam to carbon molar ratio (SCMR) = moles of water fed molar ratio (SBMR) = moles of butanol fed moles of butanol fed K : %Conversion = − moles of butanol out × 100 moles of butanol fed L : Oxygen to carbon = moles of oxygen fed molar ratio (OCMR) 4 × moles of butanol fed J : Steam to butanol moles of water fed 4 × moles of butanol fed M : oxygen to moles of oxygen fed butanol molar = moles of butanol fed ratio (OBMR) 1 Butanol steam reforming 1.1 General aspects Several studies have been conducted in the area of SR of butanol [5, 22, 23, 30, 40–50]. Table 2 summarizes the pos- sible reactions in butanol SR. It can be seen that SR of butanol is accompanied by various reactions. Therefore, effect of operating conditions and catalysts can make a significant impact on hydrogen production. Table 2 Possible reactions in butanol SR [5] Reaction Butanol steam reforming reactions Butanol decomposition Methane decomposition Boudouard reaction Water–gas shift reaction (WGS) Hydrogenation of carbon monoxide Hydrogenation of carbon dioxide Hydrogenation of coke Methane steam reforming Methane dry reforming Carbon monoxide reduction reactions Reverse water–gas shift reaction (rWGS) Coke gasification Dehydrogenation of butanol Butyric aldehyde decomposition Downloaded from https://academic.oup.com/ce/advance-article-abstract/doi/10.1093/ce/zkx008/4743500 by guest on 15 December 2017PDF Image | Renewable hydrogen production from butanol

PDF Search Title:

Renewable hydrogen production from butanolOriginal File Name Searched:

Renewable_hydrogen_production_from_butanol.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |