PDF Publication Title:

Text from PDF Page: 007

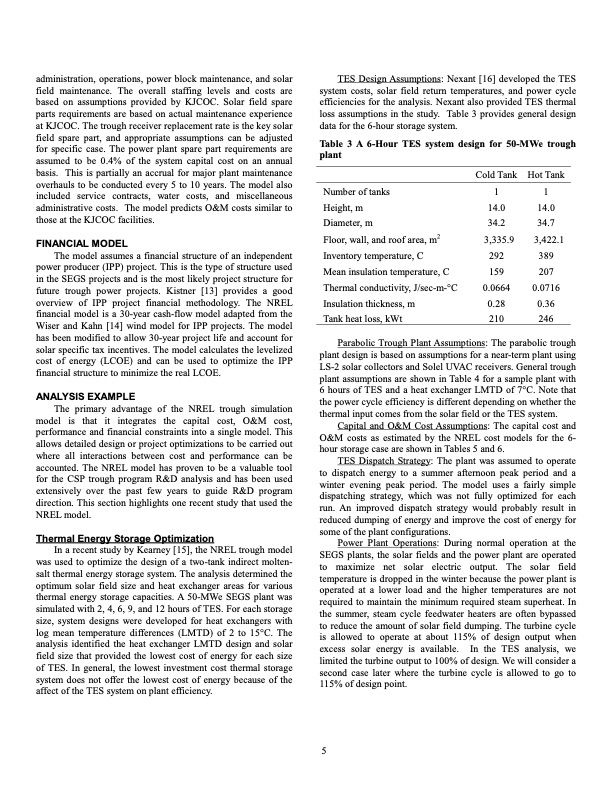

administration, operations, power block maintenance, and solar field maintenance. The overall staffing levels and costs are based on assumptions provided by KJCOC. Solar field spare parts requirements are based on actual maintenance experience at KJCOC. The trough receiver replacement rate is the key solar field spare part, and appropriate assumptions can be adjusted for specific case. The power plant spare part requirements are assumed to be 0.4% of the system capital cost on an annual basis. This is partially an accrual for major plant maintenance overhauls to be conducted every 5 to 10 years. The model also included service contracts, water costs, and miscellaneous administrative costs. The model predicts O&M costs similar to those at the KJCOC facilities. FINANCIAL MODEL The model assumes a financial structure of an independent power producer (IPP) project. This is the type of structure used in the SEGS projects and is the most likely project structure for future trough power projects. Kistner [13] provides a good overview of IPP project financial methodology. The NREL financial model is a 30-year cash-flow model adapted from the Wiser and Kahn [14] wind model for IPP projects. The model has been modified to allow 30-year project life and account for solar specific tax incentives. The model calculates the levelized cost of energy (LCOE) and can be used to optimize the IPP financial structure to minimize the real LCOE. ANALYSIS EXAMPLE The primary advantage of the NREL trough simulation model is that it integrates the capital cost, O&M cost, performance and financial constraints into a single model. This allows detailed design or project optimizations to be carried out where all interactions between cost and performance can be accounted. The NREL model has proven to be a valuable tool for the CSP trough program R&D analysis and has been used extensively over the past few years to guide R&D program direction. This section highlights one recent study that used the NREL model. Thermal Energy Storage Optimization In a recent study by Kearney [15], the NREL trough model was used to optimize the design of a two-tank indirect molten- salt thermal energy storage system. The analysis determined the optimum solar field size and heat exchanger areas for various thermal energy storage capacities. A 50-MWe SEGS plant was simulated with 2, 4, 6, 9, and 12 hours of TES. For each storage size, system designs were developed for heat exchangers with log mean temperature differences (LMTD) of 2 to 15°C. The analysis identified the heat exchanger LMTD design and solar field size that provided the lowest cost of energy for each size of TES. In general, the lowest investment cost thermal storage system does not offer the lowest cost of energy because of the affect of the TES system on plant efficiency. TES Design Assumptions: Nexant [16] developed the TES system costs, solar field return temperatures, and power cycle efficiencies for the analysis. Nexant also provided TES thermal loss assumptions in the study. Table 3 provides general design data for the 6-hour storage system. Table 3 A 6-Hour TES system design for 50-MWe trough plant Number of tanks Height, m Diameter, m Floor, wall, and roof area, m2 Inventory temperature, C Mean insulation temperature, C Thermal conductivity, J/sec-m-°C Insulation thickness, m Tank heat loss, kWt Cold Tank 1 14.0 34.2 3,335.9 292 159 0.0664 0.28 210 Hot Tank 1 14.0 34.7 3,422.1 389 207 0.0716 0.36 246 Parabolic Trough Plant Assumptions: The parabolic trough plant design is based on assumptions for a near-term plant using LS-2 solar collectors and Solel UVAC receivers. General trough plant assumptions are shown in Table 4 for a sample plant with 6 hours of TES and a heat exchanger LMTD of 7°C. Note that the power cycle efficiency is different depending on whether the thermal input comes from the solar field or the TES system. Capital and O&M Cost Assumptions: The capital cost and O&M costs as estimated by the NREL cost models for the 6- hour storage case are shown in Tables 5 and 6. TES Dispatch Strategy: The plant was assumed to operate to dispatch energy to a summer afternoon peak period and a winter evening peak period. The model uses a fairly simple dispatching strategy, which was not fully optimized for each run. An improved dispatch strategy would probably result in reduced dumping of energy and improve the cost of energy for some of the plant configurations. Power Plant Operations: During normal operation at the SEGS plants, the solar fields and the power plant are operated to maximize net solar electric output. The solar field temperature is dropped in the winter because the power plant is operated at a lower load and the higher temperatures are not required to maintain the minimum required steam superheat. In the summer, steam cycle feedwater heaters are often bypassed to reduce the amount of solar field dumping. The turbine cycle is allowed to operate at about 115% of design output when excess solar energy is available. In the TES analysis, we limited the turbine output to 100% of design. We will consider a second case later where the turbine cycle is allowed to go to 115% of design point. 5PDF Image | A Parabolic Trough Solar Power Plant Simulation Model

PDF Search Title:

A Parabolic Trough Solar Power Plant Simulation ModelOriginal File Name Searched:

33209.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |