PDF Publication Title:

Text from PDF Page: 059

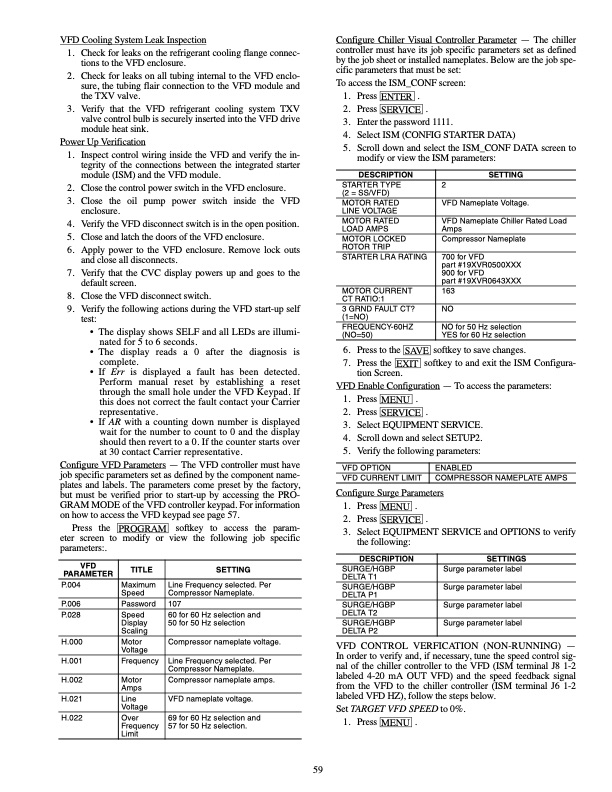

VFD Cooling System Leak Inspection 1. Check for leaks on the refrigerant cooling flange connec- tions to the VFD enclosure. 2. Check for leaks on all tubing internal to the VFD enclo- sure, the tubing flair connection to the VFD module and the TXV valve. 3. Verify that the VFD refrigerant cooling system TXV valve control bulb is securely inserted into the VFD drive module heat sink. Power Up Verification 1. Inspect control wiring inside the VFD and verify the in- tegrity of the connections between the integrated starter module (ISM) and the VFD module. 2. Close the control power switch in the VFD enclosure. 3. Close the oil pump power switch inside the VFD enclosure. 4. Verify the VFD disconnect switch is in the open position. 5. Close and latch the doors of the VFD enclosure. 6. Apply power to the VFD enclosure. Remove lock outs and close all disconnects. 7. Verify that the CVC display powers up and goes to the default screen. 8. Close the VFD disconnect switch. 9. Verify the following actions during the VFD start-up self test: • The display shows SELF and all LEDs are illumi- nated for 5 to 6 seconds. • The display reads a 0 after the diagnosis is complete. • If Err is displayed a fault has been detected. Perform manual reset by establishing a reset through the small hole under the VFD Keypad. If this does not correct the fault contact your Carrier representative. • If AR with a counting down number is displayed wait for the number to count to 0 and the display should then revert to a 0. If the counter starts over at 30 contact Carrier representative. Configure VFD Parameters — The VFD controller must have job specific parameters set as defined by the component name- plates and labels. The parameters come preset by the factory, but must be verified prior to start-up by accessing the PRO- GRAM MODE of the VFD controller keypad. For information on how to access the VFD keypad see page 57. Press the PROGRAM softkey to access the param- eter screen to modify or view the following job specific parameters:. VFD PARAMETER Configure Chiller Visual Controller Parameter — The chiller controller must have its job specific parameters set as defined by the job sheet or installed nameplates. Below are the job spe- cific parameters that must be set: To access the ISM_CONF screen: 1. Press ENTER . 2. Press SERVICE . 3. Enter the password 1111. 4. Select ISM (CONFIG STARTER DATA) 5. Scroll down and select the ISM_CONF DATA screen to modify or view the ISM parameters: DESCRIPTION STARTER TYPE (2 = SS/VFD) MOTOR RATED LINE VOLTAGE MOTOR RATED LOAD AMPS MOTOR LOCKED ROTOR TRIP STARTER LRA RATING MOTOR CURRENT CT RATIO:1 3 GRND FAULT CT? (1=NO) FREQUENCY-60HZ (NO=50) SETTING 2 VFD Nameplate Voltage. VFD Nameplate Chiller Rated Load Amps Compressor Nameplate 700 for VFD part #19XVR0500XXX 900 for VFD part #19XVR0643XXX 163 NO NO for 50 Hz selection YES for 60 Hz selection 6. Press to the SAVE softkey to save changes. 7. Press the EXIT softkey to and exit the ISM Configura- tion Screen. VFD Enable Configuration — To access the parameters: 1. Press MENU . 2. Press SERVICE . 3. Select EQUIPMENT SERVICE. 4. Scroll down and select SETUP2. 5. Verify the following parameters: VFD OPTION ENABLED VFD CURRENT LIMIT COMPRESSOR NAMEPLATE AMPS Configure Surge Parameters 1. Press MENU . 2. Press SERVICE . 3. Select EQUIPMENT SERVICE and OPTIONS to verify the following: TITLE Maximum Speed Password Speed Display Scaling Motor Voltage Frequency Motor Amps Line Voltage Over Frequency Limit P.004 Line Frequency selected. Per Compressor Nameplate. P.006 107 P.028 60 for 60 Hz selection and 50 for 50 Hz selection H.000 Compressor nameplate voltage. H.001 Line Frequency selected. Per Compressor Nameplate. H.002 Compressor nameplate amps. H.021 VFD nameplate voltage. H.022 69 for 60 Hz selection and 57 for 50 Hz selection. VFD CONTROL VERFICATION (NON-RUNNING) — In order to verify and, if necessary, tune the speed control sig- nal of the chiller controller to the VFD (ISM terminal J8 1-2 labeled 4-20 mA OUT VFD) and the speed feedback signal from the VFD to the chiller controller (ISM terminal J6 1-2 labeled VFD HZ), follow the steps below. Set TARGET VFD SPEED to 0%. 1. Press MENU . SETTING DESCRIPTION SURGE/HGBP DELTA T1 SURGE/HGBP DELTA P1 SURGE/HGBP DELTA T2 SURGE/HGBP DELTA P2 SETTINGS Surge parameter label Surge parameter label Surge parameter label Surge parameter label 59PDF Image | 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a

PDF Search Title:

19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134aOriginal File Name Searched:

19xr_4ss_Startup_PICII.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |