PDF Publication Title:

Text from PDF Page: 044

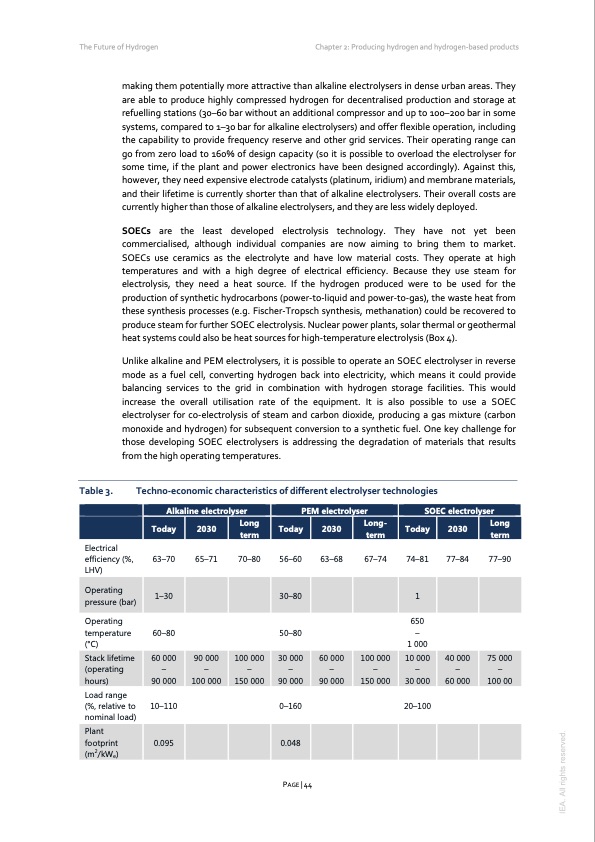

The Future of Hydrogen Chapter 2: Producing hydrogen and hydrogen-based products making them potentially more attractive than alkaline electrolysers in dense urban areas. They are able to produce highly compressed hydrogen for decentralised production and storage at refuelling stations (30–60 bar without an additional compressor and up to 100–200 bar in some systems, compared to 1–30 bar for alkaline electrolysers) and offer flexible operation, including the capability to provide frequency reserve and other grid services. Their operating range can go from zero load to 160% of design capacity (so it is possible to overload the electrolyser for some time, if the plant and power electronics have been designed accordingly). Against this, however, they need expensive electrode catalysts (platinum, iridium) and membrane materials, and their lifetime is currently shorter than that of alkaline electrolysers. Their overall costs are currently higher than those of alkaline electrolysers, and they are less widely deployed. SOECs are the least developed electrolysis technology. They have not yet been commercialised, although individual companies are now aiming to bring them to market. SOECs use ceramics as the electrolyte and have low material costs. They operate at high temperatures and with a high degree of electrical efficiency. Because they use steam for electrolysis, they need a heat source. If the hydrogen produced were to be used for the production of synthetic hydrocarbons (power-to-liquid and power-to-gas), the waste heat from these synthesis processes (e.g. Fischer-Tropsch synthesis, methanation) could be recovered to produce steam for further SOEC electrolysis. Nuclear power plants, solar thermal or geothermal heat systems could also be heat sources for high-temperature electrolysis (Box 4). Unlike alkaline and PEM electrolysers, it is possible to operate an SOEC electrolyser in reverse mode as a fuel cell, converting hydrogen back into electricity, which means it could provide balancing services to the grid in combination with hydrogen storage facilities. This would increase the overall utilisation rate of the equipment. It is also possible to use a SOEC electrolyser for co-electrolysis of steam and carbon dioxide, producing a gas mixture (carbon monoxide and hydrogen) for subsequent conversion to a synthetic fuel. One key challenge for those developing SOEC electrolysers is addressing the degradation of materials that results from the high operating temperatures. Techno-economic characteristics of different electrolyser technologies Table 3. Electrical efficiency (%, LHV) Operating temperature (°C) Load range (%, relative to nominal load) 63–70 60–80 10–110 65–71 70–80 56–60 50–80 0–160 63–68 67–74 74–81 650 – 1 000 20–100 77–84 77–90 Alkaline electrolyser PEM electrolyser SOEC electrolyser Today 2030 Long term Today 2030 Long- term Today 2030 Long term Operating pressure (bar) 1–30 30–80 1 Stack lifetime (operating hours) 60 000 – 90 000 90 000 – 100 000 100 000 – 150 000 30 000 – 90 000 60 000 – 90 000 100 000 – 150 000 10 000 – 30 000 40 000 – 60 000 75 000 – 100 00 Plant footprint (m2/kWe) 0.095 0.048 PAGE | 44 IEA. All rights reserved.PDF Image | The Future of Hydrogen 2019

PDF Search Title:

The Future of Hydrogen 2019Original File Name Searched:

the_future_of_hydrogen.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |