PDF Publication Title:

Text from PDF Page: 005

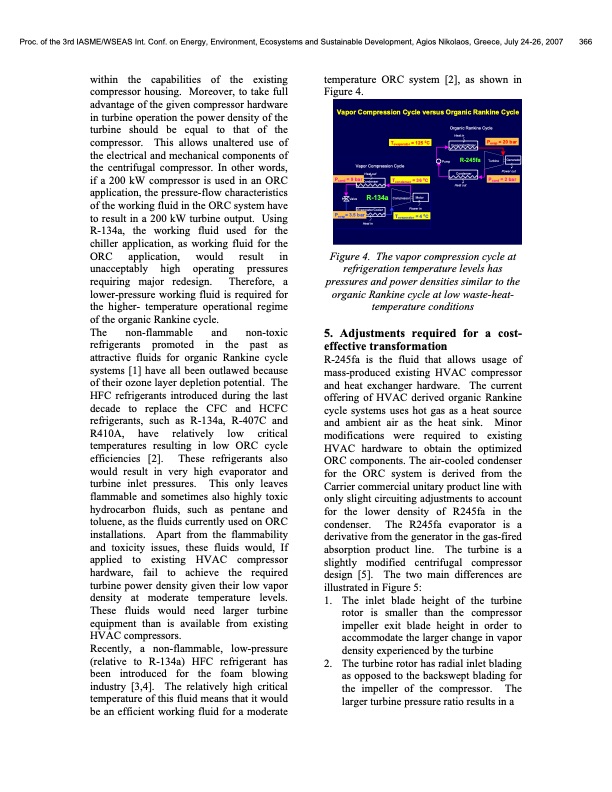

Proc. of the 3rd IASME/WSEAS Int. Conf. on Energy, Environment, Ecosystems and Sustainable Development, Agios Nikolaos, Greece, July 24-26, 2007 366 within the capabilities of the existing compressor housing. Moreover, to take full advantage of the given compressor hardware in turbine operation the power density of the turbine should be equal to that of the compressor. This allows unaltered use of the electrical and mechanical components of the centrifugal compressor. In other words, if a 200 kW compressor is used in an ORC application, the pressure-flow characteristics of the working fluid in the ORC system have to result in a 200 kW turbine output. Using R-134a, the working fluid used for the chiller application, as working fluid for the ORC application, would result in unacceptably high operating pressures requiring major redesign. Therefore, a lower-pressure working fluid is required for the higher- temperature operational regime of the organic Rankine cycle. The non-flammable and non-toxic refrigerants promoted in the past as attractive fluids for organic Rankine cycle systems [1] have all been outlawed because of their ozone layer depletion potential. The HFC refrigerants introduced during the last decade to replace the CFC and HCFC refrigerants, such as R-134a, R-407C and R410A, have relatively low critical temperatures resulting in low ORC cycle efficiencies [2]. These refrigerants also would result in very high evaporator and turbine inlet pressures. This only leaves flammable and sometimes also highly toxic hydrocarbon fluids, such as pentane and toluene, as the fluids currently used on ORC installations. Apart from the flammability and toxicity issues, these fluids would, If applied to existing HVAC compressor hardware, fail to achieve the required turbine power density given their low vapor density at moderate temperature levels. These fluids would need larger turbine equipment than is available from existing HVAC compressors. Recently, a non-flammable, low-pressure (relative to R-134a) HFC refrigerant has been introduced for the foam blowing industry [3,4]. The relatively high critical temperature of this fluid means that it would be an efficient working fluid for a moderate temperature ORC system [2], as shown in Figure 4. Vapor Compression Cycle versus Organic Rankine Cycle Vapor Compression Cycle Heat out Pcond = 9 barCondenser Tcondenser = 36 0C Valve R-134a Compressor Motor Evaporator/Cooler Power in Pevap= 3.5 bar Tevaporator = 4 0C Heat in Tevaporator = 125 0C Heat in Evaporator/Boiler R-245fa Condenser Heat out Pevap = 20 bar Pump Turbine Organic Rankine Cycle Generator Power out Pcond = 2 bar Figure 4. The vapor compression cycle at refrigeration temperature levels has pressures and power densities similar to the organic Rankine cycle at low waste-heat- temperature conditions 5. Adjustments required for a cost- effective transformation R-245fa is the fluid that allows usage of mass-produced existing HVAC compressor and heat exchanger hardware. The current offering of HVAC derived organic Rankine cycle systems uses hot gas as a heat source and ambient air as the heat sink. Minor modifications were required to existing HVAC hardware to obtain the optimized ORC components. The air-cooled condenser for the ORC system is derived from the Carrier commercial unitary product line with only slight circuiting adjustments to account for the lower density of R245fa in the condenser. The R245fa evaporator is a derivative from the generator in the gas-fired absorption product line. The turbine is a slightly modified centrifugal compressor design [5]. The two main differences are illustrated in Figure 5: 1. The inlet blade height of the turbine rotor is smaller than the compressor impeller exit blade height in order to accommodate the larger change in vapor density experienced by the turbine 2. The turbine rotor has radial inlet blading as opposed to the backswept blading for the impeller of the compressor. The larger turbine pressure ratio results in aPDF Image | Concentrating Solar Power 10 MW

PDF Search Title:

Concentrating Solar Power 10 MWOriginal File Name Searched:

562_099.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |