PDF Publication Title:

Text from PDF Page: 004

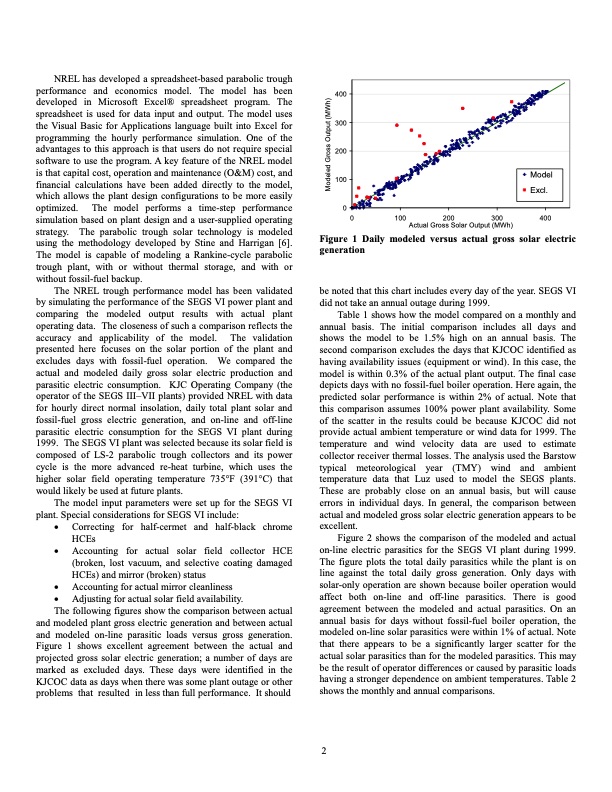

NREL has developed a spreadsheet-based parabolic trough performance and economics model. The model has been developed in Microsoft Excel® spreadsheet program. The spreadsheet is used for data input and output. The model uses the Visual Basic for Applications language built into Excel for programming the hourly performance simulation. One of the advantages to this approach is that users do not require special software to use the program. A key feature of the NREL model is that capital cost, operation and maintenance (O&M) cost, and financial calculations have been added directly to the model, which allows the plant design configurations to be more easily optimized. The model performs a time-step performance simulation based on plant design and a user-supplied operating strategy. The parabolic trough solar technology is modeled using the methodology developed by Stine and Harrigan [6]. The model is capable of modeling a Rankine-cycle parabolic trough plant, with or without thermal storage, and with or without fossil-fuel backup. The NREL trough performance model has been validated by simulating the performance of the SEGS VI power plant and comparing the modeled output results with actual plant operating data. The closeness of such a comparison reflects the accuracy and applicability of the model. The validation presented here focuses on the solar portion of the plant and excludes days with fossil-fuel operation. We compared the actual and modeled daily gross solar electric production and parasitic electric consumption. KJC Operating Company (the operator of the SEGS III–VII plants) provided NREL with data for hourly direct normal insolation, daily total plant solar and fossil-fuel gross electric generation, and on-line and off-line parasitic electric consumption for the SEGS VI plant during 1999. The SEGS VI plant was selected because its solar field is composed of LS-2 parabolic trough collectors and its power cycle is the more advanced re-heat turbine, which uses the higher solar field operating temperature 735°F (391°C) that would likely be used at future plants. The model input parameters were set up for the SEGS VI plant. Special considerations for SEGS VI include: • Correcting for half-cermet and half-black chrome HCEs • Accounting for actual solar field collector HCE (broken, lost vacuum, and selective coating damaged HCEs) and mirror (broken) status • Accounting for actual mirror cleanliness • Adjusting for actual solar field availability. The following figures show the comparison between actual and modeled plant gross electric generation and between actual and modeled on-line parasitic loads versus gross generation. Figure 1 shows excellent agreement between the actual and projected gross solar electric generation; a number of days are marked as excluded days. These days were identified in the KJCOC data as days when there was some plant outage or other problems that resulted in less than full performance. It should 400 300 200 100 0 Model Excl. 0 100 200 Actual Gross Solar Output (MWh) 400 Figure 1 Daily modeled versus actual gross solar electric generation be noted that this chart includes every day of the year. SEGS VI did not take an annual outage during 1999. Table 1 shows how the model compared on a monthly and annual basis. The initial comparison includes all days and shows the model to be 1.5% high on an annual basis. The second comparison excludes the days that KJCOC identified as having availability issues (equipment or wind). In this case, the model is within 0.3% of the actual plant output. The final case depicts days with no fossil-fuel boiler operation. Here again, the predicted solar performance is within 2% of actual. Note that this comparison assumes 100% power plant availability. Some of the scatter in the results could be because KJCOC did not provide actual ambient temperature or wind data for 1999. The temperature and wind velocity data are used to estimate collector receiver thermal losses. The analysis used the Barstow typical meteorological year (TMY) wind and ambient temperature data that Luz used to model the SEGS plants. These are probably close on an annual basis, but will cause errors in individual days. In general, the comparison between actual and modeled gross solar electric generation appears to be excellent. Figure 2 shows the comparison of the modeled and actual on-line electric parasitics for the SEGS VI plant during 1999. The figure plots the total daily parasitics while the plant is on line against the total daily gross generation. Only days with solar-only operation are shown because boiler operation would affect both on-line and off-line parasitics. There is good agreement between the modeled and actual parasitics. On an annual basis for days without fossil-fuel boiler operation, the modeled on-line solar parasitics were within 1% of actual. Note that there appears to be a significantly larger scatter for the actual solar parasitics than for the modeled parasitics. This may be the result of operator differences or caused by parasitic loads having a stronger dependence on ambient temperatures. Table 2 shows the monthly and annual comparisons. 2 300 Modeled Gross Output (MWh)PDF Image | A Parabolic Trough Solar Power Plant Simulation Model

PDF Search Title:

A Parabolic Trough Solar Power Plant Simulation ModelOriginal File Name Searched:

33209.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |