PDF Publication Title:

Text from PDF Page: 004

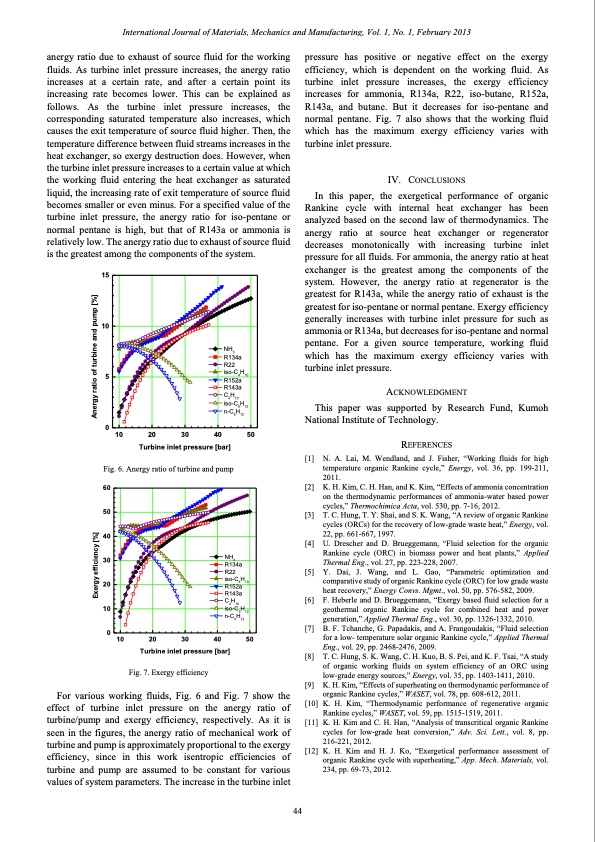

International Journal of Materials, Mechanics and Manufacturing, Vol. 1, No. 1, February 2013 anergy ratio due to exhaust of source fluid for the working fluids. As turbine inlet pressure increases, the anergy ratio increases at a certain rate, and after a certain point its increasing rate becomes lower. This can be explained as follows. As the turbine inlet pressure increases, the corresponding saturated temperature also increases, which causes the exit temperature of source fluid higher. Then, the temperature difference between fluid streams increases in the heat exchanger, so exergy destruction does. However, when the turbine inlet pressure increases to a certain value at which the working fluid entering the heat exchanger as saturated liquid, the increasing rate of exit temperature of source fluid becomes smaller or even minus. For a specified value of the turbine inlet pressure, the anergy ratio for iso-pentane or normal pentane is high, but that of R143a or ammonia is relatively low. The anergy ratio due to exhaust of source fluid is the greatest among the components of the system. 15 10 5 0 10 20 30 40 50 Turbine inlet pressure [bar] Fig. 6. Anergy ratio of turbine and pump 60 50 40 30 20 10 0 10 20 30 40 50 Turbine inlet pressure [bar] Fig. 7. Exergy efficiency For various working fluids, Fig. 6 and Fig. 7 show the effect of turbine inlet pressure on the anergy ratio of turbine/pump and exergy efficiency, respectively. As it is seen in the figures, the anergy ratio of mechanical work of turbine and pump is approximately proportional to the exergy efficiency, since in this work isentropic efficiencies of turbine and pump are assumed to be constant for various values of system parameters. The increase in the turbine inlet pressure has positive or negative effect on the exergy efficiency, which is dependent on the working fluid. As turbine inlet pressure increases, the exergy efficiency increases for ammonia, R134a, R22, iso-butane, R152a, R143a, and butane. But it decreases for iso-pentane and normal pentane. Fig. 7 also shows that the working fluid which has the maximum exergy efficiency varies with turbine inlet pressure. IV. CONCLUSIONS In this paper, the exergetical performance of organic Rankine cycle with internal heat exchanger has been analyzed based on the second law of thermodynamics. The anergy ratio at source heat exchanger or regenerator decreases monotonically with increasing turbine inlet pressure for all fluids. For ammonia, the anergy ratio at heat exchanger is the greatest among the components of the system. However, the anergy ratio at regenerator is the greatest for R143a, while the anergy ratio of exhaust is the greatest for iso-pentane or normal pentane. Exergy efficiency generally increases with turbine inlet pressure for such as ammonia or R134a, but decreases for iso-pentane and normal pentane. For a given source temperature, working fluid which has the maximum exergy efficiency varies with turbine inlet pressure. ACKNOWLEDGMENT This paper was supported by Research Fund, Kumoh National Institute of Technology. REFERENCES [1] N. A. Lai, M. Wendland, and J. Fisher, “Working fluids for high temperature organic Rankine cycle,” Energy, vol. 36, pp. 199-211, 2011. [2] K. H. Kim, C. H. Han, and K. Kim, “Effects of ammonia concentration on the thermodynamic performances of ammonia-water based power cycles,” Thermochimica Acta, vol. 530, pp. 7-16, 2012. [3] T. C. Hung, T. Y. Shai, and S. K. Wang, “A review of organic Rankine cycles (ORCs) for the recovery of low-grade waste heat,” Energy, vol. 22, pp. 661-667, 1997. [4] U. Drescher and D. Brueggemann, “Fluid selection for the organic Rankine cycle (ORC) in biomass power and heat plants,” Applied Thermal Eng., vol. 27, pp. 223-228, 2007. [5] Y. Dai, J. Wang, and L. Gao, “Parametric optimization and comparative study of organic Rankine cycle (ORC) for low grade waste heat recovery,” Energy Convs. Mgmt., vol. 50, pp. 576-582, 2009. [6] F. Heberle and D. Brueggemann, “Exergy based fluid selection for a geothermal organic Rankine cycle for combined heat and power generation,” Applied Thermal Eng., vol. 30, pp. 1326-1332, 2010. [7] B. F. Tchanche, G. Papadakis, and A. Frangoudakis, “Fluid selection for a low- temperature solar organic Rankine cycle,” Applied Thermal Eng., vol. 29, pp. 2468-2476, 2009. [8] T. C. Hung, S. K. Wang, C. H. Kuo, B. S. Pei, and K. F. Tsai, “A study of organic working fluids on system efficiency of an ORC using low-grade energy sources,” Energy, vol. 35, pp. 1403-1411, 2010. [9] K. H. Kim, “Effects of superheating on thermodynamic performance of organic Rankine cycles,” WASET, vol. 78, pp. 608-612, 2011. [10] K. H. Kim, “Thermodynamic performance of regenerative organic Rankine cycles,” WASET, vol. 59, pp. 1515-1519, 2011. [11] K. H. Kim and C. H. Han, “Analysis of transcritical organic Rankine cycles for low-grade heat conversion,” Adv. Sci. Lett., vol. 8, pp. 216-221, 2012. [12] K. H. Kim and H. J. Ko, “Exergetical performance assessment of organic Rankine cycle with superheating,” App. Mech. Materials, vol. 234, pp. 69-73, 2012. NH3 R134a R22 iso-C4H10 R152a R143a C4H10 iso-C5H12 n-C5H12 NH3 R134a R22 iso-C4H10 R152a R143a C4H10 iso-C5H12 n-C5H12 44 Exergy efficiency [%] Anergy ratio of turbine and pump [%]PDF Image | Exergy Analysis of Organic Rankine Cycle with Internal

PDF Search Title:

Exergy Analysis of Organic Rankine Cycle with InternalOriginal File Name Searched:

009_E022.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |