PDF Publication Title:

Text from PDF Page: 013

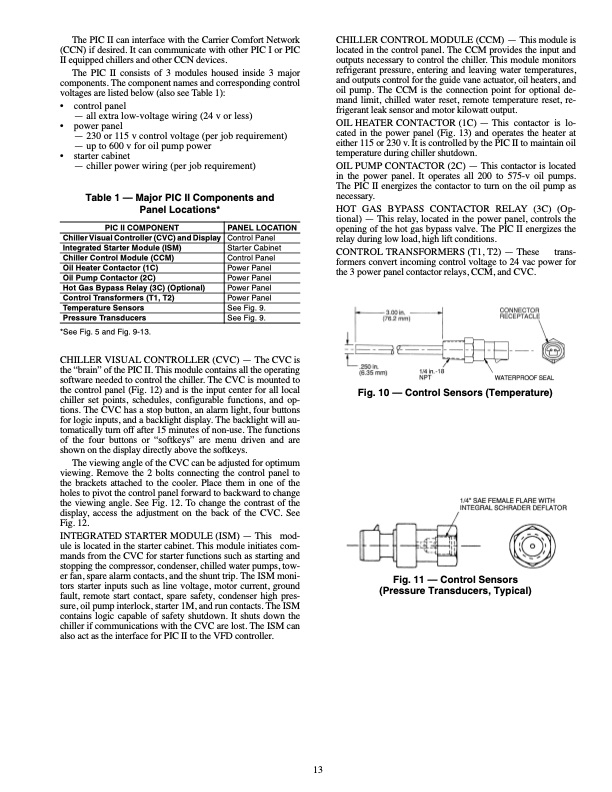

The PIC II can interface with the Carrier Comfort Network (CCN) if desired. It can communicate with other PIC I or PIC II equipped chillers and other CCN devices. The PIC II consists of 3 modules housed inside 3 major components. The component names and corresponding control voltages are listed below (also see Table 1): • control panel — all extra low-voltage wiring (24 v or less) • power panel — 230 or 115 v control voltage (per job requirement) — up to 600 v for oil pump power • starter cabinet — chiller power wiring (per job requirement) Table 1 — Major PIC II Components and Panel Locations* CHILLER CONTROL MODULE (CCM) — This module is located in the control panel. The CCM provides the input and outputs necessary to control the chiller. This module monitors refrigerant pressure, entering and leaving water temperatures, and outputs control for the guide vane actuator, oil heaters, and oil pump. The CCM is the connection point for optional de- mand limit, chilled water reset, remote temperature reset, re- frigerant leak sensor and motor kilowatt output. OIL HEATER CONTACTOR (1C) — This contactor is lo- cated in the power panel (Fig. 13) and operates the heater at either 115 or 230 v. It is controlled by the PIC II to maintain oil temperature during chiller shutdown. OIL PUMP CONTACTOR (2C) — This contactor is located in the power panel. It operates all 200 to 575-v oil pumps. The PIC II energizes the contactor to turn on the oil pump as necessary. HOT GAS BYPASS CONTACTOR RELAY (3C) (Op- tional) — This relay, located in the power panel, controls the opening of the hot gas bypass valve. The PIC II energizes the relay during low load, high lift conditions. CONTROL TRANSFORMERS (T1, T2) — These trans- formers convert incoming control voltage to 24 vac power for the 3 power panel contactor relays, CCM, and CVC. Fig. 10 — Control Sensors (Temperature) PIC II COMPONENT Chiller Visual Controller (CVC) and Display Integrated Starter Module (ISM) Chiller Control Module (CCM) Oil Heater Contactor (1C) Oil Pump Contactor (2C) Hot Gas Bypass Relay (3C) (Optional) Control Transformers (T1, T2) Temperature Sensors Pressure Transducers *See Fig. 5 and Fig. 9-13. PANEL LOCATION Control Panel Starter Cabinet Control Panel Power Panel Power Panel Power Panel Power Panel See Fig. 9. See Fig. 9. CHILLER VISUAL CONTROLLER (CVC) — The CVC is the “brain” of the PIC II. This module contains all the operating software needed to control the chiller. The CVC is mounted to the control panel (Fig. 12) and is the input center for all local chiller set points, schedules, configurable functions, and op- tions. The CVC has a stop button, an alarm light, four buttons for logic inputs, and a backlight display. The backlight will au- tomatically turn off after 15 minutes of non-use. The functions of the four buttons or “softkeys” are menu driven and are shown on the display directly above the softkeys. The viewing angle of the CVC can be adjusted for optimum viewing. Remove the 2 bolts connecting the control panel to the brackets attached to the cooler. Place them in one of the holes to pivot the control panel forward to backward to change the viewing angle. See Fig. 12. To change the contrast of the display, access the adjustment on the back of the CVC. See Fig. 12. INTEGRATED STARTER MODULE (ISM) — This mod- ule is located in the starter cabinet. This module initiates com- mands from the CVC for starter functions such as starting and stopping the compressor, condenser, chilled water pumps, tow- er fan, spare alarm contacts, and the shunt trip. The ISM moni- tors starter inputs such as line voltage, motor current, ground fault, remote start contact, spare safety, condenser high pres- sure, oil pump interlock, starter 1M, and run contacts. The ISM contains logic capable of safety shutdown. It shuts down the chiller if communications with the CVC are lost. The ISM can also act as the interface for PIC II to the VFD controller. Fig. 11 — Control Sensors (Pressure Transducers, Typical) 13PDF Image | 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a

PDF Search Title:

19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134aOriginal File Name Searched:

19xr_4ss_Startup_PICII.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |