PDF Publication Title:

Text from PDF Page: 065

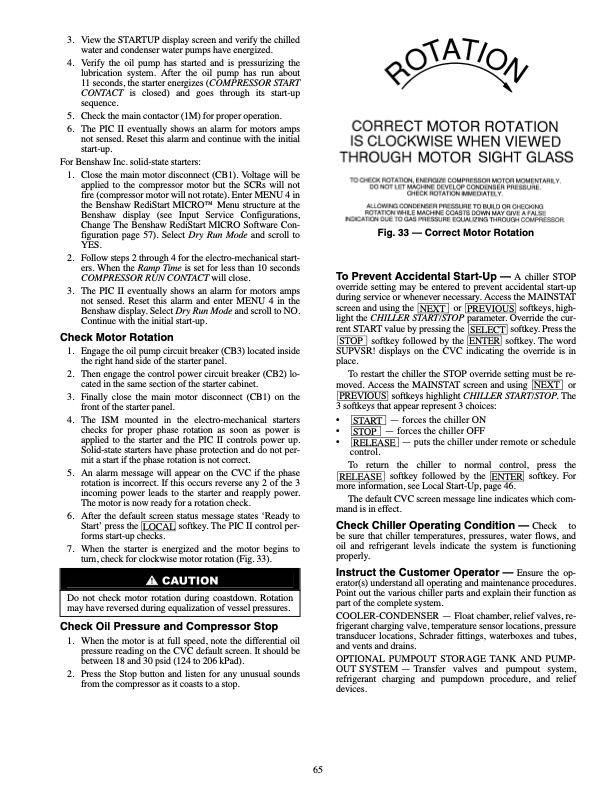

3. View the STARTUP display screen and verify the chilled water and condenser water pumps have energized. 4. Verify the oil pump has started and is pressurizing the lubrication system. After the oil pump has run about 11 seconds, the starter energizes (COMPRESSOR START CONTACT is closed) and goes through its start-up sequence. 5. Check the main contactor (1M) for proper operation. 6. The PIC II eventually shows an alarm for motors amps not sensed. Reset this alarm and continue with the initial start-up. For Benshaw Inc. solid-state starters: 1. Close the main motor disconnect (CB1). Voltage will be applied to the compressor motor but the SCRs will not fire (compressor motor will not rotate). Enter MENU 4 in the Benshaw RediStart MICROTM Menu structure at the Benshaw display (see Input Service Configurations, Change The Benshaw RediStart MICRO Software Con- figuration page 57). Select Dry Run Mode and scroll to YES. 2. Follow steps 2 through 4 for the electro-mechanical start- ers. When the Ramp Time is set for less than 10 seconds COMPRESSOR RUN CONTACT will close. 3. The PIC II eventually shows an alarm for motors amps not sensed. Reset this alarm and enter MENU 4 in the Benshaw display. Select Dry Run Mode and scroll to NO. Continue with the initial start-up. Check Motor Rotation 1. Engage the oil pump circuit breaker (CB3) located inside the right hand side of the starter panel. 2. Then engage the control power circuit breaker (CB2) lo- cated in the same section of the starter cabinet. 3. Finally close the main motor disconnect (CB1) on the front of the starter panel. 4. The ISM mounted in the electro-mechanical starters checks for proper phase rotation as soon as power is applied to the starter and the PIC II controls power up. Solid-state starters have phase protection and do not per- mit a start if the phase rotation is not correct. 5. An alarm message will appear on the CVC if the phase rotation is incorrect. If this occurs reverse any 2 of the 3 incoming power leads to the starter and reapply power. The motor is now ready for a rotation check. 6. After the default screen status message states ‘Ready to Start’ press the LOCAL softkey. The PIC II control per- forms start-up checks. 7. When the starter is energized and the motor begins to turn, check for clockwise motor rotation (Fig. 33). Check Oil Pressure and Compressor Stop 1. When the motor is at full speed, note the differential oil pressure reading on the CVC default screen. It should be between 18 and 30 psid (124 to 206 kPad). 2. Press the Stop button and listen for any unusual sounds from the compressor as it coasts to a stop. Fig. 33 — Correct Motor Rotation To Prevent Accidental Start-Up — A chiller STOP override setting may be entered to prevent accidental start-up during service or whenever necessary. Access the MAINSTAT screen and using the NEXT or PREVIOUS softkeys, high- light the CHILLER START/STOP parameter. Override the cur- rentSTARTvaluebypressingthe SELECT softkey.Pressthe STOP softkey followed by the ENTER softkey. The word SUPVSR! displays on the CVC indicating the override is in place. To restart the chiller the STOP override setting must be re- moved. Access the MAINSTAT screen and using NEXT or PREVIOUS softkeys highlight CHILLER START/STOP. The 3 softkeys that appear represent 3 choices: • • • START — forces the chiller ON STOP — forces the chiller OFF RELEASE —putsthechillerunderremoteorschedule control. To return the chiller to normal control, press the RELEASE softkey followed by the ENTER softkey. For more information, see Local Start-Up, page 46. The default CVC screen message line indicates which com- mand is in effect. Check Chiller Operating Condition — Check to be sure that chiller temperatures, pressures, water flows, and oil and refrigerant levels indicate the system is functioning properly. Instruct the Customer Operator — Ensure the op- erator(s) understand all operating and maintenance procedures. Point out the various chiller parts and explain their function as part of the complete system. COOLER-CONDENSER — Float chamber, relief valves, re- frigerant charging valve, temperature sensor locations, pressure transducer locations, Schrader fittings, waterboxes and tubes, and vents and drains. OPTIONAL PUMPOUT STORAGE TANK AND PUMP- OUT SYSTEM — Transfer valves and pumpout system, refrigerant charging and pumpdown procedure, and relief devices. Do not check motor rotation during coastdown. Rotation may have reversed during equalization of vessel pressures. 65PDF Image | 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a

PDF Search Title:

19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134aOriginal File Name Searched:

19xr_4ss_Startup_PICII.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |