PDF Publication Title:

Text from PDF Page: 063

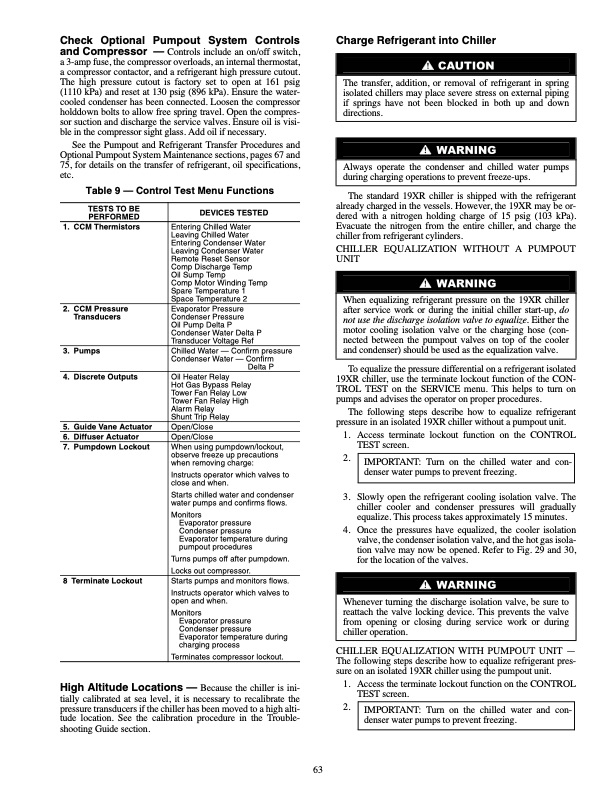

Check Optional Pumpout System Controls and Compressor — Controls include an on/off switch, a 3-amp fuse, the compressor overloads, an internal thermostat, a compressor contactor, and a refrigerant high pressure cutout. The high pressure cutout is factory set to open at 161 psig (1110 kPa) and reset at 130 psig (896 kPa). Ensure the water- cooled condenser has been connected. Loosen the compressor holddown bolts to allow free spring travel. Open the compres- sor suction and discharge the service valves. Ensure oil is visi- ble in the compressor sight glass. Add oil if necessary. See the Pumpout and Refrigerant Transfer Procedures and Optional Pumpout System Maintenance sections, pages 67 and 75, for details on the transfer of refrigerant, oil specifications, etc. Table 9 — Control Test Menu Functions Charge Refrigerant into Chiller The transfer, addition, or removal of refrigerant in spring isolated chillers may place severe stress on external piping if springs have not been blocked in both up and down directions. Always operate the condenser and chilled water pumps during charging operations to prevent freeze-ups. TESTS TO BE PERFORMED 1. CCM Thermistors 2. CCM Pressure Transducers 3. Pumps 4. Discrete Outputs 5. Guide Vane Actuator 6. Diffuser Actuator 7. Pumpdown Lockout DEVICES TESTED Entering Chilled Water Leaving Chilled Water Entering Condenser Water Leaving Condenser Water Remote Reset Sensor Comp Discharge Temp Oil Sump Temp Comp Motor Winding Temp Spare Temperature 1 Space Temperature 2 Evaporator Pressure Condenser Pressure Oil Pump Delta P Condenser Water Delta P Transducer Voltage Ref Chilled Water — Confirm pressure Condenser Water — Confirm Delta P Oil Heater Relay Hot Gas Bypass Relay Tower Fan Relay Low Tower Fan Relay High Alarm Relay Shunt Trip Relay Open/Close Open/Close When using pumpdown/lockout, observe freeze up precautions when removing charge: Instructs operator which valves to close and when. Starts chilled water and condenser water pumps and confirms flows. Monitors Evaporator pressure Condenser pressure Evaporator temperature during pumpout procedures Turns pumps off after pumpdown. Locks out compressor. Starts pumps and monitors flows. Instructs operator which valves to open and when. Monitors Evaporator pressure Condenser pressure Evaporator temperature during charging process Terminates compressor lockout. The standard 19XR chiller is shipped with the refrigerant already charged in the vessels. However, the 19XR may be or- dered with a nitrogen holding charge of 15 psig (103 kPa). Evacuate the nitrogen from the entire chiller, and charge the chiller from refrigerant cylinders. CHILLER EQUALIZATION WITHOUT A PUMPOUT UNIT To equalize the pressure differential on a refrigerant isolated 19XR chiller, use the terminate lockout function of the CON- TROL TEST on the SERVICE menu. This helps to turn on pumps and advises the operator on proper procedures. The following steps describe how to equalize refrigerant pressure in an isolated 19XR chiller without a pumpout unit. 1. Access terminate lockout function on the CONTROL TEST screen. When equalizing refrigerant pressure on the 19XR chiller after service work or during the initial chiller start-up, do not use the discharge isolation valve to equalize. Either the motor cooling isolation valve or the charging hose (con- nected between the pumpout valves on top of the cooler and condenser) should be used as the equalization valve. 2. IMPORTANT: Turn on the chilled water and con- denser water pumps to prevent freezing. 8 Terminate Lockout 3. Slowly open the refrigerant cooling isolation valve. The chiller cooler and condenser pressures will gradually equalize. This process takes approximately 15 minutes. 4. Once the pressures have equalized, the cooler isolation valve, the condenser isolation valve, and the hot gas isola- tion valve may now be opened. Refer to Fig. 29 and 30, for the location of the valves. CHILLER EQUALIZATION WITH PUMPOUT UNIT — The following steps describe how to equalize refrigerant pres- sure on an isolated 19XR chiller using the pumpout unit. 1. Access the terminate lockout function on the CONTROL TEST screen. 2. Whenever turning the discharge isolation valve, be sure to reattach the valve locking device. This prevents the valve from opening or closing during service work or during chiller operation. High Altitude Locations — Because the chiller is ini- tially calibrated at sea level, it is necessary to recalibrate the pressure transducers if the chiller has been moved to a high alti- tude location. See the calibration procedure in the Trouble- shooting Guide section. IMPORTANT: Turn on the chilled water and con- denser water pumps to prevent freezing. 63PDF Image | 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a

PDF Search Title:

19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134aOriginal File Name Searched:

19xr_4ss_Startup_PICII.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |