PDF Publication Title:

Text from PDF Page: 042

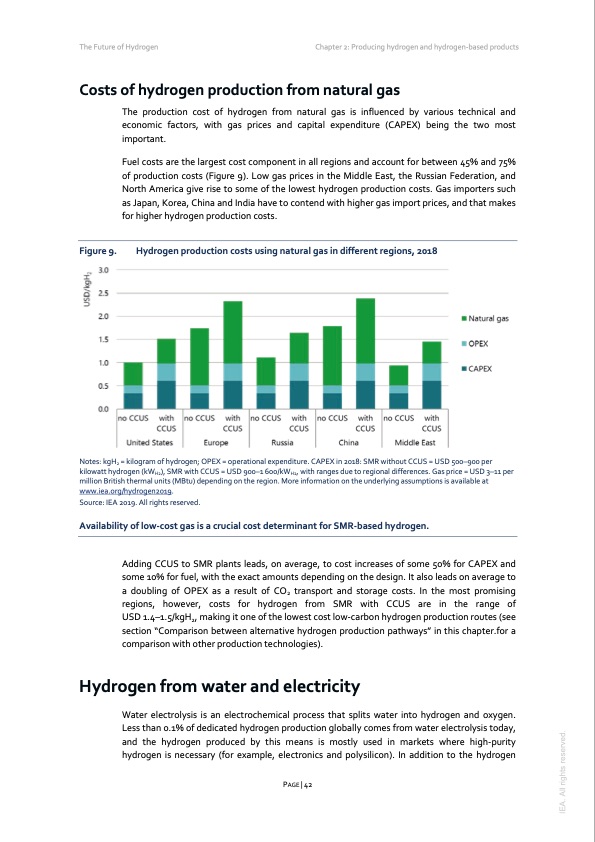

The Future of Hydrogen Chapter 2: Producing hydrogen and hydrogen-based products Costs of hydrogen production from natural gas Figure 9. The production cost of hydrogen from natural gas is influenced by various technical and economic factors, with gas prices and capital expenditure (CAPEX) being the two most important. Fuel costs are the largest cost component in all regions and account for between 45% and 75% of production costs (Figure 9). Low gas prices in the Middle East, the Russian Federation, and North America give rise to some of the lowest hydrogen production costs. Gas importers such as Japan, Korea, China and India have to contend with higher gas import prices, and that makes for higher hydrogen production costs. Hydrogen production costs using natural gas in different regions, 2018 Notes: kgH2 = kilogram of hydrogen; OPEX = operational expenditure. CAPEX in 2018: SMR without CCUS = USD 500–900 per kilowatt hydrogen (kWH2), SMR with CCUS = USD 900–1 600/kWH2, with ranges due to regional differences. Gas price = USD 3–11 per million British thermal units (MBtu) depending on the region. More information on the underlying assumptions is available at www.iea.org/hydrogen2019. Source: IEA 2019. All rights reserved. Availability of low-cost gas is a crucial cost determinant for SMR-based hydrogen. Adding CCUS to SMR plants leads, on average, to cost increases of some 50% for CAPEX and some 10% for fuel, with the exact amounts depending on the design. It also leads on average to a doubling of OPEX as a result of CO2 transport and storage costs. In the most promising regions, however, costs for hydrogen from SMR with CCUS are in the range of USD 1.4–1.5/kgH2, making it one of the lowest cost low-carbon hydrogen production routes (see section “Comparison between alternative hydrogen production pathways” in this chapter.for a comparison with other production technologies). Hydrogen from water and electricity Water electrolysis is an electrochemical process that splits water into hydrogen and oxygen. Less than 0.1% of dedicated hydrogen production globally comes from water electrolysis today, and the hydrogen produced by this means is mostly used in markets where high-purity hydrogen is necessary (for example, electronics and polysilicon). In addition to the hydrogen PAGE | 42 IEA. All rights reserved.PDF Image | The Future of Hydrogen 2019

PDF Search Title:

The Future of Hydrogen 2019Original File Name Searched:

the_future_of_hydrogen.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |